Build List

-

Active Filters:

g

Guitar shop CNC

Great bit of kit time will tell if it is up to the job

Build Author

JP Warnke

Views

12701

Build Author

JP Warnke

Views

12701

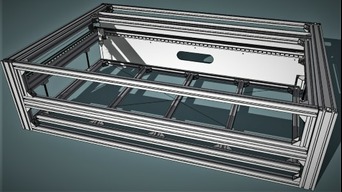

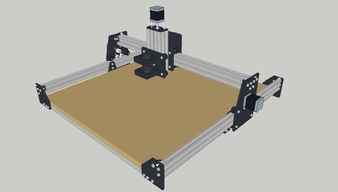

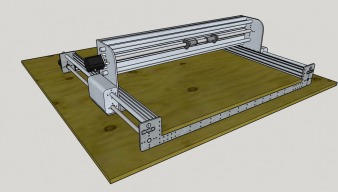

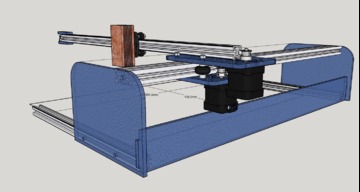

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

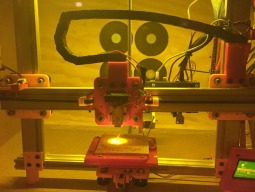

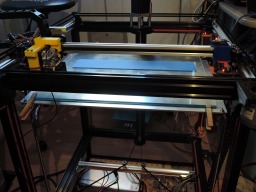

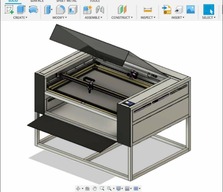

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

Build Author

Jason @ MCC

Views

12627

Build Author

Jason @ MCC

Views

12627

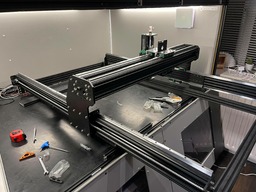

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Build Author

Kyo

Views

12424

Build Author

Kyo

Views

12424

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

Build Author

nickchnv

Views

12381

Build Author

nickchnv

Views

12381

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12336

Build Author

AndersFaust

Views

12336

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

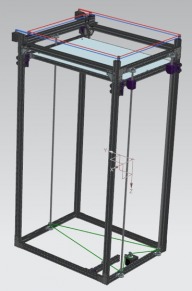

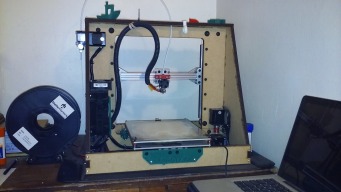

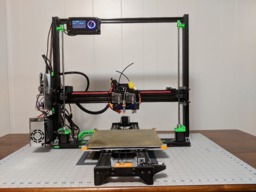

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

Build Author

j0achim

Views

12204

Build Author

j0achim

Views

12204

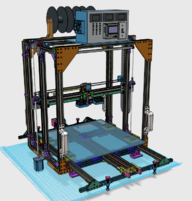

CoreXY - e3d inspired

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Build Author

GDanger117

Views

12184

Build Author

GDanger117

Views

12184

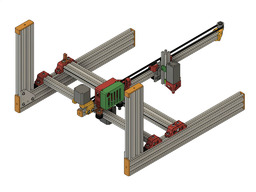

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Matt Nelson

Views

12168

Build Author

Matt Nelson

Views

12168

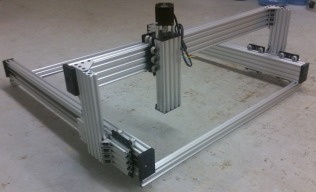

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

jamesdjadams

Views

12113

Build Author

jamesdjadams

Views

12113

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Build Author

pedrofernandez

Views

12100

Build Author

pedrofernandez

Views

12100

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

John J Talavera

Views

12062

Build Author

John J Talavera

Views

12062

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

Build Author

Andrew Helsel

Views

12036

Build Author

Andrew Helsel

Views

12036

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

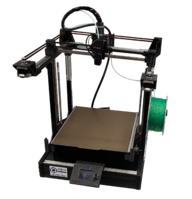

Vulcan Pro V1

A posi-drive leveling printer in 300x300x380mm format that easily breaks down for suitcase size shipping.

Build Author

Scott Martinez

Views

11993

Build Author

Scott Martinez

Views

11993

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

Anthony Bolgar

Views

11905

Build Author

Anthony Bolgar

Views

11905

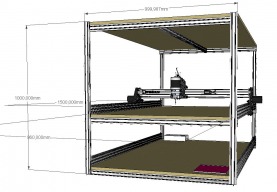

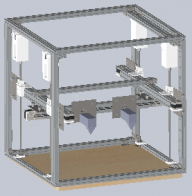

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Build Author

mirage335

Views

11881

Build Author

mirage335

Views

11881

FlexReplicator

Multi-tool 3D printer, laser cutter, and CNC mill.

Build Author

Andreas Bockert

Views

11804

Build Author

Andreas Bockert

Views

11804

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

reef

Views

11792

Build Author

reef

Views

11792

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

BNMaker

Views

11731

Build Author

BNMaker

Views

11731

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

Laser engraving machine

Second better project, high durable mainframe, silent work, non vibration.

Build Author

sw3Dp

Views

11711

Build Author

sw3Dp

Views

11711

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

Build Author

lekey

Views

11572

Build Author

lekey

Views

11572

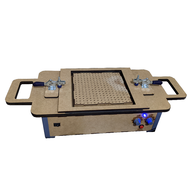

Modular Desktop Vacuum Former

This is a small desktop vacuum former that can be connected to a shop-vac and an electric heat source (like a grill for instance). You can control the time each appliance stays turned on, and the vacuum is automatically turned on when the tray is placed on top of the model. The vacuum table is 20x20cm wide, and I've tested it mostly with 1mm thick PET sheets.

Build Author

OpenBuilds

Views

11521

Build Author

OpenBuilds

Views

11521

Swing Arm

Simple Swing Arm Build for the Modular Table Series. Create a simple vacuum swing arm that swings over your machine keeping your vacuum hose and router cord, etc. up and out of the way

Build Author

Joe Garritano

Views

11502

Build Author

Joe Garritano

Views

11502

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Build Author

Scotty Orr

Views

11428

Build Author

Scotty Orr

Views

11428

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

Beam

Views

11397

Build Author

Beam

Views

11397

DIY Flywheel Camera Slider

My take on a non affordable slider.

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

Build Author

David Florian

Views

11357

Build Author

David Florian

Views

11357

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Build Author

dreys

Views

11308

Build Author

dreys

Views

11308

Was once a mini mill

Working progress.

Build Author

Glenn Weston

Views

11208

Build Author

Glenn Weston

Views

11208

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

jjcolletta

Views

11067

Build Author

jjcolletta

Views

11067

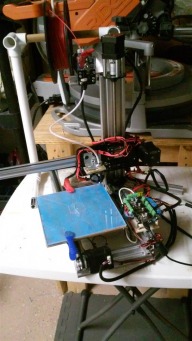

First 3d build

I am building a simple home brewed printer. I have a background in industrial automation so I figured how hard could this be. The mechanical build was pretty smooth as was the electrical side. Now just getting plastic out the hotend is my stopping point.

Build Author

Mike Campbell

Views

10961

Build Author

Mike Campbell

Views

10961

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Sonny Lowe

Views

10761

Build Author

Sonny Lowe

Views

10761

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Rob Taylor

Views

10696

Build Author

Rob Taylor

Views

10696

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

dcarlisle

Views

10654

Build Author

dcarlisle

Views

10654

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Build Author

Keteland

Views

10633

Build Author

Keteland

Views

10633

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Naomi Wu

Views

10626

Build Author

Naomi Wu

Views

10626

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Dedicated Compact Rotary Axis Laser Engraver

Compact Dedicated Rotary Axis Laser Engraver

Apple Crate CNC

Low cost, apple crate framed CNC.

Build Author

Kyo

Views

10522

Build Author

Kyo

Views

10522

Fina

This is Fina; My Lautr3k inspired build.

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

Build Author

CNCGear

Views

10395

Build Author

CNCGear

Views

10395

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Build Author

Lasersc

Views

10386

Build Author

Lasersc

Views

10386

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

TABLE OX Router/3D-Printer

OX MultiMachine

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Build Author

Pendragon

Views

10248

Build Author

Pendragon

Views

10248

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

Laseroko Laser Engraver Build

After expanding a Shapeoko 2 with the rails and motors left over, make yourself a laser engraver.

Build Author

jaron kennell

Views

10178

Build Author

jaron kennell

Views

10178

Rezo 1390 100W CO2 Laser

This laser is a beast. Designed by Jonathan Frost, and built with 45x45mm aluminum for ultimate rigidity. It has a 4'x3' bed with a pass through that can be utilized to cut full 8x4' sheets of plywood, and has a motorized bed. Rēzo is not only faster and more capable than lasers like Thunder Lasers Nova 51 and Aeon Nova 10, but the final build costs are 40-60% less than said commercially available machines. Plans can be found at https://rezo1390.bigcartel.com/product/rezo-1390-plans

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

BinaryConstruct

Views

10117

Build Author

BinaryConstruct

Views

10117

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Viking OX

My OX cnc upgrade.

Build Author

Mark Rehorst

Views

10073

Build Author

Mark Rehorst

Views

10073

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

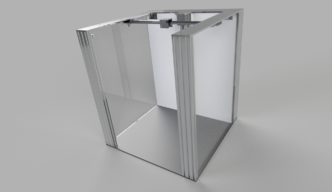

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Build Author

COMsulting

Views

9976

Build Author

COMsulting

Views

9976

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

Build Author

crypt-tek

Views

9941

Build Author

crypt-tek

Views

9941

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

Bob Darrow

Views

9867

Build Author

Bob Darrow

Views

9867

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Build Author

Robert Mech

Views

9849

Build Author

Robert Mech

Views

9849

LayerFused X301 - CoreXY Large Volume Printer

The X301 is a CoreXY 3D Printer that has a small footprint and a large 300x300x330 build area. The open style of this printer breaks the "Cube" mold of many other printers in this class but still retails rigidity and great performance.

Build Author

M1dn1ghtN1nj4

Views

9837

Build Author

M1dn1ghtN1nj4

Views

9837

The Beast

This is a heavily modified system based on the RatRig V-Cast. Lots of personal touches, and a LOT more to come!

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

Build Author

deltajegga

Views

9760

Build Author

deltajegga

Views

9760

THE delta

probably as big as you'd want it...

Build Author

Christian James

Views

9716

Build Author

Christian James

Views

9716

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Hydraulic lifting table

I started this project without drawing. in itself this went fine with some minor adjustments. My profession is machine builder that might make it a little easier. I still enjoy it every day.

Horizontal Cantilever or Vertical Diode Laser Engraver

Light weight portable Laser Engraver (6.5lbs - 12lbs)

Build Author

Keith Davis

Views

9686

Build Author

Keith Davis

Views

9686

Upgrading Your 3D Printer With Synchronous Leveling

Upgrading printers for Synchronous Leveling

Build Author

Frank Gore

Views

9674

Build Author

Frank Gore

Views

9674

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Ike:Laser

A 2 axis laser engraving machine, with a manual Z axis.

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

Build Author

mathom713

Views

9541

Build Author

mathom713

Views

9541

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

Gargoile reproduction C-Beam™ Machine - Plate Maker

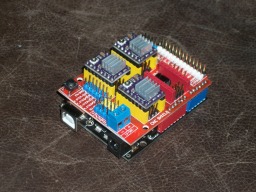

A stock C-Beam with a CNC shield with DRV8825's

Build Author

Maxime Favre

Views

9457

Build Author

Maxime Favre

Views

9457

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

Nicademus

Views

9411

Build Author

Nicademus

Views

9411

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Delta without vertices

As this is a build in progress, I will update it as I progress.

Build Author

Christer Langley

Views

9382

Build Author

Christer Langley

Views

9382

CNC-Solutions Build

My first Build with V-slot

Build Author

Jesse Jenkins

Views

9352

Build Author

Jesse Jenkins

Views

9352

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

CreativeTools

Views

9305

Build Author

CreativeTools

Views

9305

Universal stand-alone filament spool holder (Fully 3D-printable)

A practical rotating and stand-alone spool holder which fits any filament extrusion 3D-printer. Several base files provided which make it fit different extruded aluminium profiles.

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

Build Author

Rwetzler

Views

9237

Build Author

Rwetzler

Views

9237

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

Gooshpoo

Views

9206

Build Author

Gooshpoo

Views

9206

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Sergio Di Ventura

Views

9156

Build Author

Sergio Di Ventura

Views

9156

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

Quentin Karmark

Views

9126

Build Author

Quentin Karmark

Views

9126

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

Build Author

zann68

Views

9086

Build Author

zann68

Views

9086

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

J-Wahl Dezign

Views

9075

Build Author

J-Wahl Dezign

Views

9075

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

recoush

Views

9054

Build Author

recoush

Views

9054

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Bridge Port

Views

9046

Build Author

Bridge Port

Views

9046

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

Build Author

motopreserve

Views

9004

Build Author

motopreserve

Views

9004

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...