Build List

-

Active Filters:

a

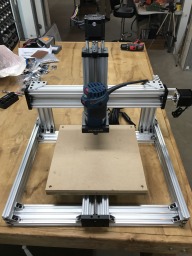

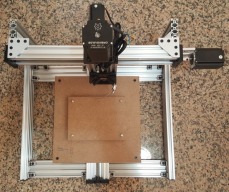

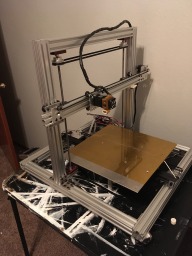

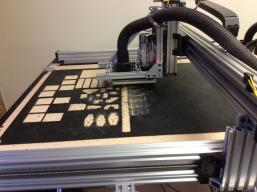

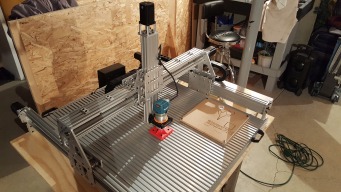

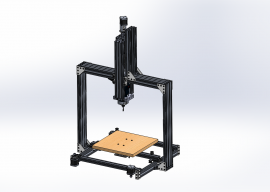

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

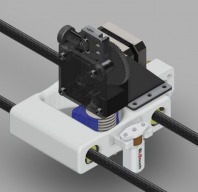

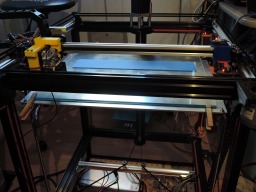

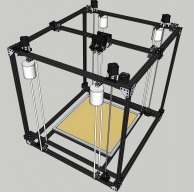

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

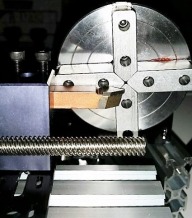

OBlathe

A simple wood turning lathe.

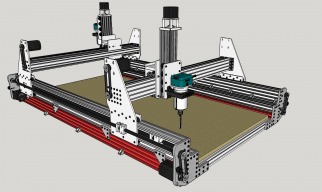

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

C beam xl

I would recommend this challenge to any woodworker looking for something new.

Build Author

THE LINK

Views

5193

Build Author

THE LINK

Views

5193

2020 First build.

Probably cheapest DIY build youl see.

Vertek CNC - 1000mm x 750mm Linear Rail on C Beam

C beam gantry with steel guide rails!

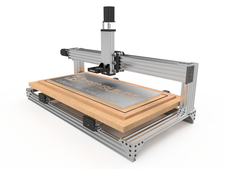

Voxel OX Based Build

Building upon the great work done by Marshall Peck and others. I have started a new build.

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

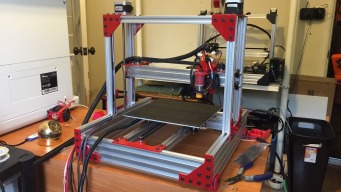

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

Build Author

Pol Feliu

Views

9371

Build Author

Pol Feliu

Views

9371

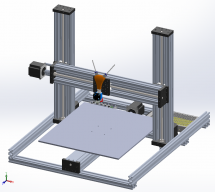

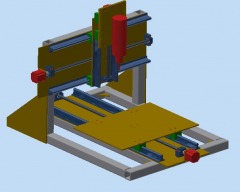

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

islahcnc

Views

4551

Build Author

islahcnc

Views

4551

islahcnc&design

I will post soon some more details.

Build Author

JerryD

Views

5464

Build Author

JerryD

Views

5464

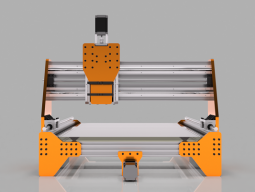

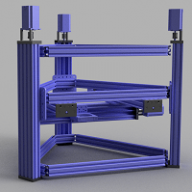

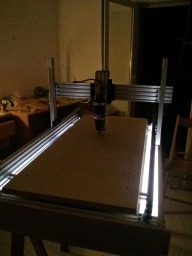

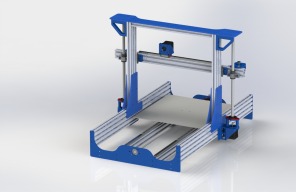

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Polar Bot

Polar Bot which used to depress buttons

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

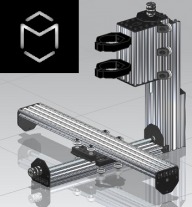

M^3

Views

22331

Build Author

M^3

Views

22331

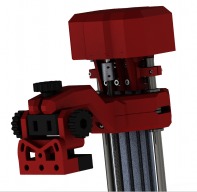

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Justin Butler

Views

9637

Build Author

Justin Butler

Views

9637

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

Build Author

Robert Bailey

Views

29627

Build Author

Robert Bailey

Views

29627

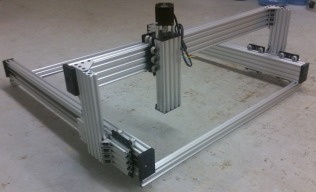

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

Karan Singh Sisodia

Views

6484

Build Author

Karan Singh Sisodia

Views

6484

My Home made CNC

Home Made CNC Router from Scrape

Steel Frame CNC Router

A scratch built steel frame CNC Router.

DIY LED acrylic lamp

This is a simple lamp using only 2 LEDs & 2 AAA batteries.

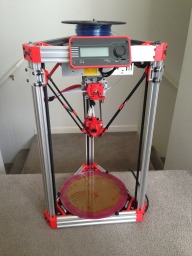

Delta-Six

Super rigid Delta printer, using 20X40 V-Slot

Steel Frame 3D Printer

A steel framed 3D printer using a similar design with my CNC Router.

Build Author

Sonny Lowe

Views

7176

Build Author

Sonny Lowe

Views

7176

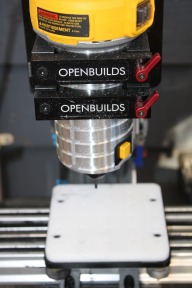

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Build Author

sgspenceley

Views

9359

Build Author

sgspenceley

Views

9359

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Lathe 4" x 40"

This is a lathe. I do not plan on making parts for NASA, but I want to be able to turn, face and bore things like wood, brass, aluminum and plastics.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

CNC Planning

Reusing parts to build a CNC - planning stage

Build Author

Venturebit

Views

14254

Build Author

Venturebit

Views

14254

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Build Author

Fabio Orsi

Views

7088

Build Author

Fabio Orsi

Views

7088

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

MiniMill

Building a small mill to match my 7x12 lathe.

Build Author

mirage335

Views

7496

Build Author

mirage335

Views

7496

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Kool Bot

Mid range build.

Build Author

evgeny156

Views

7478

Build Author

evgeny156

Views

7478

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Hisha

Views

5237

Build Author

Hisha

Views

5237

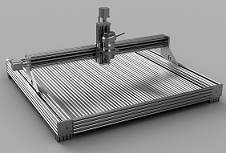

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

Limine3D

Views

8768

Build Author

Limine3D

Views

8768

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Anglesachse

Views

29420

Build Author

Anglesachse

Views

29420

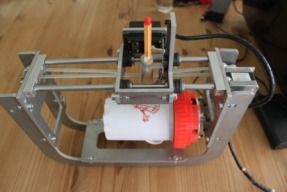

Pot Plotter

My version of the Mug Plotter designed by Teed http://edinburghhacklab.com/ . Also used the Eibotboard from the original eggbot from evilmadscientists http://shop.evilmadscientist.com/partsmenu/188-ebb A huge thanks to Hexitex for his brilliant Four jaw chuck http://www.thingiverse.com/thing:5791

Build Author

Mark Carew

Views

51579

Build Author

Mark Carew

Views

51579

V-Slot SphereBot

This SphereBot is based on the EggBot which is an open-source art robot (drawbot) that can draw on spherical or egg-shaped objects.

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

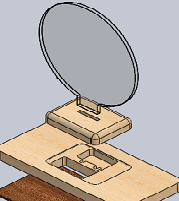

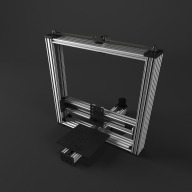

C-Beam based modular Resin Printer

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

Build Author

Steven Sampson

Views

11120

Build Author

Steven Sampson

Views

11120

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

mikev

Views

8776

Build Author

mikev

Views

8776

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

V-Slot Linear Actuator Bundle

v-slot linear actuator build.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Tomas F Uribe

Views

5475

Build Author

Tomas F Uribe

Views

5475

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

COMsulting

Views

10239

Build Author

COMsulting

Views

10239

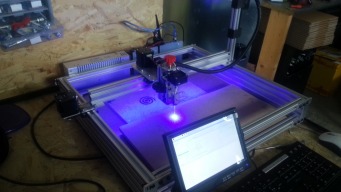

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Build Author

J-Wahl Dezign

Views

9279

Build Author

J-Wahl Dezign

Views

9279

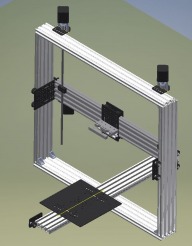

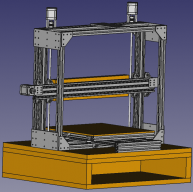

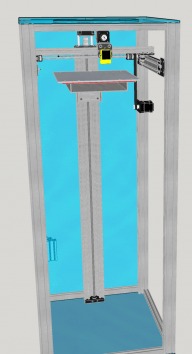

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

Thair.nl

Views

3969

Build Author

Thair.nl

Views

3969

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Build Author

eddyg

Views

5151

Build Author

eddyg

Views

5151

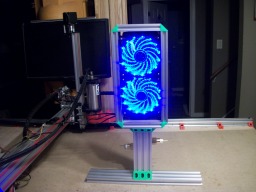

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Build Author

nschreiber0813

Views

5654

Build Author

nschreiber0813

Views

5654

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

Build Author

adamcooks

Views

43606

Build Author

adamcooks

Views

43606

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Jonathon Duerig

Views

7368

Build Author

Jonathon Duerig

Views

7368

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

Limine3D

Views

22019

Build Author

Limine3D

Views

22019

M3Delta

Delta printer designed in sketchup and includes an adjustable bed.

Suitcase Vacuumformer

Quick overview of my build up for a vacuum former that is self contained, portable and fairly easy to build.

Build Author

Peter Van Der Walt

Views

7725

Build Author

Peter Van Der Walt

Views

7725

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

Rich Bowen

Views

3950

Build Author

Rich Bowen

Views

3950

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

The Laserbox

A low cost and easy to build laser cutter based on 2.8w laser diode .

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

Makerparts.ca Prusa i3Pro 300

Concept for a Prusa i3 made from Cbeam Extrusion. X & Y using GT2 Belts, Z using Acme Screws Goal is to build a simple. and very Solid Printer Single Z Motor to keep the Z Screws in Sync. (Might require Geared Nema 17) 12" x 12" x 12" Build volume Nema 17's

Build Author

Matt Barile

Views

7788

Build Author

Matt Barile

Views

7788

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

3D Meister

Views

5732

Build Author

3D Meister

Views

5732

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Build Author

McAdam

Views

3856

Build Author

McAdam

Views

3856

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Talos3D

In Greek mythology, Talos (/ˈteɪlɒs/;[1] Greek: Τάλως, Talōs) was a giant man of bronze made by Hephaestus (the Greek god of fire, metalworking, craftsmen and blacksmiths) who protected Europa in Crete from pirates and invaders. He circled the island's shores three times daily.

Build Author

Robert Huxford

Views

4162

Build Author

Robert Huxford

Views

4162

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

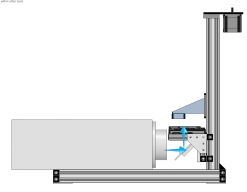

Touchsensor assembly machine

This is a handy machine to assemble touch sensors into display frame.

Build Author

Dmknerr

Views

5333

Build Author

Dmknerr

Views

5333

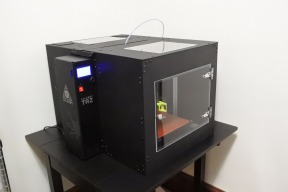

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Spindle cooling setup

Cooling system for water cooled spindle.

Build Author

Anthony Bolgar

Views

12268

Build Author

Anthony Bolgar

Views

12268

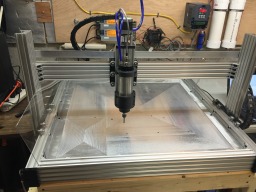

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

Build Author

Anthony Bolgar

Views

5861

Build Author

Anthony Bolgar

Views

5861

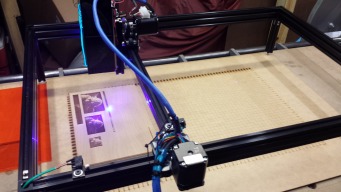

Air assist/fume collector for Diode Laser Engraver

This is a work in progress

Build Author

chenderson

Views

13049

Build Author

chenderson

Views

13049

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

Build Author

DistortedDesigns

Views

34386

Build Author

DistortedDesigns

Views

34386

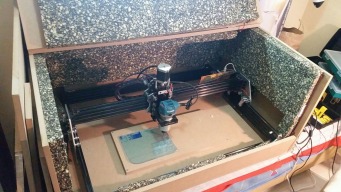

Project Death Star - DistortedDesigns Laser Engraver

2 watt Laser Engraver, Simple, Fairly Low Cost, and Portable

My 1st Build - Delta Printer with 3 filament hot end

The build area will be fully enclosed. I anticipate using primarily ABS, and have interest in the soluble support materials as well. The main components to date include: OPENBUILDS - 3 x C-Beam™ Linear Actuator Bundle, 1000 mm, w/ Included NEMA23 Motor) Extruders (3) - [Sintron] 1.75mm Mini All Metal MK8 Extruder Hot End - reprap diamond Control board - RUMBA Stepper drivers - DRV8825 StepStick Power supply - eTopxizu 12v 30a

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

blackcat3d printer

in construction ! chassis vslot 80x20 & 20x20 & 60x80 (Z) home made plates with whells polycarbonate build volume environ, 750x300x200 2 ed3d v6 volcano nozzles 0.8mm & 0.6 + titan extrudeurs rumba bord + auto levelling ip camera home made heat bed aluminium 5mm + glass + heat air chamber 6 doors plexiglass......

KALΔIS OPEN SLA

Modular easy to adjust scale of the entire build Tablet/LCD monitor SLA 3d Printer.

Build Author

Keteland

Views

10850

Build Author

Keteland

Views

10850

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Makerparts

Views

7874

Build Author

Makerparts

Views

7874

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

Wifi'not

A simple made hideaway for ugly electronics