Build List

-

Active Filters:

h

Build Author

Robert Mech

Views

10102

Build Author

Robert Mech

Views

10102

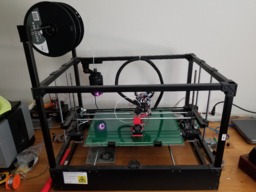

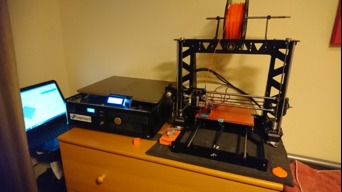

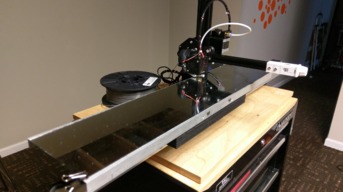

LayerFused C201 - DIY 3D Printer Build, i3 Style

My DIY 3D Printer build which is similar to an i3 style printer. This is a fully documented step-by-step build with videos.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

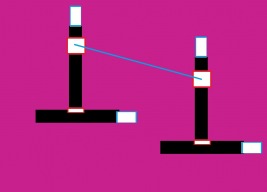

Two color Drawmachine

GRBL, vvvv, drawbot, penchanger, custom plates

Build Author

megashub

Views

24558

Build Author

megashub

Views

24558

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Mark Carew

Views

93538

Build Author

Mark Carew

Views

93538

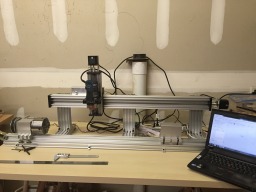

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

Build Author

tmadrms

Views

7919

Build Author

tmadrms

Views

7919

C-Beam Mods

C-beam machine mods.

Build Author

RobSaunders

Views

17304

Build Author

RobSaunders

Views

17304

Laser Cutter/Engraver OptLaser 6W with Z-axis

This was my first attempt for a laser platform. I'm using the OpenBuilds ACRO 20"x40 platform, 6W OptLaser, homemade z height and the xPro driver board.

Build Author

Mark Carew

Views

28567

Build Author

Mark Carew

Views

28567

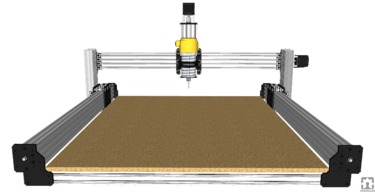

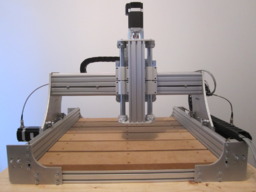

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Build Author

j0achim

Views

12456

Build Author

j0achim

Views

12456

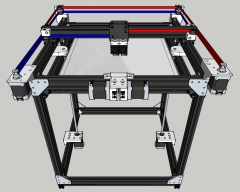

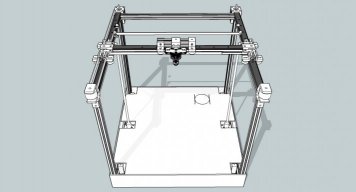

CoreXY - e3d inspired

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Build Author

Craig Hollabaugh

Views

5042

Build Author

Craig Hollabaugh

Views

5042

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

mjenkins5720

Views

3037

Build Author

mjenkins5720

Views

3037

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

Build Author

recoush

Views

9496

Build Author

recoush

Views

9496

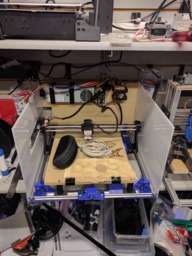

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Cortellini

Views

4623

Build Author

Cortellini

Views

4623

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

Build Author

taratata2016

Views

8790

Build Author

taratata2016

Views

8790

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Lasersc

Views

10560

Build Author

Lasersc

Views

10560

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

viktop

Views

18965

Build Author

viktop

Views

18965

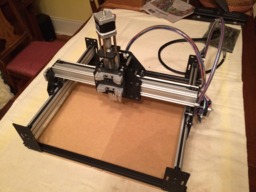

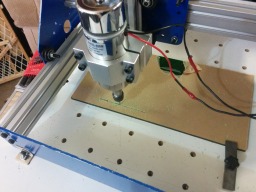

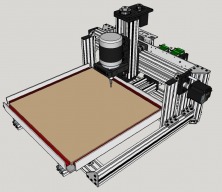

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

H-Bot CoreXY Cube

Dead build.

Build Author

Lasersc

Views

5633

Build Author

Lasersc

Views

5633

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Build Author

James Evanko

Views

7501

Build Author

James Evanko

Views

7501

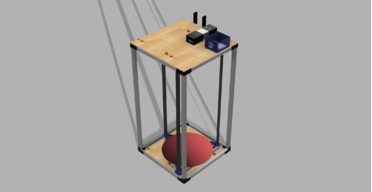

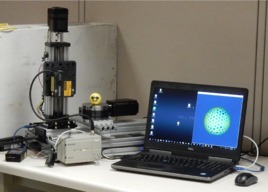

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Openbuilds C-beam

This is a build supported by Ooznest by a team of girls in Year 8 (12/13 years old) to machine model F1 cars for the F1 in Schools competition.

Build Author

pek

Views

84999

Build Author

pek

Views

84999

Prusa i3 Bear Upgrade V2

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Build Author

roadss

Views

26225

Build Author

roadss

Views

26225

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

msdosfx

Views

6286

Build Author

msdosfx

Views

6286

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

C Beam Rotary

I've used the good work of Openbuilds & expanded it to suit.

Build Author

RobFromLDMS

Views

5404

Build Author

RobFromLDMS

Views

5404

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Rotary CNC

I'm building a machine specifically for doing 4th axis work on woodwind instruments.

Build Author

RV6APilot

Views

4302

Build Author

RV6APilot

Views

4302

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

Stan Howe

Views

3436

Build Author

Stan Howe

Views

3436

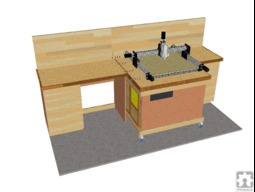

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

John J Talavera

Views

18826

Build Author

John J Talavera

Views

18826

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Taller couch legs

A simple but elegent couch legs

Build Author

Mark Carew

Views

36892

Build Author

Mark Carew

Views

36892

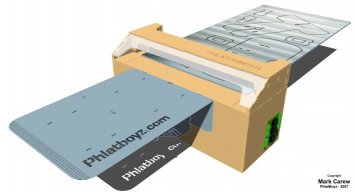

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

Build Author

Mark Carew

Views

75957

Build Author

Mark Carew

Views

75957

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

GhettoPrinter

Dirt cheap build.

Build Author

Cortellini

Views

5735

Build Author

Cortellini

Views

5735

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

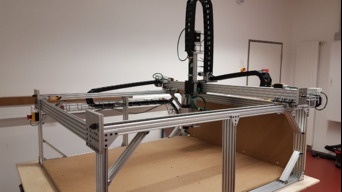

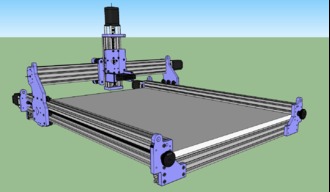

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

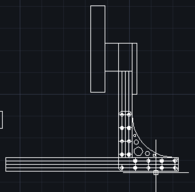

CNC Hot Wire Cutter 4 Axis for Cutting Foam Wings

My build is to allow me to cut foam wings using CNC Hot Wire Cutter.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

Spark Concepts

Views

5522

Build Author

Spark Concepts

Views

5522

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

SMD Pick and place machine - Smoothieboard/OpenPnp

A dual head PNP machine that uses Openbuilds hardware, a Smoothieboard controller, dual camera vision, automatic/drag feeders, and OpenPnp.

Build Author

JerwanDavis

Views

6214

Build Author

JerwanDavis

Views

6214

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

thinman

Views

8952

Build Author

thinman

Views

8952

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

Build Author

Cosmosteel

Views

4689

Build Author

Cosmosteel

Views

4689

Clear Acrylic Dust Shoe

Attaches router with screw clamping. Clear Skirt is 2" long or can be made longer if requested. Works well keeping dust within the chamber. It can be made to fit shapeoko, ox cnc, workbee, xcarve, 6040, laguna,piranha, millright etc. with similar setup including Bosh, Makita , dewalt 611 routers or spindles.

Build Author

CharlieShimota

Views

16377

Build Author

CharlieShimota

Views

16377

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

Build Author

Hidro669

Views

3867

Build Author

Hidro669

Views

3867

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Build Author

Metalguru

Views

14921

Build Author

Metalguru

Views

14921

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Build Author

Christian James

Views

10302

Build Author

Christian James

Views

10302

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Joe Young

Views

6054

Build Author

Joe Young

Views

6054

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

Build Author

pedrofernandez

Views

15430

Build Author

pedrofernandez

Views

15430

The Franken Forty

This is a K40 machine conversion!!

Build Author

Jacob Lotter

Views

6182

Build Author

Jacob Lotter

Views

6182

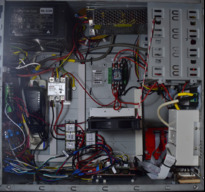

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Build Author

joetemus

Views

7022

Build Author

joetemus

Views

7022

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

Rob Taylor

Views

20697

Build Author

Rob Taylor

Views

20697

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

David Hartkop

Views

3129

Build Author

David Hartkop

Views

3129

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

Build Author

pedrofernandez

Views

10147

Build Author

pedrofernandez

Views

10147

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Build Author

Savvas

Views

19043

Build Author

Savvas

Views

19043

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

Build Author

Eric Jacobsson

Views

15654

Build Author

Eric Jacobsson

Views

15654

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

Connor Mckeown

Views

6540

Build Author

Connor Mckeown

Views

6540

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Rob Mahan

Views

14109

Build Author

Rob Mahan

Views

14109

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

CNC by MagicMarcus

CNC variation about Sphinx.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

My Shapeoko Router build

I built this as it is a small portable design.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

ChrisViral

Views

7306

Build Author

ChrisViral

Views

7306

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

James Evanko

Views

4211

Build Author

James Evanko

Views

4211

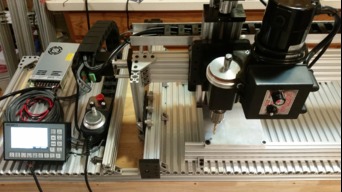

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

Rick Holder

Views

15546

Build Author

Rick Holder

Views

15546

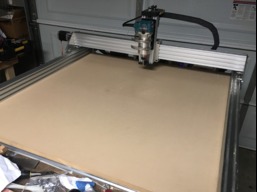

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

Luke Cunningham

Views

5981

Build Author

Luke Cunningham

Views

5981

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

SCYBUCK

Views

5207

Build Author

SCYBUCK

Views

5207

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Michael.M

Views

9816

Build Author

Michael.M

Views

9816

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

Jones

Views

4092

Build Author

Jones

Views

4092

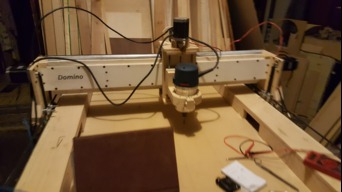

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

My Little Mashup

A mixed drive, PI Controlled machine

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

Build Author

Nicademus

Views

9823

Build Author

Nicademus

Views

9823

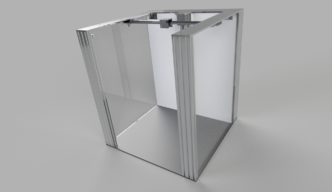

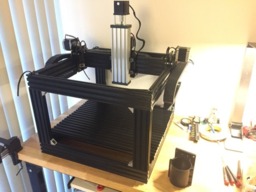

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

stepper

Views

4657

Build Author

stepper

Views

4657

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

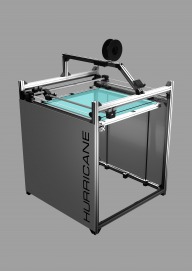

Hurricane - Large 80cm x 80cm x 80cm cm build space project

Huge - Fast - Affordable

Build Author

Carl Siren

Views

7763

Build Author

Carl Siren

Views

7763

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

thehans

Views

6804

Build Author

thehans

Views

6804

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

pedrofernandez

Views

12294

Build Author

pedrofernandez

Views

12294

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Gary Caruso

Views

25091

Build Author

Gary Caruso

Views

25091

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z