Cartesian Style CNC

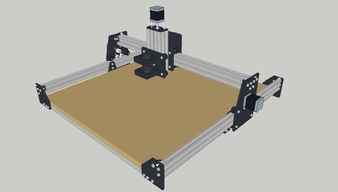

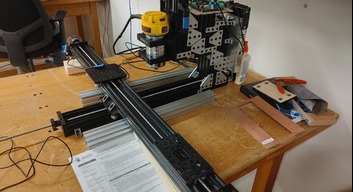

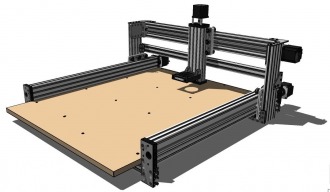

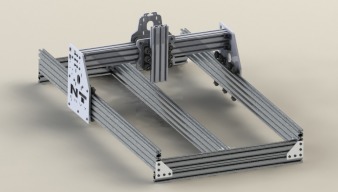

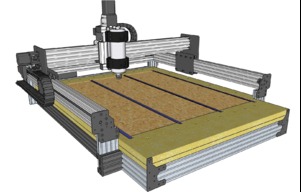

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

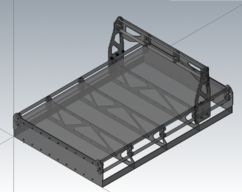

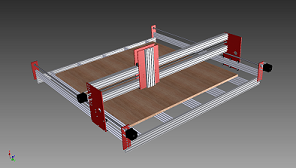

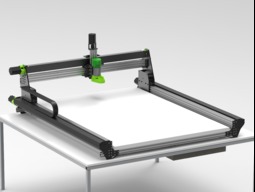

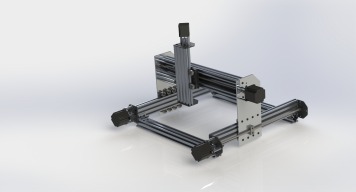

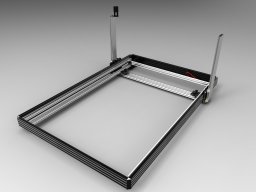

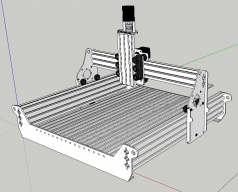

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

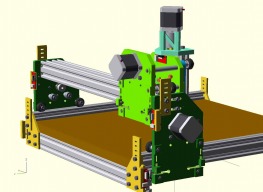

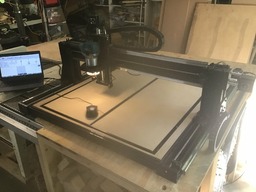

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Build Author

Andre Cooke

Views

17635

Build Author

Andre Cooke

Views

17635

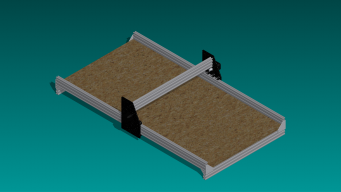

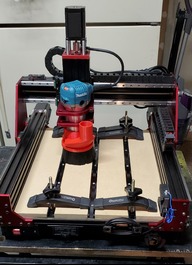

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

spark2

Views

5707

Build Author

spark2

Views

5707

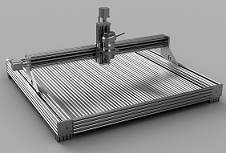

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

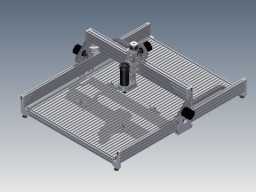

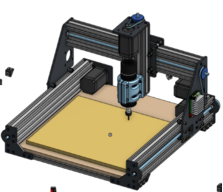

Something a Tad different

Future CNC router kit design

Build Author

Axnfell

Views

3115

Build Author

Axnfell

Views

3115

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

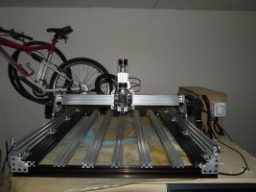

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

C-CNC

Views

16287

Build Author

C-CNC

Views

16287

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

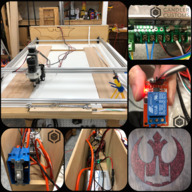

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Build Author

msdosfx

Views

6178

Build Author

msdosfx

Views

6178

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

Build Author

RV6APilot

Views

4244

Build Author

RV6APilot

Views

4244

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

tmadrms

Views

7748

Build Author

tmadrms

Views

7748

C-Beam Mods

C-beam machine mods.

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Build Author

Wes Dwight

Views

7773

Build Author

Wes Dwight

Views

7773

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

Build Author

Stokrotka74

Views

6962

Build Author

Stokrotka74

Views

6962

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Workbee with less irritations

My workbee build with some add ons

Black gear 1500X3000

My cnc update and rebuild.

Build Author

Colin Russon

Views

8715

Build Author

Colin Russon

Views

8715

RoboFoamCutter

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

spunks.cam

Design of a multifunctional CNC machine.

Build Author

richthorn

Views

8268

Build Author

richthorn

Views

8268

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Build Author

DiggerJ

Views

8795

Build Author

DiggerJ

Views

8795

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

d0rk1e

Views

7785

Build Author

d0rk1e

Views

7785

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Custom OX Build

Inspired by the original OX by Mark Carew, this is my Custom OX. Many small changes, additions, and upgrades. Build is in progress and this post will be updated regularly with photos. Enjoy!

Viking OX

My OX cnc upgrade.

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

Build Author

mikev

Views

8603

Build Author

mikev

Views

8603

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

Hisha

Views

5068

Build Author

Hisha

Views

5068

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

CandlerCustoms

Views

5579

Build Author

CandlerCustoms

Views

5579

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

Camvec

Views

6288

Build Author

Camvec

Views

6288

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

TurfnSurf

Views

6227

Build Author

TurfnSurf

Views

6227

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

crnrstndes

Views

4253

Build Author

crnrstndes

Views

4253

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

rob4cnc

Views

4036

Build Author

rob4cnc

Views

4036

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

Craig Hollabaugh

Views

4910

Build Author

Craig Hollabaugh

Views

4910

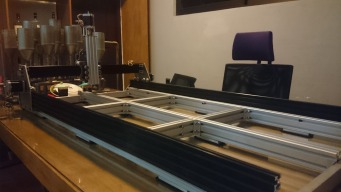

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Jay Almers

Views

8058

Build Author

Jay Almers

Views

8058

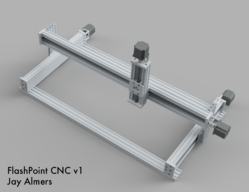

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Bessy 4x4

I found this to be a very fun exercise in building Bessy and will continue to improve her in the future.

The Beast

1000mm x 1000mm linear rails, double gantry, build in Process... more to come

Monster-not-so-mini-mill

My Minimill hit the gym, and isn't so mini anymore

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Aluminium OX - Canada

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

Birdie CNC

OpenBuilds CNC 500x500

Aluminium Router From Dubai

Another modification on the OX

Build Author

Hytech2k

Views

6961

Build Author

Hytech2k

Views

6961

Micro Ox 2 x 2

Micro Ox Build

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Build Author

Donald D. Parker

Views

5671

Build Author

Donald D. Parker

Views

5671

BABE - CanUSA Blue OX, bigger than the average OX

This is a basic description of my OX-like build of Babe, Paul Bunyan's Blue Ox. It is a work in progress. The idea has been germinating for about 4 years, with several twists and turns and false starts along the way.

Build Author

inhan

Views

6215

Build Author

inhan

Views

6215

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Build Author

Justin Butler

Views

9251

Build Author

Justin Butler

Views

9251

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Build Author

Hussein Dermay

Views

6531

Build Author

Hussein Dermay

Views

6531

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

My Little Mashup

A mixed drive, PI Controlled machine

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Build Author

Stan Howe

Views

3361

Build Author

Stan Howe

Views

3361

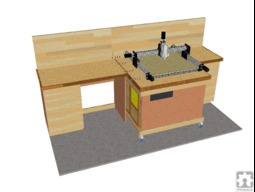

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

KronBjorn

Views

4480

Build Author

KronBjorn

Views

4480

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Build Author

Fábio Pires

Views

7068

Build Author

Fábio Pires

Views

7068

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

75x75

Simple cnc with 5mm steel plates.

LEAD CNC 1010 Laser Modification

Easy All-in-One Laser and Mounting Kit for your Openbuilds CNC.

Cnc Router 3000 x 1000 mm

In progress

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

Build Author

Paul Amelang

Views

5738

Build Author

Paul Amelang

Views

5738

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

1010 with linear rails

Has a 700 by 700 cutting area and is very stable

Build Author

BCulbertson

Views

5142

Build Author

BCulbertson

Views

5142

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Router / Plasma Prototype Build

this is my first attempt at a CNC Table

Build Author

Pendragon

Views

10329

Build Author

Pendragon

Views

10329

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

ROUX - A Routy-OX Hybrid

ROUX is a 2'x4' CNC that can be easily handbuilt without an existing mill and removes the need to buy generic plates for the Routy. A simpler, more refined machine.

Build Author

Bear

Views

11068

Build Author

Bear

Views

11068

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

CNC NT

This is our first CNC project is based on OX CNC. We show you some pictures about our progress. We finished assembly design, software test and drivers test, now we are building the machine.

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Custom Ski and Snowboard CNC for a High School Woodwhop

A Custom size CNC to make custom skis and snowboards

Build Author

openhardwarecoza

Views

7141

Build Author

openhardwarecoza

Views

7141

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Ooznest OX CNC Build

Ooznest OX CNC build

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.