Build List

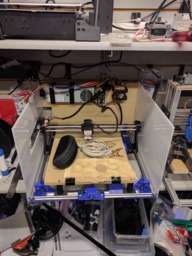

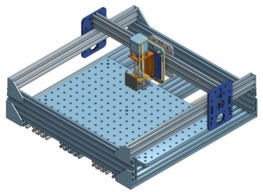

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

jpjoshua

Views

13949

Build Author

jpjoshua

Views

13949

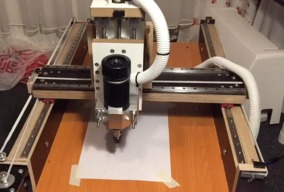

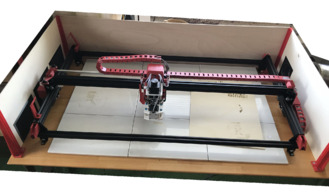

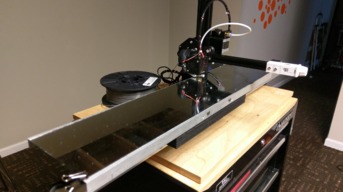

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

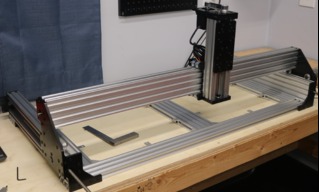

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

ChrisViral

Views

7425

Build Author

ChrisViral

Views

7425

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

Mark Carew

Views

34546

Build Author

Mark Carew

Views

34546

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

Mark Carew

Views

79123

Build Author

Mark Carew

Views

79123

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

28886

Build Author

Mark Carew

Views

28886

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Makerparts Mpro Slider System

Makerparts.ca MPro Camera Slider System

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

Build Author

Todd Brous

Views

5978

Build Author

Todd Brous

Views

5978

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

Build Author

Rat Rig

Views

32425

Build Author

Rat Rig

Views

32425

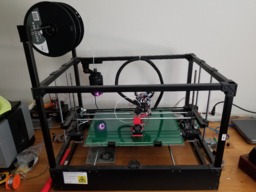

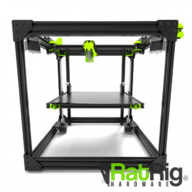

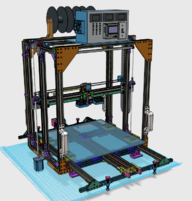

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

Mark Carew

Views

26225

Build Author

Mark Carew

Views

26225

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

reef

Views

12356

Build Author

reef

Views

12356

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

JerwanDavis

Views

6338

Build Author

JerwanDavis

Views

6338

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Mark Carew

Views

17523

Build Author

Mark Carew

Views

17523

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Mark Carew

Views

19143

Build Author

Mark Carew

Views

19143

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Build Author

Mark Rehorst

Views

10407

Build Author

Mark Rehorst

Views

10407

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Mark Carew

Views

19013

Build Author

Mark Carew

Views

19013

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Andreas Bockert

Views

12303

Build Author

Andreas Bockert

Views

12303

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Butterfly 3DP V 1.0

tronxy x3 like

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

stepper

Views

4744

Build Author

stepper

Views

4744

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Galvos

3d printable galvos

Build Author

Hilleke

Views

8069

Build Author

Hilleke

Views

8069

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

Build Author

mytechno3d

Views

15877

Build Author

mytechno3d

Views

15877

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

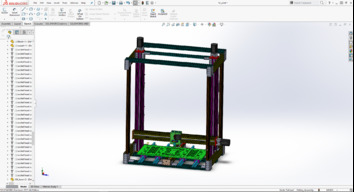

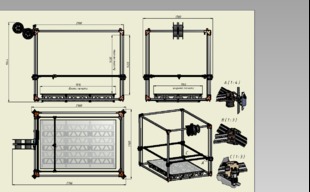

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

SCYBUCK

Views

5281

Build Author

SCYBUCK

Views

5281

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Jones

Views

4166

Build Author

Jones

Views

4166

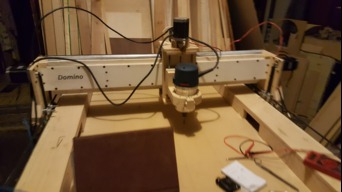

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

My Little Mashup

A mixed drive, PI Controlled machine

Build Author

Luke Cunningham

Views

6046

Build Author

Luke Cunningham

Views

6046

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Rob Taylor

Views

11325

Build Author

Rob Taylor

Views

11325

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Router for speargun hobby

First router build for speargun fabrication

Build Author

C-CNC

Views

16865

Build Author

C-CNC

Views

16865

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Build Author

Bob Darrow

Views

10602

Build Author

Bob Darrow

Views

10602

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Phil's MiniMill

A quick little mini mill build

Build Author

MrMojoRisin

Views

7837

Build Author

MrMojoRisin

Views

7837

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

CNC by MagicMarcus

CNC variation about Sphinx.

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

Build Author

pedrofernandez

Views

10254

Build Author

pedrofernandez

Views

10254

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

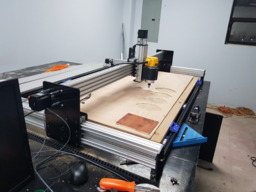

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Build Author

Mark Carew

Views

6371

Build Author

Mark Carew

Views

6371

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Mark Carew

Views

29350

Build Author

Mark Carew

Views

29350

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

Kyo

Views

46884

Build Author

Kyo

Views

46884

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Build Author

Mark Carew

Views

9395

Build Author

Mark Carew

Views

9395

OpenBuilds PowerCase

A simple to assemble, super clean and safe PSU case solution that fits into the OpenBuilds wire management ecosystem

Kraken Core-XY Printer

Core-XY build witha quad nozzle

Build Author

deltajegga

Views

10160

Build Author

deltajegga

Views

10160

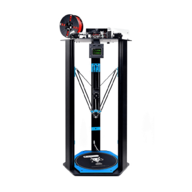

THE delta

probably as big as you'd want it...

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

RobFromLDMS

Views

5515

Build Author

RobFromLDMS

Views

5515

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Build Author

James Evanko

Views

5117

Build Author

James Evanko

Views

5117

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

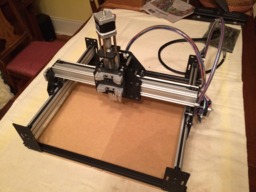

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

thinman

Views

9065

Build Author

thinman

Views

9065

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

Small Slot Cutter

A build to cut .008 inch slots into JB Weld.

Laser cutter

Full aluminium profiles construction. Synrad 50w CO2 laser. Ruida controller. Yaskawa servo motors

Build Author

joetemus

Views

7147

Build Author

joetemus

Views

7147

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Build Author

Craig Hollabaugh

Views

5172

Build Author

Craig Hollabaugh

Views

5172

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Vin1027

Views

7575

Build Author

Vin1027

Views

7575

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Vegard Humlen

Views

5247

Build Author

Vegard Humlen

Views

5247

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

Build Author

Bikes and Beer

Views

5082

Build Author

Bikes and Beer

Views

5082

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

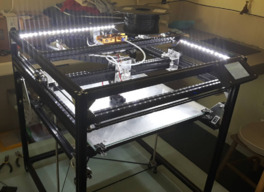

SMD Pick and place machine - Smoothieboard/OpenPnp

A dual head PNP machine that uses Openbuilds hardware, a Smoothieboard controller, dual camera vision, automatic/drag feeders, and OpenPnp.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Troy Proffitt

Views

29578

Build Author

Troy Proffitt

Views

29578

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Spark Concepts

Views

17263

Build Author

Spark Concepts

Views

17263

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

Large 3D Printer 5ft by 5ft print bed

New ultra large 3D Printer design. I'm calling it the AutoCrafter

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

Pick and place

Pick and place based on the Openbuilds ACRO 20x20

Build Author

CoreCube3D

Views

22689

Build Author

CoreCube3D

Views

22689

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

Build Author

Christian James

Views

10588

Build Author

Christian James

Views

10588

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

Jay Almers

Views

8438

Build Author

Jay Almers

Views

8438

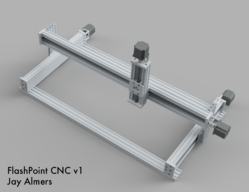

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Cortellini

Views

5820

Build Author

Cortellini

Views

5820

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Project Infinity co2 laser

1m x 1.8m 60w co2 laser build.

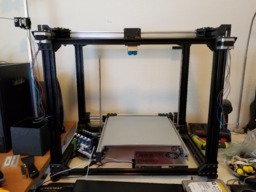

Big a** printer

In-progress 500x500x1800

Build Author

Doug Rowley

Views

4489

Build Author

Doug Rowley

Views

4489

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Build Author

patnap71

Views

7101

Build Author

patnap71

Views

7101

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

msdosfx

Views

6365

Build Author

msdosfx

Views

6365

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.