Build List

-

Active Filters:

a

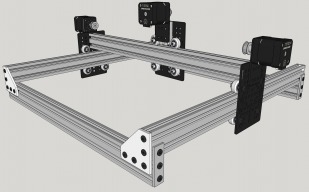

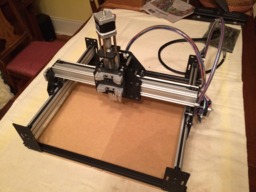

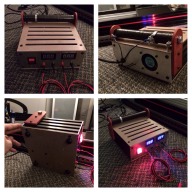

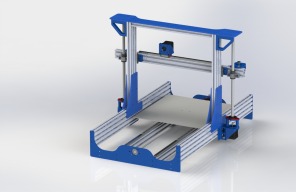

Small Laser Engraver Concept

Low cost Laser Engraver build using all off-the-shelf components.

KALΔIS OPEN SLA

Modular easy to adjust scale of the entire build Tablet/LCD monitor SLA 3d Printer.

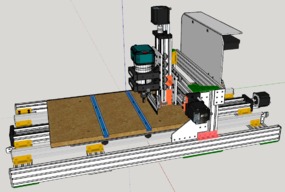

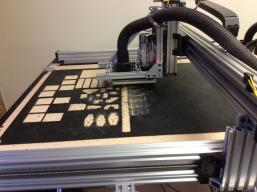

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

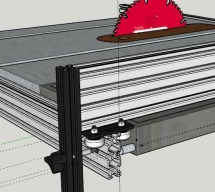

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

Build Author

chenderson

Views

12838

Build Author

chenderson

Views

12838

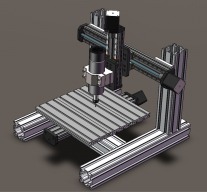

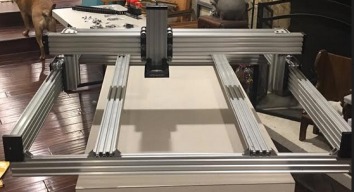

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

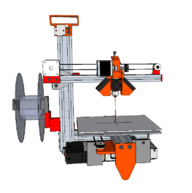

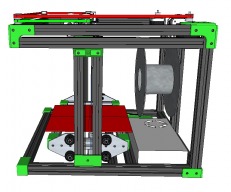

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

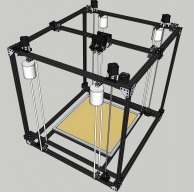

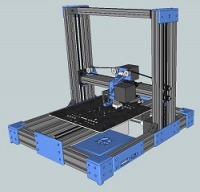

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

Build Author

pek

Views

6458

Build Author

pek

Views

6458

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

Build Author

Joerharris

Views

6558

Build Author

Joerharris

Views

6558

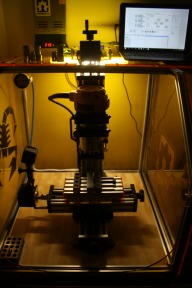

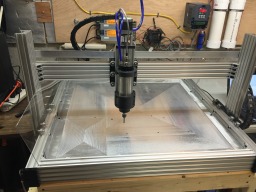

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Rob Mahan

Views

13723

Build Author

Rob Mahan

Views

13723

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Glenn Weston

Views

11415

Build Author

Glenn Weston

Views

11415

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Build Author

Tommy Williamson

Views

6966

Build Author

Tommy Williamson

Views

6966

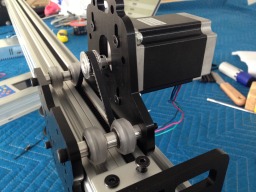

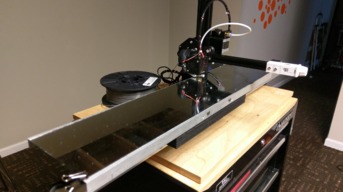

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

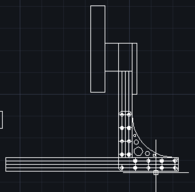

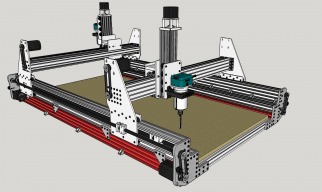

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Build Author

deltajegga

Views

9885

Build Author

deltajegga

Views

9885

THE delta

probably as big as you'd want it...

Build Author

Joe Young

Views

5880

Build Author

Joe Young

Views

5880

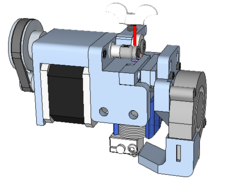

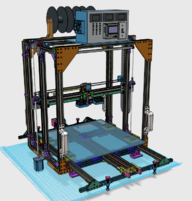

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

CoreCube3D

Views

21982

Build Author

CoreCube3D

Views

21982

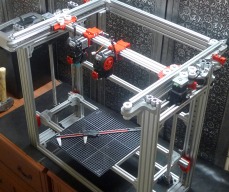

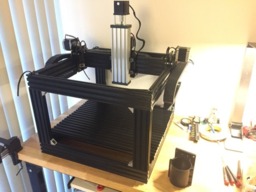

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

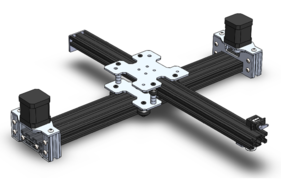

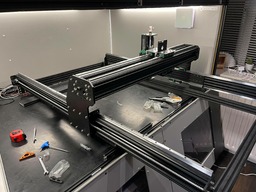

x_y_module laser engraver

low cost 2 axis cnc laser, really portable and easily expandable

Simpl3rBot

A framing design for cantilever style printers

Build Author

Jason Moore

Views

13052

Build Author

Jason Moore

Views

13052

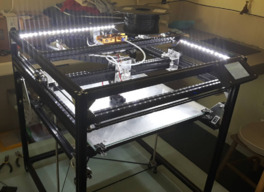

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Build Author

Mark Carew

Views

93011

Build Author

Mark Carew

Views

93011

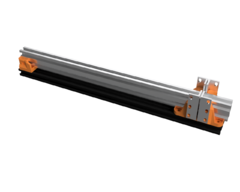

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

Build Author

Mark Carew

Views

64706

Build Author

Mark Carew

Views

64706

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Build Author

Rakmup

Views

41357

Build Author

Rakmup

Views

41357

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

Build Author

Keith Davis

Views

17618

Build Author

Keith Davis

Views

17618

OneZ

OneZ gets it's name from it's most unique feature - only motor for the Z axis while maintaining the stability of two bearing guides for the Z axis. Reduction to one Z motor eliminates need for auto bed leveling.

OX-Based Self-Contaned HVLP Spray Booth

A CNC HVLP spray booth based on OX.

Build Author

Keith Davis

Views

20672

Build Author

Keith Davis

Views

20672

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

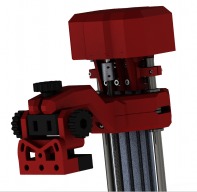

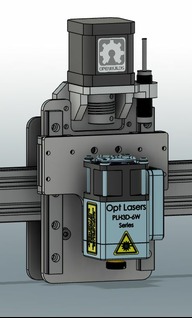

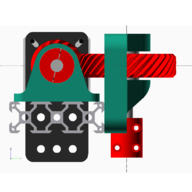

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

The Almost Perfect 3 Way Mitre (with MakerLinks)

A quick and easy way to make a 3-way mitered corner using MakerLinks

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

100w Laser Cutter Build Log

I rebuild my 2 meter tall 3D printer into a 100w laser cutter

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

New 2 watt laser platform

Acro based 2 watt laser platform

Build Author

GDanger117

Views

12326

Build Author

GDanger117

Views

12326

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Keith Davis

Views

5429

Build Author

Keith Davis

Views

5429

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Draw bot core xy

In the design stage. Help guide.

Build Author

BNMaker

Views

11960

Build Author

BNMaker

Views

11960

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

Build Author

Mark Carew

Views

33766

Build Author

Mark Carew

Views

33766

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

obmilllivebuild

Views

12281

Build Author

obmilllivebuild

Views

12281

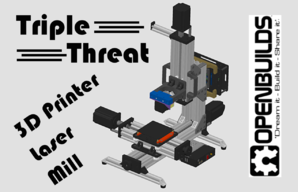

Live OpenBuilds MiniMill -> MiniPrint/Laser Conversion Demo @ MRRF2019

Transformation of an OpenBuilds Mini Mill into a convertible 3D printer / CNC mill with interchangeable tooling. Maybe a bonus conversion TBD.

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

Build Author

GinoTheCop

Views

14610

Build Author

GinoTheCop

Views

14610

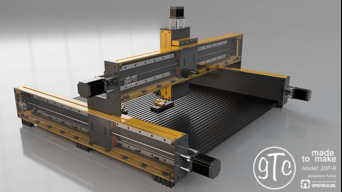

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

Black Box/ Power supply brackets

This items are so cool that they need to be together, so I decided to create brackets that connect both pieces together

Build Author

Damian V-SLOT Poland

Views

15756

Build Author

Damian V-SLOT Poland

Views

15756

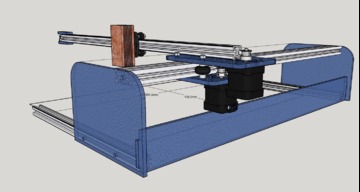

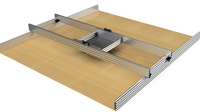

Router Sled V1.1 V-SLOT

We want to present you the new design of the device which is Router Sled. The whole structure is made of aluminum elements and ensures good quality of the device. We used V-SLOT aluminum profiles and OpenBuilds accessories for the construction. The instructional video can be found on our YouTube channel (subtitles in English soon)

Build Author

Corey Corbin

Views

7538

Build Author

Corey Corbin

Views

7538

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

OpenBuilds

Views

29504

Build Author

OpenBuilds

Views

29504

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

CNCGear

Views

10613

Build Author

CNCGear

Views

10613

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Desktop CNC

A desktop Cartesian CNC router

Dedicated Compact Rotary Axis Laser Engraver

Compact Dedicated Rotary Axis Laser Engraver

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

Build Author

Mark Carew

Views

51093

Build Author

Mark Carew

Views

51093

V-Slot SphereBot

This SphereBot is based on the EggBot which is an open-source art robot (drawbot) that can draw on spherical or egg-shaped objects.

Build Author

Mark Carew

Views

132153

Build Author

Mark Carew

Views

132153

V-Slot® NEMA 17 Linear Actuator (Belt Driven)

Quick and Simple V-Slot Gantry System. This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts. You can mount this system an many ways so be sure to download the example models.

Camera slider for stacking focus

This is just a small project to get use to the OpenBuild products.

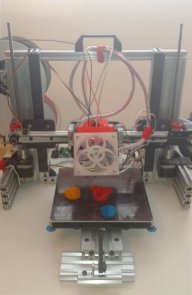

Dual Extruder 3D Printer and Laser Cutter combo

Dual extruder 3D printer and laser cutter.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

John J Talavera

Views

18682

Build Author

John J Talavera

Views

18682

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Mini lathe CNC Conversion - Work in progress

My on going build of CNC Mini Lathe

BldrBot Pro

A completely belt driven cartesian design with a center mounted X motor. This is a very compact, rugged design.

DIY anodizing power supply

How to make your own anodizing power supply on a budget

Build Author

Mark Carew

Views

126952

Build Author

Mark Carew

Views

126952

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

My Second CNC

In short...this was a fun project.

Build Author

Teflon4

Views

15927

Build Author

Teflon4

Views

15927

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

Touchsensor assembly machine

This is a handy machine to assemble touch sensors into display frame.

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

Build Author

UltiBots

Views

10556

Build Author

UltiBots

Views

10556

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

Build Author

crystaldragon141

Views

6561

Build Author

crystaldragon141

Views

6561

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Build Author

sgspenceley

Views

8954

Build Author

sgspenceley

Views

8954

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

2 GANTRY CNC HOTWIRE MACHINE

A 2 independent gantry affordable hotwire machine.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

Hisha

Views

8856

Build Author

Hisha

Views

8856

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

Build Author

megashub

Views

24222

Build Author

megashub

Views

24222

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Automatic Sprayer

Automatic spray machine.

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Carl Siren

Views

7641

Build Author

Carl Siren

Views

7641

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Calotype

Views

3594

Build Author

Calotype

Views

3594

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

Lasersc

Views

10458

Build Author

Lasersc

Views

10458

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

pedrofernandez

Views

7914

Build Author

pedrofernandez

Views

7914

ACRO 20x20

The Acro Laser Machine Build

Build Author

thehans

Views

6647

Build Author

thehans

Views

6647

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

Mark Carew

Views

54749

Build Author

Mark Carew

Views

54749

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Build Author

reef

Views

11960

Build Author

reef

Views

11960

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Build Author

Luke Cunningham

Views

5896

Build Author

Luke Cunningham

Views

5896

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Rob Taylor

Views

10921

Build Author

Rob Taylor

Views

10921

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

Bob Darrow

Views

10090

Build Author

Bob Darrow

Views

10090

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Build Author

pedrofernandez

Views

10011

Build Author

pedrofernandez

Views

10011

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser