CNC ROUTER BUILDS

Build Author

TurfnSurf

Views

7112

Build Author

TurfnSurf

Views

7112

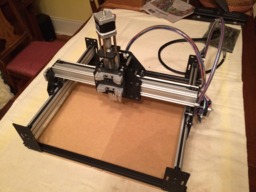

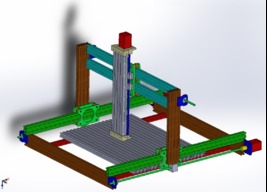

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

spark2

Views

5670

Build Author

spark2

Views

5670

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Sprags

Views

2727

Build Author

Sprags

Views

2727

C-Beam Kyo Sphinx 10060

More stuff here.

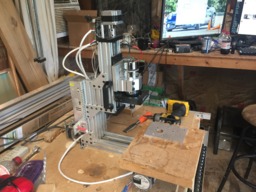

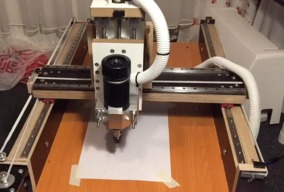

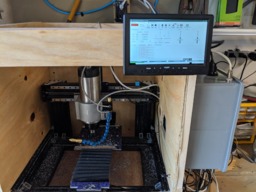

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

jz321

Views

4551

Build Author

jz321

Views

4551

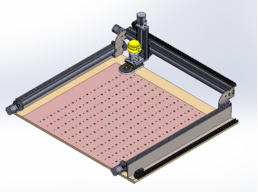

OTiS 500mm

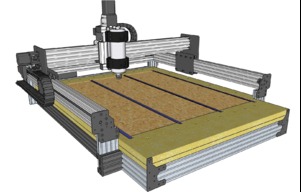

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

crnrstndes

Views

4207

Build Author

crnrstndes

Views

4207

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

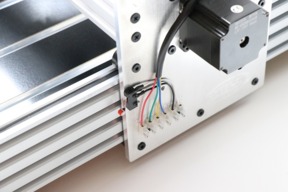

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

Bucky Wootmaster

Views

2981

Build Author

Bucky Wootmaster

Views

2981

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Build Author

obmilllivebuild

Views

5627

Build Author

obmilllivebuild

Views

5627

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Build Author

Limine3D

Views

4512

Build Author

Limine3D

Views

4512

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

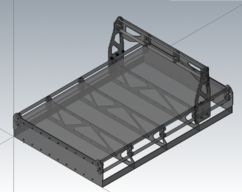

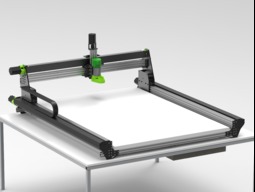

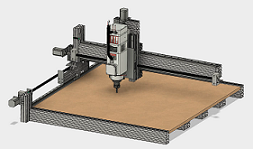

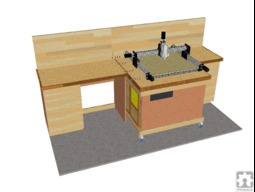

Something a Tad different

Future CNC router kit design

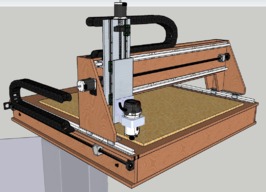

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

Axnfell

Views

3070

Build Author

Axnfell

Views

3070

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

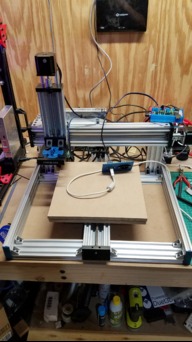

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Build Author

Kevr102

Views

5814

Build Author

Kevr102

Views

5814

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Hussein Dermay

Views

6471

Build Author

Hussein Dermay

Views

6471

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

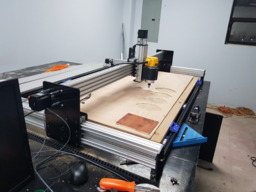

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Build Author

Brandon Satterfield

Views

7698

Build Author

Brandon Satterfield

Views

7698

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Big-X Minimill

Minimill bundle, but with an extended X Axis

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

ChrisViral

Views

7124

Build Author

ChrisViral

Views

7124

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

reef

Views

11945

Build Author

reef

Views

11945

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Andreas Bockert

Views

11957

Build Author

Andreas Bockert

Views

11957

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

SCYBUCK

Views

5118

Build Author

SCYBUCK

Views

5118

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Jones

Views

3971

Build Author

Jones

Views

3971

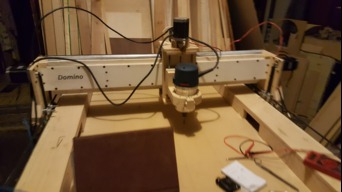

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

My Little Mashup

A mixed drive, PI Controlled machine

Build Author

Rob Taylor

Views

10904

Build Author

Rob Taylor

Views

10904

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Router for speargun hobby

First router build for speargun fabrication

Build Author

C-CNC

Views

16119

Build Author

C-CNC

Views

16119

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Phil's MiniMill

A quick little mini mill build

CNC by MagicMarcus

CNC variation about Sphinx.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Build Author

Kyo

Views

45618

Build Author

Kyo

Views

45618

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

RobFromLDMS

Views

5216

Build Author

RobFromLDMS

Views

5216

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

joetemus

Views

6815

Build Author

joetemus

Views

6815

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Build Author

Craig Hollabaugh

Views

4844

Build Author

Craig Hollabaugh

Views

4844

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Vin1027

Views

7317

Build Author

Vin1027

Views

7317

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Build Author

Bikes and Beer

Views

4836

Build Author

Bikes and Beer

Views

4836

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Troy Proffitt

Views

28916

Build Author

Troy Proffitt

Views

28916

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

Build Author

Christian James

Views

9898

Build Author

Christian James

Views

9898

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

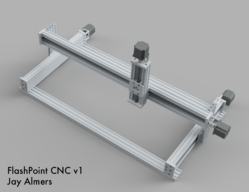

Build Author

Jay Almers

Views

7997

Build Author

Jay Almers

Views

7997

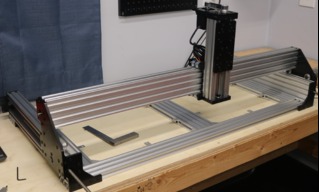

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Cortellini

Views

5572

Build Author

Cortellini

Views

5572

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Doug Rowley

Views

4333

Build Author

Doug Rowley

Views

4333

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

msdosfx

Views

6143

Build Author

msdosfx

Views

6143

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

OoozNest WorkBee

A Journey on the WorkBee Build...

Build Author

Stan Howe

Views

3315

Build Author

Stan Howe

Views

3315

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

My Workbee build

Workbee, 1000mmX750mm , from China

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

My build

I am satisfied with my build and next one will be even better.

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

RV6APilot

Views

4222

Build Author

RV6APilot

Views

4222

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

KronBjorn

Views

4454

Build Author

KronBjorn

Views

4454

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

75x75

Simple cnc with 5mm steel plates.

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

CNC Router Machine

CNC Router with working area 550*550*200

Build Author

Project Hopeless

Views

14436

Build Author

Project Hopeless

Views

14436

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

BKE Lead 1010 - First CNC Router

LEAD CNC

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

Build Author

Marco964

Views

8989

Build Author

Marco964

Views

8989

Lead CNC 1510 modified

This is an Openbuilds LEAD 1510, modified to supports a liquid cooled 1.5Kw spindle. The movements are made with lead screw on all three axes.

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Build Author

tmadrms

Views

7680

Build Author

tmadrms

Views

7680

C-Beam Mods

C-beam machine mods.

Build Author

Joe F

Views

8462

Build Author

Joe F

Views

8462

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

Neil Scott

Views

3235

Build Author

Neil Scott

Views

3235

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

Workbee 1010

Hey all looking forward to sharing this build, I’ve learned a lot reviewing many of these great builds.