Build List

-

Active Filters:

be

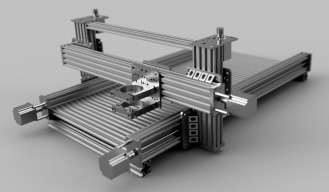

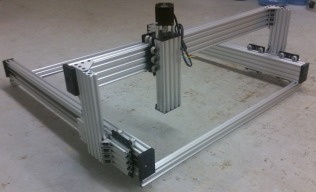

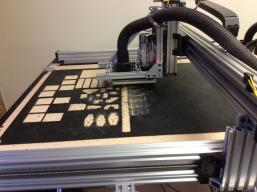

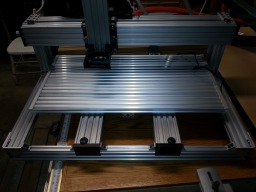

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

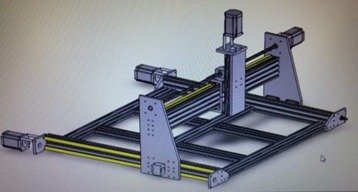

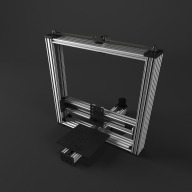

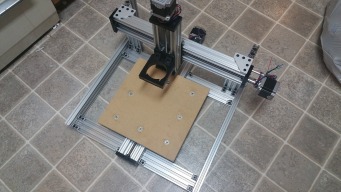

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Hussein Dermay

Views

6735

Build Author

Hussein Dermay

Views

6735

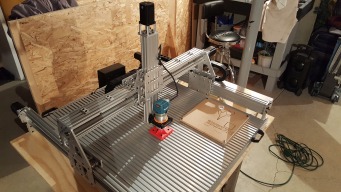

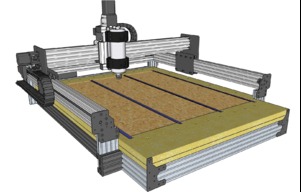

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

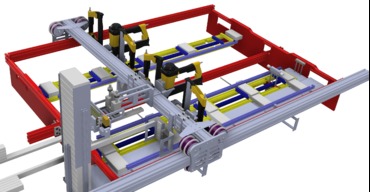

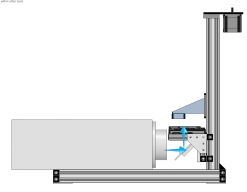

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

C_Beam Hammerhead 5x

setup for learning 5x

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

Axnfell

Views

3238

Build Author

Axnfell

Views

3238

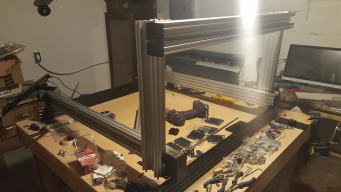

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

Janis93

Views

16035

Build Author

Janis93

Views

16035

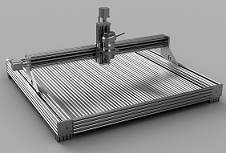

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

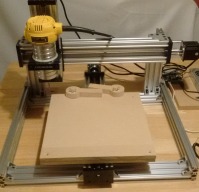

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

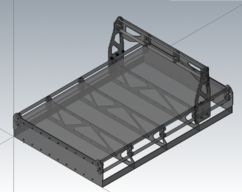

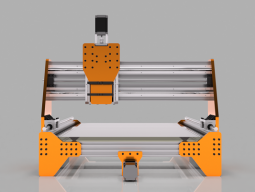

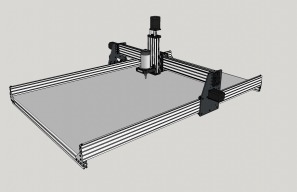

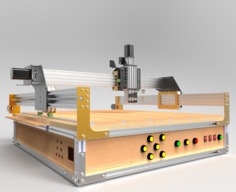

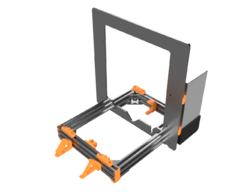

Something a Tad different

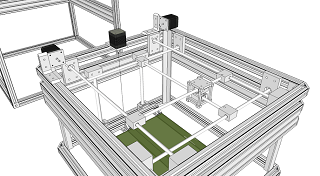

Future CNC router kit design

Build Author

Limine3D

Views

4781

Build Author

Limine3D

Views

4781

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

obmilllivebuild

Views

5771

Build Author

obmilllivebuild

Views

5771

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

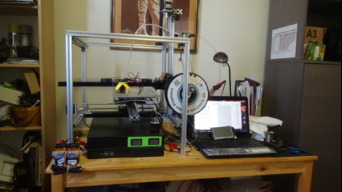

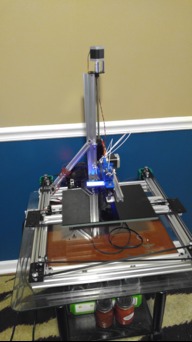

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

TimVukman

Views

4422

Build Author

TimVukman

Views

4422

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

Jose A. Molina

Views

7051

Build Author

Jose A. Molina

Views

7051

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Build Author

ymilord

Views

22413

Build Author

ymilord

Views

22413

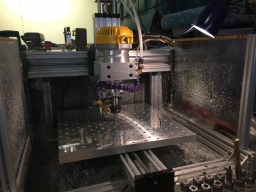

C-Beam Rigid - 'The Hog'

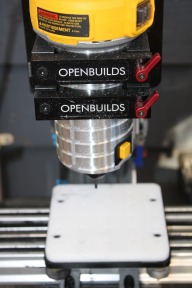

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

hbtousa

Views

3419

Build Author

hbtousa

Views

3419

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

OffAxis

Views

7963

Build Author

OffAxis

Views

7963

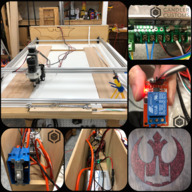

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

crnrstndes

Views

4371

Build Author

crnrstndes

Views

4371

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

spark2

Views

5881

Build Author

spark2

Views

5881

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

Huub65

Views

9524

Build Author

Huub65

Views

9524

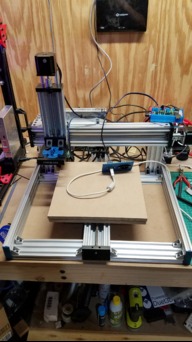

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

bpatterson42

Views

3709

Build Author

bpatterson42

Views

3709

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

pek

Views

27354

Build Author

pek

Views

27354

Prusa i3 Bear Half Upgrade v1.0

Stronger frame for Prusa i3 MK2 / MK2s / MK2.5 3D printer

Build Author

Camvec

Views

6410

Build Author

Camvec

Views

6410

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Build Author

dmasters

Views

8377

Build Author

dmasters

Views

8377

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Build Author

Carl van Heezik

Views

8681

Build Author

Carl van Heezik

Views

8681

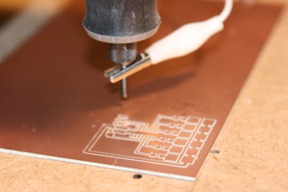

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

Teflon4

Views

16091

Build Author

Teflon4

Views

16091

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

CandlerCustoms

Views

5767

Build Author

CandlerCustoms

Views

5767

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

Ronald van Arkel

Views

16826

Build Author

Ronald van Arkel

Views

16826

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

Tucstrlly

Views

9251

Build Author

Tucstrlly

Views

9251

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

Terone Burgenheim

Views

6621

Build Author

Terone Burgenheim

Views

6621

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Terone Burgenheim

Views

2900

Build Author

Terone Burgenheim

Views

2900

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

patdee

Views

5267

Build Author

patdee

Views

5267

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

jamesdjadams

Views

12408

Build Author

jamesdjadams

Views

12408

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

DaveStewart

Views

6296

Build Author

DaveStewart

Views

6296

Small C-Beam Plate Maker With Remote Login & Operation

C-Beam Plate cutter with Raspberry Pi V3, Arduino Mega2560 and Camera. Remote login & operation via SSH with cnc.js server, mjpg server on the Pi.

Build Author

Kyo

Views

10399

Build Author

Kyo

Views

10399

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

CubeSpawn

Views

19966

Build Author

CubeSpawn

Views

19966

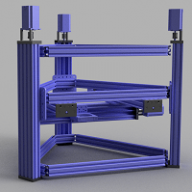

CubeSpawn Ultimaker 3D Printer Module

This 3D printer is an implementation of the Ultimaker 3D printer Using the Modular approach, many of the parts from the CubeSpawn 3 axis mill translate straight across into this design, so adding new concepts should go quicker

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

Anthony Castelluci

Views

3323

Build Author

Anthony Castelluci

Views

3323

Simple Camera Lofted Camera Slider

Build a manual camera slider.

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

Linear Rail derivative with ball screw

basic start to design of cnc machine

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Build Author

Hisha

Views

8966

Build Author

Hisha

Views

8966

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

Build Author

Greg Lampman

Views

9371

Build Author

Greg Lampman

Views

9371

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

Build Author

THE LINK

Views

5185

Build Author

THE LINK

Views

5185

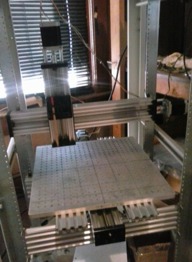

2020 First build.

Probably cheapest DIY build youl see.

Vertek CNC - 1000mm x 750mm Linear Rail on C Beam

C beam gantry with steel guide rails!

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

M^3

Views

22302

Build Author

M^3

Views

22302

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Robert Bailey

Views

29590

Build Author

Robert Bailey

Views

29590

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

Sonny Lowe

Views

7143

Build Author

Sonny Lowe

Views

7143

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

CNC Planning

Reusing parts to build a CNC - planning stage

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

MiniMill

Building a small mill to match my 7x12 lathe.

Build Author

Hisha

Views

5226

Build Author

Hisha

Views

5226

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

C-Beam based modular Resin Printer

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

Build Author

Steven Sampson

Views

11099

Build Author

Steven Sampson

Views

11099

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

mikev

Views

8747

Build Author

mikev

Views

8747

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Tomas F Uribe

Views

5465

Build Author

Tomas F Uribe

Views

5465

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

Thair.nl

Views

3950

Build Author

Thair.nl

Views

3950

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Limine3D

Views

21987

Build Author

Limine3D

Views

21987

M3Delta

Delta printer designed in sketchup and includes an adjustable bed.

Build Author

Rich Bowen

Views

3936

Build Author

Rich Bowen

Views

3936

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

Makerparts.ca Prusa i3Pro 300

Concept for a Prusa i3 made from Cbeam Extrusion. X & Y using GT2 Belts, Z using Acme Screws Goal is to build a simple. and very Solid Printer Single Z Motor to keep the Z Screws in Sync. (Might require Geared Nema 17) 12" x 12" x 12" Build volume Nema 17's

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

chenderson

Views

13022

Build Author

chenderson

Views

13022

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

blackcat3d printer

in construction ! chassis vslot 80x20 & 20x20 & 60x80 (Z) home made plates with whells polycarbonate build volume environ, 750x300x200 2 ed3d v6 volcano nozzles 0.8mm & 0.6 + titan extrudeurs rumba bord + auto levelling ip camera home made heat bed aluminium 5mm + glass + heat air chamber 6 doors plexiglass......

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

C-Beam bellows

Making a bellows to cover a C-beam to prevent swarf from gumming up the works.

plasma cnc

Homemade plasma cnc

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

Ken376

Views

3850

Build Author

Ken376

Views

3850

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Build Author

Maxime Favre

Views

9627

Build Author

Maxime Favre

Views

9627

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

All in One Grill -Mangal Schaschlik Döner

I create for some Years this all in one Grill. This Grill is without wellding, only fixed with screws. My Grill is 5 years old and look so, as at the first day (no moving away). The drawings and discription (sorry only in German, but with some pictures) to Download as PDF file. The unwindings to Download as DXF and GEO (Trumpf Laser) file. Have fun to build and Grill

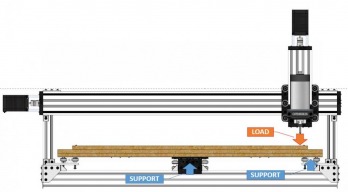

CNC Glass Grinder

This is a 1-Axis CNC Glass Grinder. It uses a hobby grinder to miter a precise angle on the edge of a piece of glass.

Build Author

Tim Pierce

Views

14619

Build Author

Tim Pierce

Views

14619

Openbuilds V slot Rail extrusion retrofits for Lulzbot 4/5 Taz Printers (X, Y and Z axis)

This project shows how to use Openbuilds Vv slot extrusions and wheels to retrofit a Lulzbot Taz 4 or 5 printer. These modifications improve layer consistency, eliminate nozzle and bed sag, and allow for larger toolhead mounting. Project updates and newer accessory files may be located at http://www.thingiverse.com/piercet/designs

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.