Build List

-

Active Filters:

cnc

Build Author

Mark Carew

Views

1215434

Build Author

Mark Carew

Views

1215434

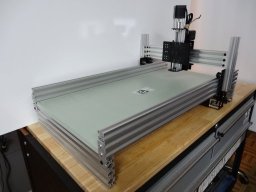

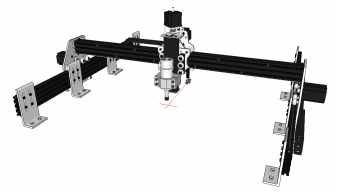

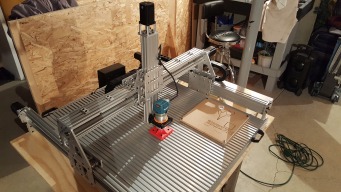

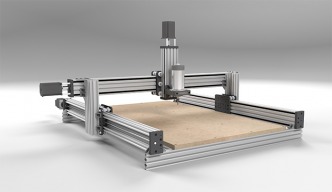

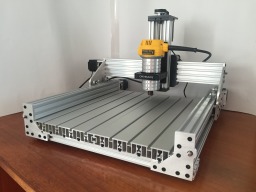

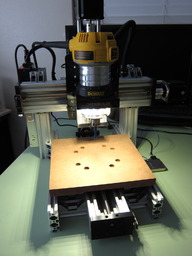

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

Kyo

Views

146054

Build Author

Kyo

Views

146054

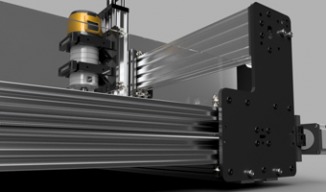

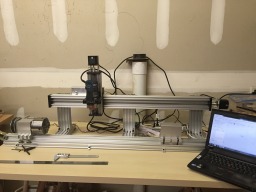

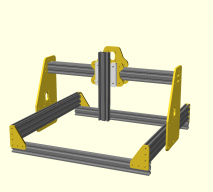

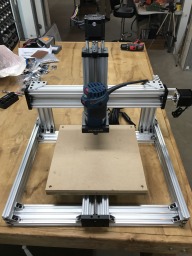

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Build Author

Schematix

Views

158818

Build Author

Schematix

Views

158818

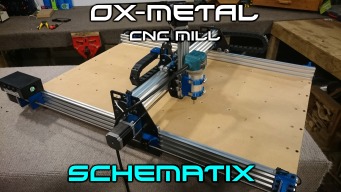

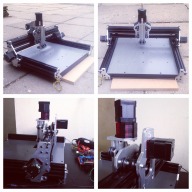

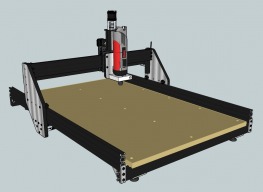

OX-Metal CNC Router Mill

The OX-Metal is based on the original OX CNC mill But with a few modifications and add-ons

Build Author

Michael.M

Views

69770

Build Author

Michael.M

Views

69770

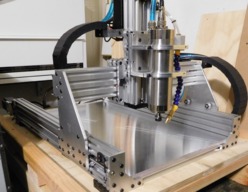

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

C-BEAM-GTC

Building a larger C-BEAM CNC Machine with no previous experience.

Build Author

Mark Carew

Views

243940

Build Author

Mark Carew

Views

243940

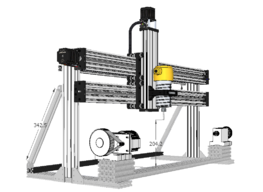

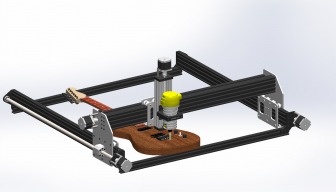

OpenBuilds ACRO System

The OpenBuilds ACRO System was developed to be the most accurate and cost effective positioning system in its class. The ACRO System incorporates the OpenBuilds V-Slot system and, therefore, has the unique ability to expand to multiple sizes creating a size configuration custom to your needs. Choose the size that best fits your workshop. This versatile system allows for precise positioning of many different mountable tools and attachments.

OX AI

This will be an Aluminum OX build. Plates and all design credit goes to Mark from open builds. I may add my own touches but mainly this is to see how Aluminum plates perform

Build Author

T4Concepts

Views

82495

Build Author

T4Concepts

Views

82495

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

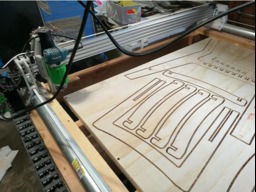

Openbuilds 4x8 cnc

I built this cnc using 2 z axis actuators thinking it would minimize deflection and it seems to be very sturdy. I used 2 1500mm c channels for my x axis, 1 1500mm c channel for my y axis, nema 23 stepper motors, dm556 drivers, 2 24v power supplies, smc5-5-n-n controller, 9mm wide belts, and the Hitachi m12vc router. So far it's working very well with a few hiccups. Programming the controller was a learning experience but I'm very happy with it.

Build Author

Robert Hummel

Views

155200

Build Author

Robert Hummel

Views

155200

Laser V

With such great success/attention my laser got, I ended up with a good friend that would like to dabble in stencil art and so I have decided to share my build with him and you here :) I will be using all the same electronics as in my previous build except the driver boards I will be using are the famous reprap 4988's they are more easy to come by and cost less. I will also be using open builds mini v wheels/v groove extrusion just so I can get a feel for their versatile products

Build Author

Michael.M

Views

46200

Build Author

Michael.M

Views

46200

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

Build Author

Mark Carew

Views

272746

Build Author

Mark Carew

Views

272746

C-Beam® Machine - Plate Maker

This C-beam Machine is an in affordable CNC plate maker and 3D carving machine!

Build Author

sebf34

Views

32447

Build Author

sebf34

Views

32447

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

Build Author

Mark Carew

Views

222238

Build Author

Mark Carew

Views

222238

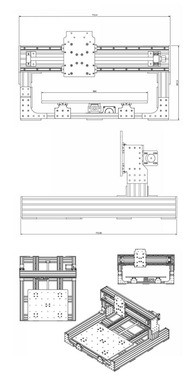

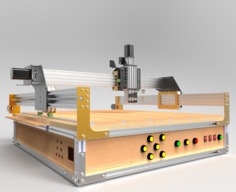

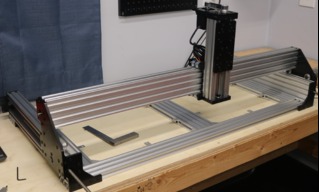

LEAD CNC 1010 (40" x 40")

The OpenBuilds Lead Machine takes us back to the roots of the OpenBuilds modular building system, and has proven itself as an adaptable design that can compete with any machine in its class!

Build Author

Retsaj

Views

76583

Build Author

Retsaj

Views

76583

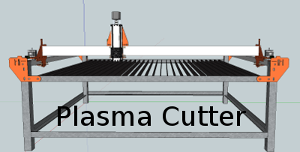

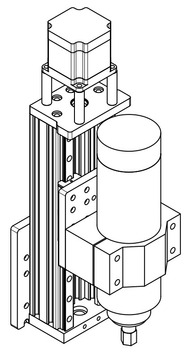

Standalone Torch Height Controller for CNC Plasma Cutting

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

ROUTY CNC Router (V-Slot Belt & Pinion)

A cool little CNC router build that uses the V-Slot belt & pinion drive and stock parts.

Build Author

Robert Hummel

Views

73863

Build Author

Robert Hummel

Views

73863

890KV OX RC spindle

This build is intended as a light alternative to the Dremel rotary tool.

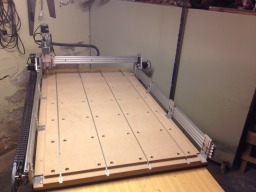

DIY CNC Machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

Build Author

Mark Carew

Views

162735

Build Author

Mark Carew

Views

162735

OpenBuilds MiniMill

This OpenBuilds Mini Mill is a great go-to desktop sized CNC milling plate / part maker and 3D carving machine!

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

Build Author

Leonard Cross

Views

38981

Build Author

Leonard Cross

Views

38981

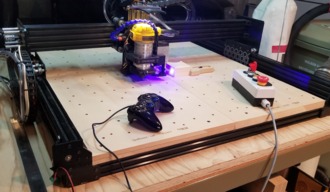

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

Build Author

Savvas

Views

19912

Build Author

Savvas

Views

19912

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

Janis93

Views

16100

Build Author

Janis93

Views

16100

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

LEAD Lathe

I have been toying with the idea of making a 3 axis rotary CNC machine for awhile. I wanted to make it with off the shelf OpenBuilds parts so any one can replicate it and I felt the LEAD High Z Mod would be a good starting point.

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

Build Author

ahayden

Views

27686

Build Author

ahayden

Views

27686

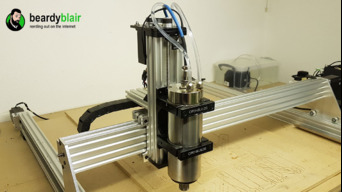

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

Build Author

beardyblair

Views

25497

Build Author

beardyblair

Views

25497

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

Build Author

Jacob Lotter

Views

27950

Build Author

Jacob Lotter

Views

27950

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

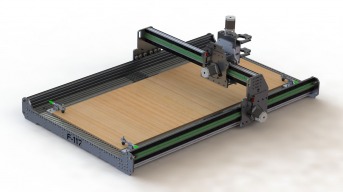

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Build Author

blterry1

Views

19524

Build Author

blterry1

Views

19524

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

Build Author

Robert Hummel

Views

25848

Build Author

Robert Hummel

Views

25848

Stinger V Micro Mill

While building my OX AI I found myself with left over v slot and thought to myself, what do I need that I can build using them? Well since I make a lot of my own PCB boards for projects I figured a micro PCB mill would fit the bill ;) With inspiration from the OX and OX AI I give you the Stinger V :)

Rotary CNC

I'm building a machine specifically for doing 4th axis work on woodwind instruments.

Plasma cutter - 608 on steel tube version

CNC Plasma cutter: 608ZZ on steel square tube linear rollers Welded frame HDT2-15 Belt Drive Tradeweld Cut-40 Plasma cutter with converted hand torch Virtual Torch Height Control through inductive probing - open source electronics project

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Build Author

that-jim

Views

48572

Build Author

that-jim

Views

48572

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

Build Author

Glenn Weston

Views

18824

Build Author

Glenn Weston

Views

18824

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Build Author

roadss

Views

26375

Build Author

roadss

Views

26375

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

Ryan Lock

Views

137131

Build Author

Ryan Lock

Views

137131

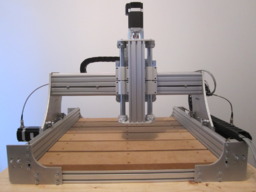

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Charging Ox CNC Machine

A heavily modified Ox CNC build to replace SO2.

Build Author

alex_b

Views

19501

Build Author

alex_b

Views

19501

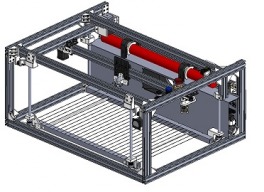

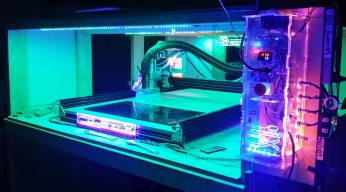

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

Build Author

Ryan Lock

Views

147745

Build Author

Ryan Lock

Views

147745

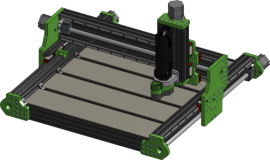

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

Build Author

Mark Carew

Views

70729

Build Author

Mark Carew

Views

70729

High Z Mod for Lead CNC

The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router.

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

Build Author

kallibaba

Views

35865

Build Author

kallibaba

Views

35865

CNC Sand and Spraycalk drawmaschine

A little CNC Sand and Spraycalk drawmaschine More and details in the next weeks

Prototype Rack-n-Pinion 4'x8'

This is a custom gear rack drive machine with a 4'x8' cut capacity.

Build Author

Lumberjack Engineering

Views

20429

Build Author

Lumberjack Engineering

Views

20429

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

3D printed Laser Engraver

i´ve designing this laser taking care of every part to be functional, This laser has Endstops mounts on the corners and the X axis both sides too. The corners has fasbelt tension knobs for easy operation. The laser mount has adjustable knob to manually rise or down the laser for focusing purpose. all the parts have been printed at 65% infill a 2 perimeter lines just to make the parts stronger. Attached you will find a part list with quantity and link where to buy. SIZE 1mts x 75cm Built area

Build Author

Serge E.

Views

61450

Build Author

Serge E.

Views

61450

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

OX Tale

1000mm x 750mm OX with some planned enhancements. My first venture into CNC.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Build Author

Troy Proffitt

Views

29525

Build Author

Troy Proffitt

Views

29525

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Mark Carew

Views

76222

Build Author

Mark Carew

Views

76222

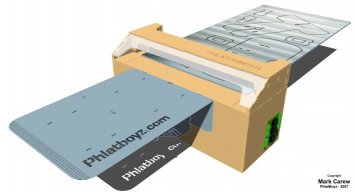

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Build Author

UltiBots

Views

38201

Build Author

UltiBots

Views

38201

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

Build Author

Michael.M

Views

9881

Build Author

Michael.M

Views

9881

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Rotary Axis OX Derivitive

A Rotary Axis CNC router based on the OX CNC Router

Build Author

mytechno3d

Views

37432

Build Author

mytechno3d

Views

37432

Plasma cutting table

This is our plasma cutting table , based on the famous OX CNC . Can cut up to 15 mm ( steel , stainless , aluminium ) with a really good accuracy and at a really high speed .

Build Author

Savvas

Views

14578

Build Author

Savvas

Views

14578

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Gooshpoo

Views

9630

Build Author

Gooshpoo

Views

9630

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

Kyo

Views

46752

Build Author

Kyo

Views

46752

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

MyCNC(1000mm x 1500mm)

My CNC project

Build Author

Ronald van Arkel

Views

33751

Build Author

Ronald van Arkel

Views

33751

Routy GT2 290 BSX CNC Router, Low Cost and Good!

The Routy GT2 300 BSX CNC Router is a Low Cost CNC build. It performs the same as the larger Routy's from OpenBuilds but doesn't break the bank!

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

Build Author

jamesdjadams

Views

12433

Build Author

jamesdjadams

Views

12433

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Build Author

Spark Concepts

Views

17199

Build Author

Spark Concepts

Views

17199

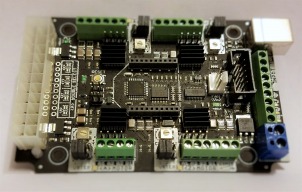

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

Build Author

Mike Campbell

Views

11440

Build Author

Mike Campbell

Views

11440

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Mark Carew

Views

75538

Build Author

Mark Carew

Views

75538

X Y Table OpenRail / V-Slot Build Examples

The X/Y table system is a great starting point for many CNC projects giving you the ability to move an object on the X and Y axis in a simple compact style.

Mini-OX

An OX-inspired mini desktop mill. Designed in OpenSCAD, these parts are fully parametric and can be customized to your liking.

Build Author

Matt Nelson

Views

12508

Build Author

Matt Nelson

Views

12508

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

StrictlyScale

Views

10907

Build Author

StrictlyScale

Views

10907

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

Rick 2.0

Views

22264

Build Author

Rick 2.0

Views

22264

C-Beam Mini Mite

A small system with a big bite. Design achieves a good balance between machine size vs. build area, rigidity and ease of construction all while keeping build cost as low as possible.

Build Author

winand

Views

18261

Build Author

winand

Views

18261

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

Build Author

Julius

Views

25789

Build Author

Julius

Views

25789

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

OffAxis

Views

7989

Build Author

OffAxis

Views

7989

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

viktop

Views

19165

Build Author

viktop

Views

19165

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

The Frog: CNC Router

Frog CNC Router. Inspired by OX and "Routy". 24"x36" active working area, approx. 3" usable Z motion.

Build Author

Spark Concepts

Views

75260

Build Author

Spark Concepts

Views

75260

CNC xPRO Driver

Spark Concepts CNC xPRO Driver. A new GRBL compatible, all-in-one stepper driver board with 4 motor controllers for XYZ + 1 clone (or rotary!). Capable of powering your next build with an ATX PSU (or 12V 2 wire supply), and ready for wireless printing. Compatible with Arduino (wireless robots anyone?)

Sea-OX

This is my first CNC build. The Sea-OX is a machine built out of three 1000mm C-Beams. I plan to have a Y length of 1000mm and a X length of 650mm. The Z should have the ability to move approximately 100mm.

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Build Author

JWhitten

Views

14343

Build Author

JWhitten

Views

14343

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Eric Jacobsson

Views

15786

Build Author

Eric Jacobsson

Views

15786

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Fixed Gantry CNC Router

A fixed gantry router using OpenBuilds control and electronics.

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Build Author

Peter Oakes

Views

44691

Build Author

Peter Oakes

Views

44691

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Schematix OX metal build

OX metal build from an noob

Build Author

Mark Carew

Views

37012

Build Author

Mark Carew

Views

37012

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

pedrofernandez

Views

12353

Build Author

pedrofernandez

Views

12353

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Mark Carew

Views

78967

Build Author

Mark Carew

Views

78967

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

92217

Build Author

Mark Carew

Views

92217

BlackBox Motion Control System

The Openbuilds BlackBox is a new system evolved around a set of subsystems that cover more than just control and also more than just CNC type applications! With a plug-and-play easy connection system this controller can be used with ease, without sacrificing power.

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

that-jim

Views

12625

Build Author

that-jim

Views

12625

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

alex_b

Views

17678

Build Author

alex_b

Views

17678

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Build Author

AK-Creation

Views

15158

Build Author

AK-Creation

Views

15158

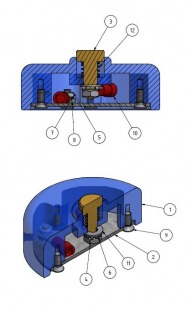

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.