Build List

Build Author

SlyClockWerkz

Views

17099

Build Author

SlyClockWerkz

Views

17099

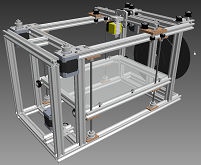

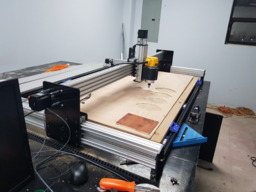

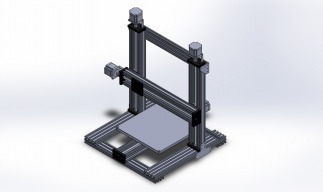

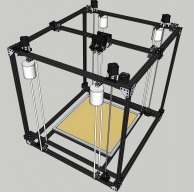

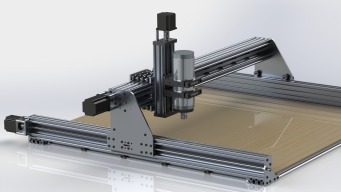

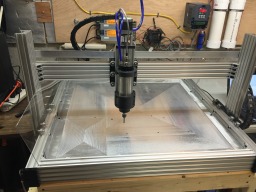

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

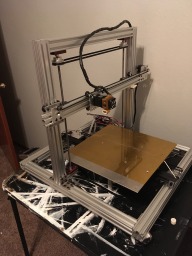

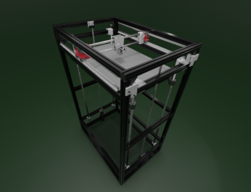

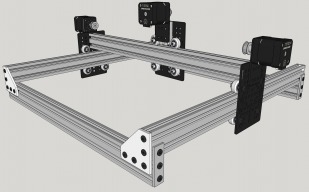

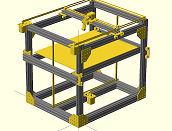

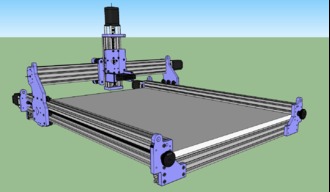

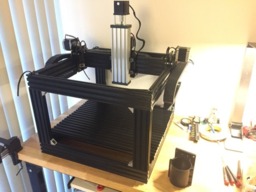

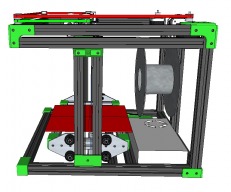

OKMI 3d Printer

OKMI 3d Printer based on CoreXY

Build Author

Steve B

Views

15884

Build Author

Steve B

Views

15884

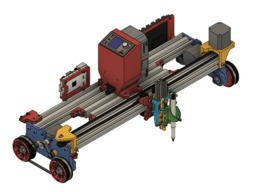

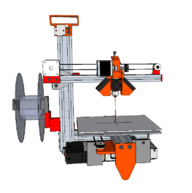

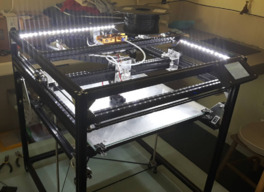

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

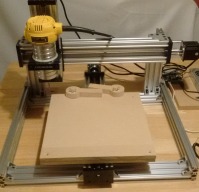

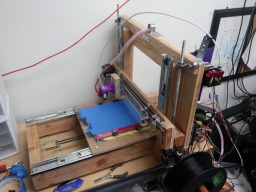

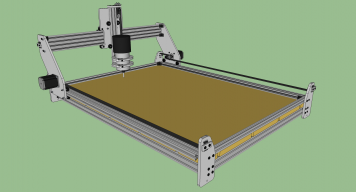

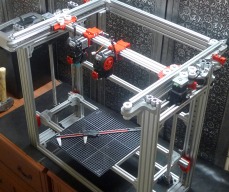

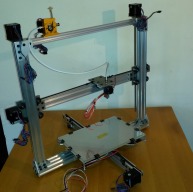

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Build Author

ymilord

Views

22440

Build Author

ymilord

Views

22440

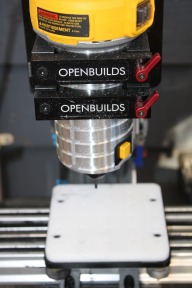

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

Rob Taylor

Views

21025

Build Author

Rob Taylor

Views

21025

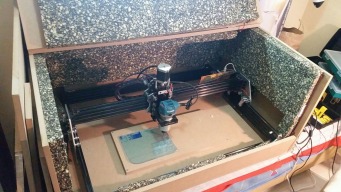

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

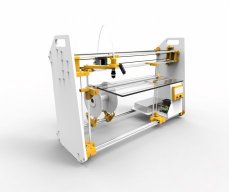

Pelican Case 3D Printer

A portable 3D Printer that can flat pack into a hard carry case

My 1st Build - Delta Printer with 3 filament hot end

The build area will be fully enclosed. I anticipate using primarily ABS, and have interest in the soluble support materials as well. The main components to date include: OPENBUILDS - 3 x C-Beam™ Linear Actuator Bundle, 1000 mm, w/ Included NEMA23 Motor) Extruders (3) - [Sintron] 1.75mm Mini All Metal MK8 Extruder Hot End - reprap diamond Control board - RUMBA Stepper drivers - DRV8825 StepStick Power supply - eTopxizu 12v 30a

Build Author

ymilord

Views

12902

Build Author

ymilord

Views

12902

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

Bridge Port

Views

9582

Build Author

Bridge Port

Views

9582

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Laser engraving machine

Second better project, high durable mainframe, silent work, non vibration.

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Kyo

Views

16506

Build Author

Kyo

Views

16506

Stinger Laser

3-Axis CNC Laser Engraver running grbl 1.1 in laser mode and Laserweb4.

Kool Bot

Mid range build.

Build Author

Apothus

Views

22707

Build Author

Apothus

Views

22707

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

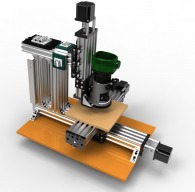

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

TrueUp Bold

A beefed up modification of the TrueUp Kit project

Build Author

Superslinky

Views

10574

Build Author

Superslinky

Views

10574

K40 Laser Build (Major Changes)

Major K40 Laser Mod

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

Build Author

CharlieShimota

Views

16465

Build Author

CharlieShimota

Views

16465

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

C_Beam Hammerhead 5x

setup for learning 5x

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Andreas Bockert

Views

12294

Build Author

Andreas Bockert

Views

12294

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

Spark Concepts

Views

5591

Build Author

Spark Concepts

Views

5591

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

Build Author

crypt-tek

Views

10243

Build Author

crypt-tek

Views

10243

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

KeePrint Monster

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

A Rolling Plotter

To build a simple plotter that rolls along the length of large paper, foam core or other flat objects.

Build Author

Sergio Di Ventura

Views

9558

Build Author

Sergio Di Ventura

Views

9558

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

2SIsurf

Views

6843

Build Author

2SIsurf

Views

6843

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

SailingBuild

Views

10549

Build Author

SailingBuild

Views

10549

5 x 10 CNC - Sub $3000 - Wall Mountable

I wanted a 5 x 10, Wall mounted CNC, that cost less than $3000. I think Im pretty close.

Build Author

AK-Creation

Views

22827

Build Author

AK-Creation

Views

22827

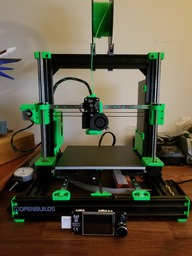

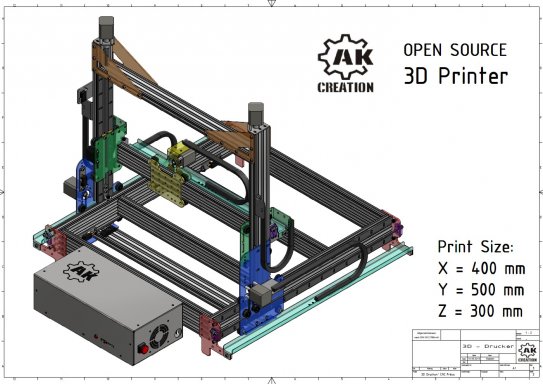

3D Printer - Big Size

I creat a open source 3D Printer to print big things. Print size: 400x500x300 mm. You can download the Drawing in PDF and in Inventor 2013 format. The unwinding drawings are also included. I take some detail photos for a better understanding.

Suitcase Vacuumformer

Quick overview of my build up for a vacuum former that is self contained, portable and fairly easy to build.

Build Author

pdesigns

Views

29232

Build Author

pdesigns

Views

29232

RepRap Tuga

This is a work in progress(not printing yet). Expect this instructions to grow with time, but for now it is mainly interesting for those who want to take part in developing this printer.

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

Build Author

Sheepdog

Views

27078

Build Author

Sheepdog

Views

27078

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

plasma cnc

Homemade plasma cnc

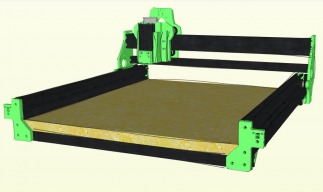

Small Red OX

A small router for thin plate stock

Build Author

M^3

Views

22345

Build Author

M^3

Views

22345

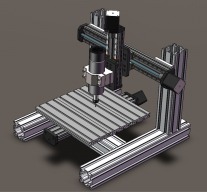

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

Build Author

Hytech2k

Views

34223

Build Author

Hytech2k

Views

34223

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

Build Author

Yoshiya Arii

Views

42485

Build Author

Yoshiya Arii

Views

42485

V-Slot Laser cutter and engraver

The Smart Laser Mini is an open source such as use Raspberry pi. Easy to assemble type of desktop laser cutter and engraver. Also we used V-slot

BAFP 3D Printer

A New Core XY Printer build. BAFP stands for Big And Fast Printer. It will be awesome !!

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

James Archer

Views

14773

Build Author

James Archer

Views

14773

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Build Author

Sonny Lowe

Views

7189

Build Author

Sonny Lowe

Views

7189

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

Small Laser Engraver Concept

Low cost Laser Engraver build using all off-the-shelf components.

KALΔIS OPEN SLA

Modular easy to adjust scale of the entire build Tablet/LCD monitor SLA 3d Printer.

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

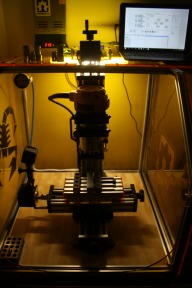

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

3D PrintBot 500x500x500

Large scale True 500x500x500 build volume 3D printer.

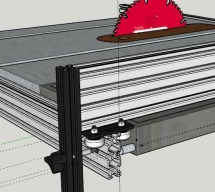

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

Build Author

chenderson

Views

13060

Build Author

chenderson

Views

13060

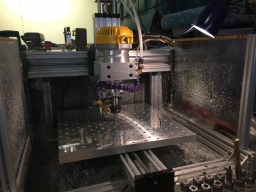

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

Build Author

pek

Views

6805

Build Author

pek

Views

6805

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

Build Author

Joerharris

Views

6707

Build Author

Joerharris

Views

6707

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Rob Mahan

Views

14355

Build Author

Rob Mahan

Views

14355

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Glenn Weston

Views

11792

Build Author

Glenn Weston

Views

11792

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Build Author

Tommy Williamson

Views

7415

Build Author

Tommy Williamson

Views

7415

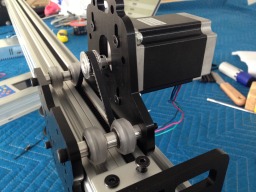

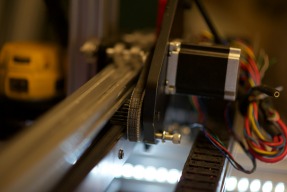

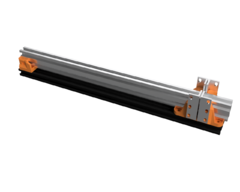

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Build Author

deltajegga

Views

10152

Build Author

deltajegga

Views

10152

THE delta

probably as big as you'd want it...

Build Author

Joe Young

Views

6149

Build Author

Joe Young

Views

6149

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

CoreCube3D

Views

22670

Build Author

CoreCube3D

Views

22670

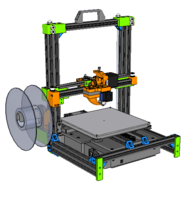

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

x_y_module laser engraver

low cost 2 axis cnc laser, really portable and easily expandable

Simpl3rBot

A framing design for cantilever style printers

Build Author

Jason Moore

Views

13502

Build Author

Jason Moore

Views

13502

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Build Author

Mark Carew

Views

93888

Build Author

Mark Carew

Views

93888

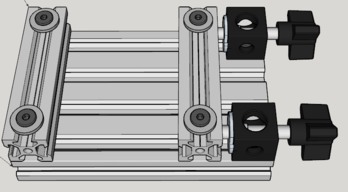

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

Tool position setting Part III.

In this, the final part, I would like to introduce Machine Vision and show how it can be used, not only for tool position setting but also for resolving the triangle to calculate the G68 (local system rotated) for jobs which are not squarely placed on the work table.

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

Build Author

Mark Carew

Views

66221

Build Author

Mark Carew

Views

66221

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Build Author

Rakmup

Views

41709

Build Author

Rakmup

Views

41709

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

Build Author

Keith Davis

Views

17897

Build Author

Keith Davis

Views

17897

OneZ

OneZ gets it's name from it's most unique feature - only motor for the Z axis while maintaining the stability of two bearing guides for the Z axis. Reduction to one Z motor eliminates need for auto bed leveling.

OX-Based Self-Contaned HVLP Spray Booth

A CNC HVLP spray booth based on OX.

Build Author

Keith Davis

Views

21072

Build Author

Keith Davis

Views

21072

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

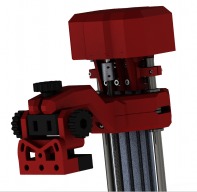

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

SCoreXY

Currently I have Velleman/3Drag K8200 modified and CNC machine self built and wanted to use both to make new 3D printer. After looking at different designs I liked Voron a lot and have decided to go that way. Currently I have ordered majority of parts and build shall start soon. I don't plan to rush it as I am usually 2 months home and 2 off. Today done some electronics. Looks ok. https://youtu.be/ls_tl54ruE0

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

2 GANTRY CNC HOTWIRE MACHINE

A 2 independent gantry affordable hotwire machine.

The Almost Perfect 3 Way Mitre (with MakerLinks)

A quick and easy way to make a 3-way mitered corner using MakerLinks

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

100w Laser Cutter Build Log

I rebuild my 2 meter tall 3D printer into a 100w laser cutter