Build List

-

Active Filters:

m

Build Author

Karan Singh Sisodia

Views

6491

Build Author

Karan Singh Sisodia

Views

6491

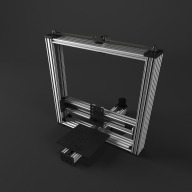

My Home made CNC

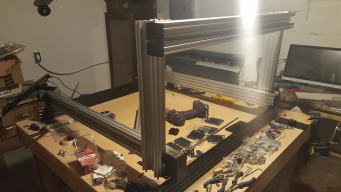

Home Made CNC Router from Scrape

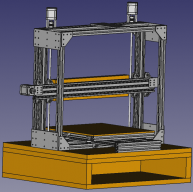

Steel Frame CNC Router

A scratch built steel frame CNC Router.

DIY LED acrylic lamp

This is a simple lamp using only 2 LEDs & 2 AAA batteries.

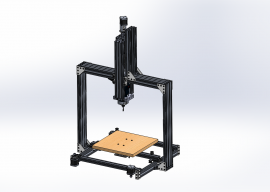

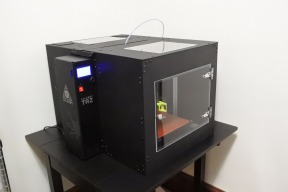

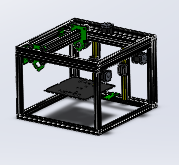

Steel Frame 3D Printer

A steel framed 3D printer using a similar design with my CNC Router.

Build Author

Sonny Lowe

Views

7185

Build Author

Sonny Lowe

Views

7185

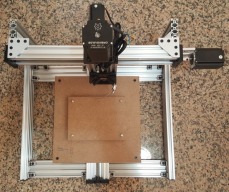

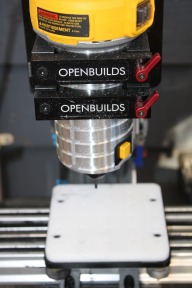

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

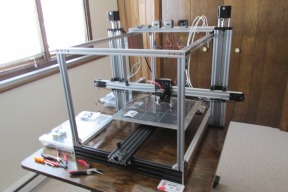

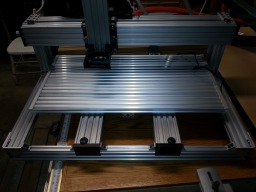

CNC Planning

Reusing parts to build a CNC - planning stage

Build Author

Venturebit

Views

14273

Build Author

Venturebit

Views

14273

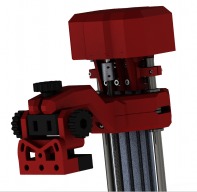

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

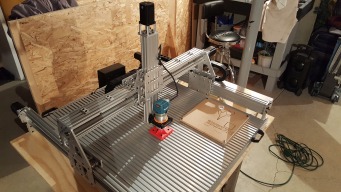

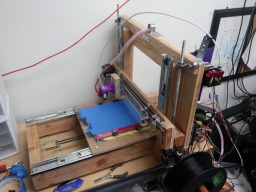

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

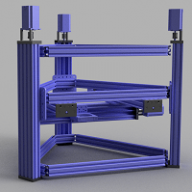

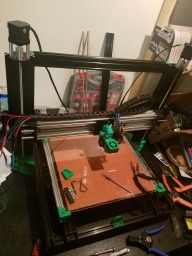

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Build Author

Fabio Orsi

Views

7090

Build Author

Fabio Orsi

Views

7090

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

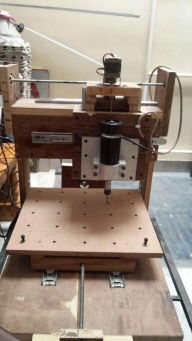

MiniMill

Building a small mill to match my 7x12 lathe.

Build Author

mirage335

Views

7504

Build Author

mirage335

Views

7504

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Build Author

evgeny156

Views

7484

Build Author

evgeny156

Views

7484

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Hisha

Views

5240

Build Author

Hisha

Views

5240

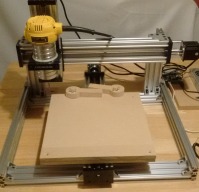

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

Limine3D

Views

8777

Build Author

Limine3D

Views

8777

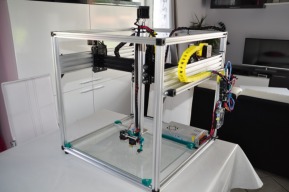

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Anglesachse

Views

29430

Build Author

Anglesachse

Views

29430

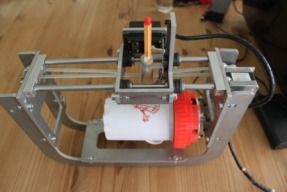

Pot Plotter

My version of the Mug Plotter designed by Teed http://edinburghhacklab.com/ . Also used the Eibotboard from the original eggbot from evilmadscientists http://shop.evilmadscientist.com/partsmenu/188-ebb A huge thanks to Hexitex for his brilliant Four jaw chuck http://www.thingiverse.com/thing:5791

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

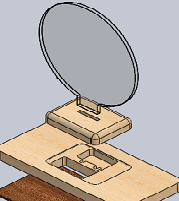

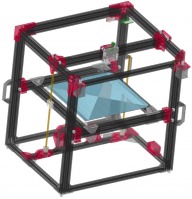

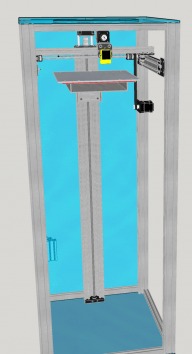

C-Beam based modular Resin Printer

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

Build Author

Steven Sampson

Views

11127

Build Author

Steven Sampson

Views

11127

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

mikev

Views

8784

Build Author

mikev

Views

8784

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Tomas F Uribe

Views

5478

Build Author

Tomas F Uribe

Views

5478

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Build Author

J-Wahl Dezign

Views

9284

Build Author

J-Wahl Dezign

Views

9284

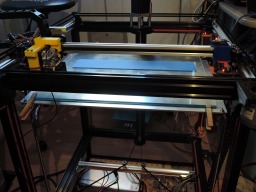

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

Thair.nl

Views

3975

Build Author

Thair.nl

Views

3975

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Build Author

nschreiber0813

Views

5663

Build Author

nschreiber0813

Views

5663

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

Build Author

adamcooks

Views

43615

Build Author

adamcooks

Views

43615

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Jonathon Duerig

Views

7379

Build Author

Jonathon Duerig

Views

7379

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

Limine3D

Views

22029

Build Author

Limine3D

Views

22029

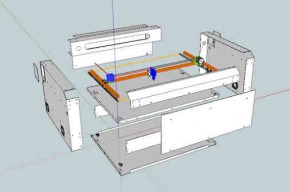

M3Delta

Delta printer designed in sketchup and includes an adjustable bed.

Suitcase Vacuumformer

Quick overview of my build up for a vacuum former that is self contained, portable and fairly easy to build.

Build Author

Peter Van Der Walt

Views

7738

Build Author

Peter Van Der Walt

Views

7738

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

Rich Bowen

Views

3955

Build Author

Rich Bowen

Views

3955

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

Makerparts.ca Prusa i3Pro 300

Concept for a Prusa i3 made from Cbeam Extrusion. X & Y using GT2 Belts, Z using Acme Screws Goal is to build a simple. and very Solid Printer Single Z Motor to keep the Z Screws in Sync. (Might require Geared Nema 17) 12" x 12" x 12" Build volume Nema 17's

Build Author

Matt Barile

Views

7800

Build Author

Matt Barile

Views

7800

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

Robert Hummel

Views

25855

Build Author

Robert Hummel

Views

25855

Stinger V Micro Mill

While building my OX AI I found myself with left over v slot and thought to myself, what do I need that I can build using them? Well since I make a lot of my own PCB boards for projects I figured a micro PCB mill would fit the bill ;) With inspiration from the OX and OX AI I give you the Stinger V :)

Build Author

3D Meister

Views

5737

Build Author

3D Meister

Views

5737

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

Robert Huxford

Views

4172

Build Author

Robert Huxford

Views

4172

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

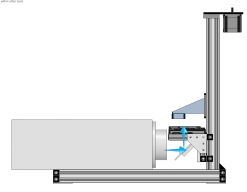

Touchsensor assembly machine

This is a handy machine to assemble touch sensors into display frame.

Build Author

Dmknerr

Views

5337

Build Author

Dmknerr

Views

5337

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

Anthony Bolgar

Views

12276

Build Author

Anthony Bolgar

Views

12276

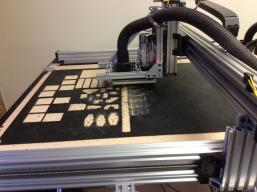

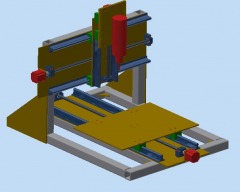

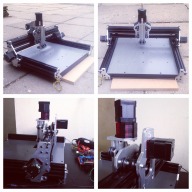

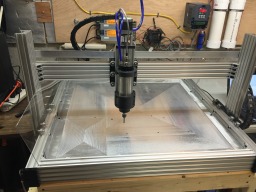

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

Build Author

Anthony Bolgar

Views

5864

Build Author

Anthony Bolgar

Views

5864

Air assist/fume collector for Diode Laser Engraver

This is a work in progress

Build Author

chenderson

Views

13057

Build Author

chenderson

Views

13057

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

Build Author

DistortedDesigns

Views

34394

Build Author

DistortedDesigns

Views

34394

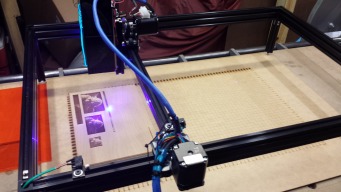

Project Death Star - DistortedDesigns Laser Engraver

2 watt Laser Engraver, Simple, Fairly Low Cost, and Portable

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

Build Author

Ronald van Arkel

Views

33757

Build Author

Ronald van Arkel

Views

33757

Routy GT2 290 BSX CNC Router, Low Cost and Good!

The Routy GT2 300 BSX CNC Router is a Low Cost CNC build. It performs the same as the larger Routy's from OpenBuilds but doesn't break the bank!

KALΔIS OPEN SLA

Modular easy to adjust scale of the entire build Tablet/LCD monitor SLA 3d Printer.

Build Author

Keteland

Views

10854

Build Author

Keteland

Views

10854

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Makerparts

Views

7881

Build Author

Makerparts

Views

7881

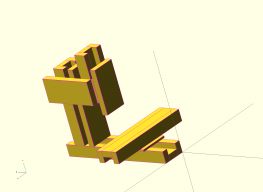

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

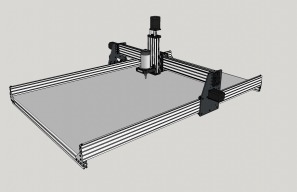

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

Build Author

Linkreincarnate

Views

3225

Build Author

Linkreincarnate

Views

3225

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Build Author

TouchPadKing

Views

5212

Build Author

TouchPadKing

Views

5212

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

dodgenet

Views

6779

Build Author

dodgenet

Views

6779

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

plasma cnc

Homemade plasma cnc

Build Author

openhardwarecoza

Views

28921

Build Author

openhardwarecoza

Views

28921

openBuilds FreeBURN-2-Mini V-slot CO2 Laser (40-50w)

A new mini version of the http://openbuilds.com/builds/openbuilds-freeburn-1-v-slot-co2-laser-60-100w.1001/ FreeBurn CO2 Lasercutter

Build Author

Hytech2k

Views

34218

Build Author

Hytech2k

Views

34218

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

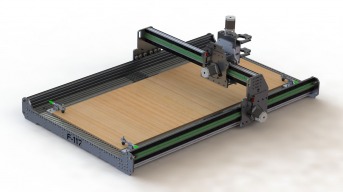

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Build Author

Steve B

Views

15882

Build Author

Steve B

Views

15882

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

Ken376

Views

3866

Build Author

Ken376

Views

3866

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Linear Rail for Dobot Magician

This is a simpel build of a Linear rail for the Dobot Magician.

Build Author

Larry_AK

Views

10383

Build Author

Larry_AK

Views

10383

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

Joe Garritano

Views

11968

Build Author

Joe Garritano

Views

11968

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

Build Author

Jose A. Molina

Views

7166

Build Author

Jose A. Molina

Views

7166

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Edgar Robles

Views

4195

Build Author

Edgar Robles

Views

4195

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Philippe Bergeron

Views

10262

Build Author

Philippe Bergeron

Views

10262

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

Build Author

Maxime Favre

Views

9648

Build Author

Maxime Favre

Views

9648

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

CNC Glass Grinder

This is a 1-Axis CNC Glass Grinder. It uses a hobby grinder to miter a precise angle on the edge of a piece of glass.

Build Author

mytechno3d

Views

66538

Build Author

mytechno3d

Views

66538

Maximus 3D Printer

A full scalable 3D Printer , with a big printing area. Build with openbuild parts from www.vslot-europe.com

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

Rob Taylor

Views

26851

Build Author

Rob Taylor

Views

26851

DSLR Video Slider

A simple 1500mm V Slot camera slider for timelapse and possibly video with an Arduino Uno controlling a Pololu A4988 driving an OpenBuilds NEMA 17 stepper, and triggering the camera.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Build Author

AK-Creation

Views

15170

Build Author

AK-Creation

Views

15170

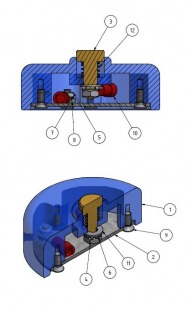

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Schematix OX metal build

OX metal build from an noob