Build List

-

Active Filters:

m

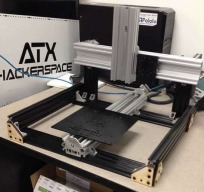

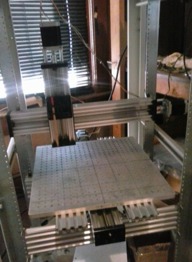

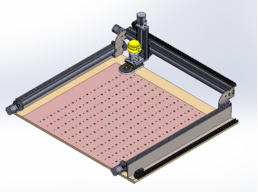

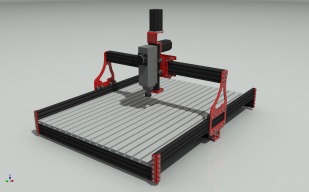

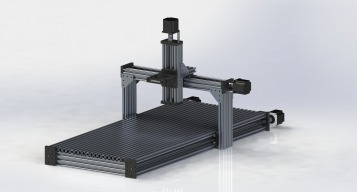

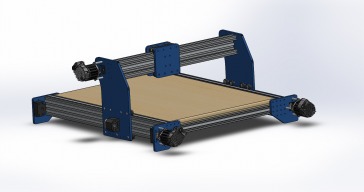

TABLE OX Router/3D-Printer

OX MultiMachine

Build Author

Pendragon

Views

10251

Build Author

Pendragon

Views

10251

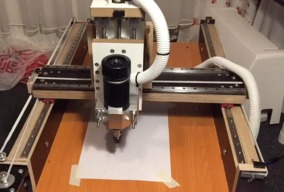

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

Build Author

Bear

Views

10906

Build Author

Bear

Views

10906

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

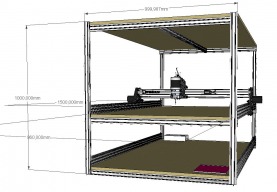

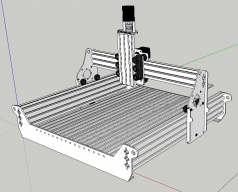

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

Pink Panther - MendelMax variant

Taller and wider MendelMax 1.5 spinoff

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

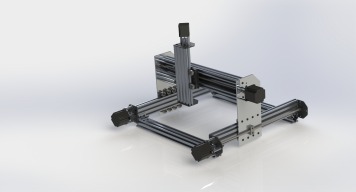

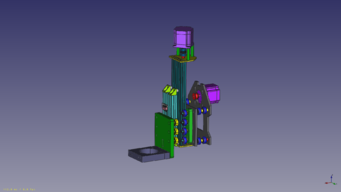

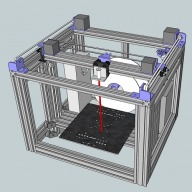

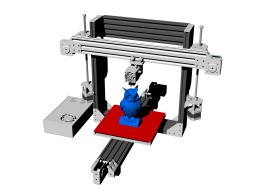

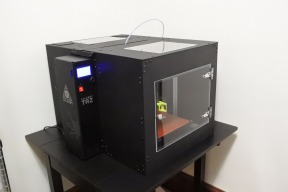

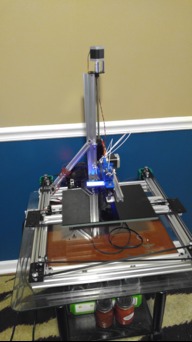

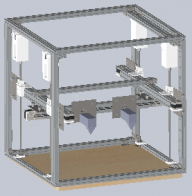

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Build Author

KBill

Views

13435

Build Author

KBill

Views

13435

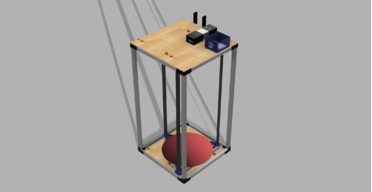

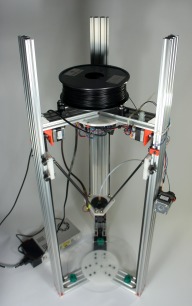

MIY OLY Delta Printer

Mag arm deltabot with laser cut carriages and connectors.

Build Author

Bruno Rivard

Views

6851

Build Author

Bruno Rivard

Views

6851

OB Heavy duty Prusa i3 "Lunar Injection"

Hell Yeah

Build Author

openhardwarecoza

Views

7075

Build Author

openhardwarecoza

Views

7075

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

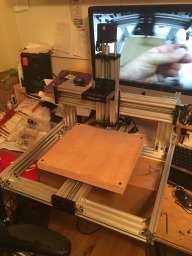

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Build Author

Skoobs

Views

4894

Build Author

Skoobs

Views

4894

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Build Author

Mark Carew

Views

9133

Build Author

Mark Carew

Views

9133

Work Bench Stand

Here is a nice little simple build that will help to free up some extra space on your work bench. If your like me you need all the room on your work station you can use, so this is great to have.

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

Nwrgordon

Views

15798

Build Author

Nwrgordon

Views

15798

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Build Author

evil2002usna

Views

11474

Build Author

evil2002usna

Views

11474

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

Sonny Lowe

Views

6015

Build Author

Sonny Lowe

Views

6015

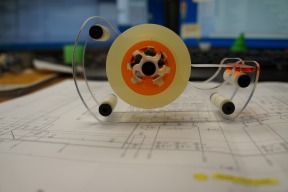

MakerSL MSL-7 Laser Cut Tape Dispenser

An easy simple Tape Dispenser, spawned out of necessity, and shared for the fun of it...

Build Author

Dave420

Views

6060

Build Author

Dave420

Views

6060

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

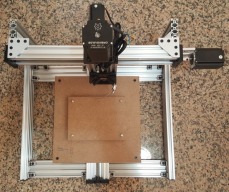

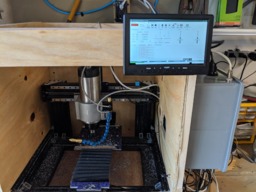

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

Build Author

dodgenet

Views

6509

Build Author

dodgenet

Views

6509

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Makerparts

Views

7618

Build Author

Makerparts

Views

7618

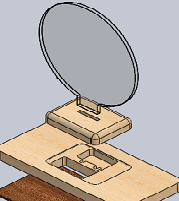

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Build Author

Dmknerr

Views

5134

Build Author

Dmknerr

Views

5134

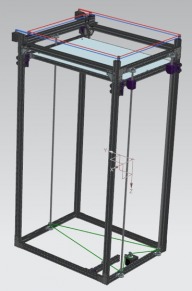

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

3D Meister

Views

5399

Build Author

3D Meister

Views

5399

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

DIY LED acrylic lamp

This is a simple lamp using only 2 LEDs & 2 AAA batteries.

Build Author

recoush

Views

9068

Build Author

recoush

Views

9068

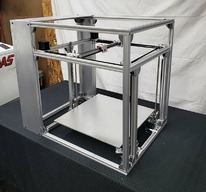

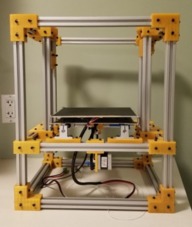

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jonathon Duerig

Views

7126

Build Author

Jonathon Duerig

Views

7126

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

Build Author

Tomas F Uribe

Views

5278

Build Author

Tomas F Uribe

Views

5278

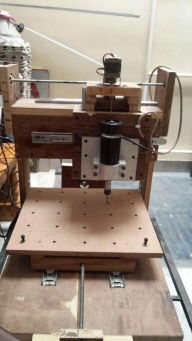

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

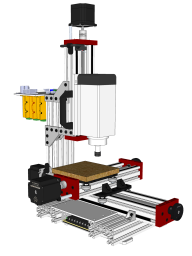

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Build Author

Karan Singh Sisodia

Views

6209

Build Author

Karan Singh Sisodia

Views

6209

My Home made CNC

Home Made CNC Router from Scrape

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

Build Author

Jason Harding

Views

4033

Build Author

Jason Harding

Views

4033

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

Build Author

Jeremiah Guinn

Views

5775

Build Author

Jeremiah Guinn

Views

5775

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

Ancient Roland Table top Mill

The parts are now very reasonable.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Ooznest workbee

This is my first build so I will let you know how I get on

Build Author

ZacharyB

Views

5652

Build Author

ZacharyB

Views

5652

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Terone Burgenheim

Views

2761

Build Author

Terone Burgenheim

Views

2761

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6337

Build Author

Terone Burgenheim

Views

6337

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Bill325

Views

2272

Build Author

Bill325

Views

2272

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

JAC_101

Views

5962

Build Author

JAC_101

Views

5962

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Build Author

Liam Dahler

Views

6433

Build Author

Liam Dahler

Views

6433

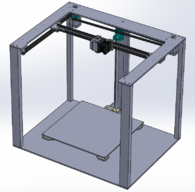

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

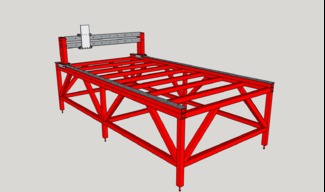

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

Limine3D

Views

4432

Build Author

Limine3D

Views

4432

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Big-X Minimill

Minimill bundle, but with an extended X Axis

Delta without vertices

As this is a build in progress, I will update it as I progress.

Build Author

Mark Carew

Views

16765

Build Author

Mark Carew

Views

16765

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Mark Carew

Views

17675

Build Author

Mark Carew

Views

17675

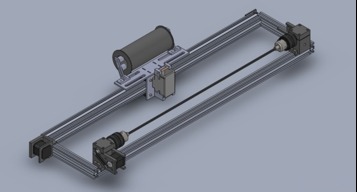

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

SCYBUCK

Views

5074

Build Author

SCYBUCK

Views

5074

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Mark Carew

Views

6072

Build Author

Mark Carew

Views

6072

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Mark Carew

Views

26331

Build Author

Mark Carew

Views

26331

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

RobFromLDMS

Views

5113

Build Author

RobFromLDMS

Views

5113

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Small Slot Cutter

A build to cut .008 inch slots into JB Weld.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Build Author

Vin1027

Views

7239

Build Author

Vin1027

Views

7239

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Doug Rowley

Views

4254

Build Author

Doug Rowley

Views

4254

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

Filament winder ( carbon fiber )

Carbon fiber filament winder

Build Author

DaleShaw

Views

4379

Build Author

DaleShaw

Views

4379

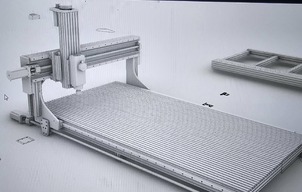

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

1250x1000 Build

A new design of my based on a couple different machines I have seen both on openbuilds and youtube. In the end will have a and X/Y workspace of 1250mm x 1000mm and a Z axis range of about 200mm.

Core XY Beast

Super solid core xy build inspired by the e3d tool changer

Build Author

Forestbird Originals

Views

5333

Build Author

Forestbird Originals

Views

5333

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Build Author

Frank Gore

Views

9684

Build Author

Frank Gore

Views

9684

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Build Author

ckgottabuild

Views

4181

Build Author

ckgottabuild

Views

4181

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

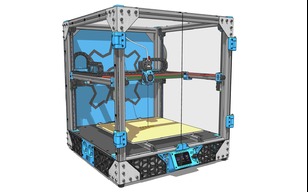

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Build Author

Edgar Mata

Views

30738

Build Author

Edgar Mata

Views

30738

ME - Core XY 3d printer

I wanted to make my own Voron, so I made my own Voron,

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

CONUCON

Views

6556

Build Author

CONUCON

Views

6556

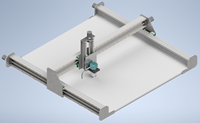

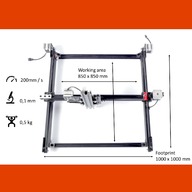

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

Build Author

David E. Flores E.

Views

7169

Build Author

David E. Flores E.

Views

7169

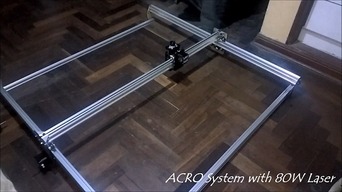

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

Build Author

David E. Flores E.

Views

3066

Build Author

David E. Flores E.

Views

3066

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

Build Author

hbtousa

Views

1944

Build Author

hbtousa

Views

1944

Six_Axis Camera Slider

X is 1000mm, Y is 1500 mm, Z is 1000mm. It Rotates 360 degrees and Tilt also can move 360 degrees. I also have a motor that controls the focus of the camera.

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Build Author

Bobnet

Views

16362

Build Author

Bobnet

Views

16362

Oversize ShapeOko as a 3D printer.

Converting a ShapeOKO into a 3D printer.

Linear Rotational Art.

One Linear Actuator covering two dimensions, WHAT!

Build Author

mirage335

Views

11883

Build Author

mirage335

Views

11883

FlexReplicator

Multi-tool 3D printer, laser cutter, and CNC mill.

Build Author

Bobnet

Views

13250

Build Author

Bobnet

Views

13250

Rackmount + OpenRail

OpenRail attached to a 19" rackmount 15U box.

Build Author

Christer Langley

Views

9386

Build Author

Christer Langley

Views

9386

CNC-Solutions Build

My first Build with V-slot

Build Author

John J Talavera

Views

8392

Build Author

John J Talavera

Views

8392

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

CNC MILLING ROUTER

CNC MILLING ROUTER

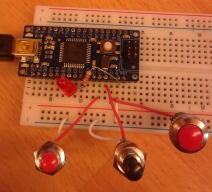

USB Pendant

An USB Pendant for LinuxCNC / Mach3

BldrBox

OpenBuilds box type printer using min-v-wheels for X & Y axis. Designed for plexiglas panel enclosure of build area.

BotMaker

This is a work in progress 3D printer Dimensions are 230x230x340mm height. Print dimensions are: 135x135x160mm. Prototype has a bowden extruder with a J-head hotend. Assembly instructions: http://reprapstyle.blogspot.pt