Build List

-

Active Filters:

z

Build Author

Ryan Lock

Views

147402

Build Author

Ryan Lock

Views

147402

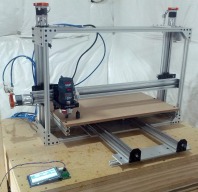

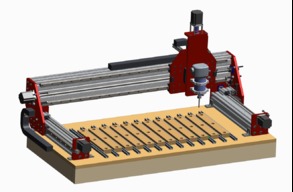

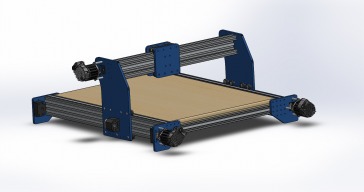

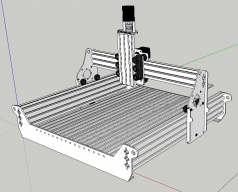

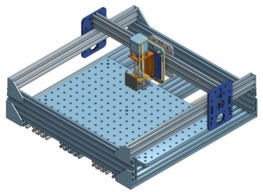

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

Build Author

Ryan Lock

Views

137049

Build Author

Ryan Lock

Views

137049

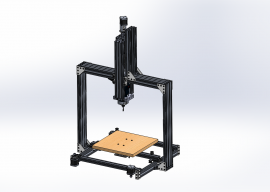

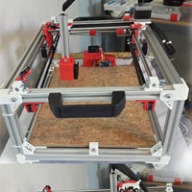

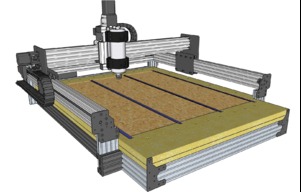

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Build Author

Indieflow

Views

116234

Build Author

Indieflow

Views

116234

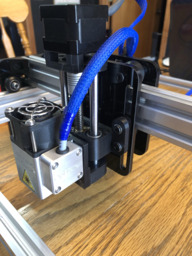

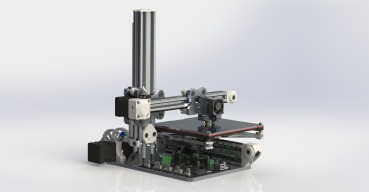

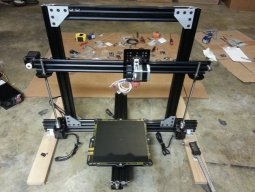

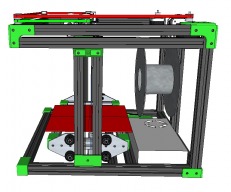

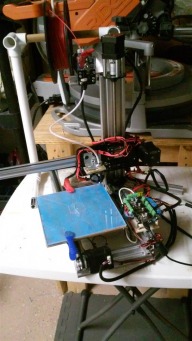

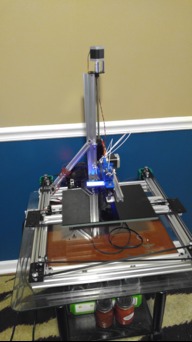

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Build Author

Mark Carew

Views

110101

Build Author

Mark Carew

Views

110101

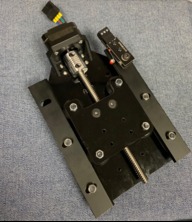

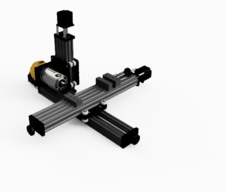

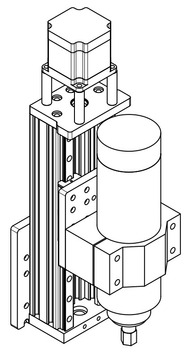

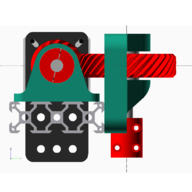

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

pek

Views

85235

Build Author

pek

Views

85235

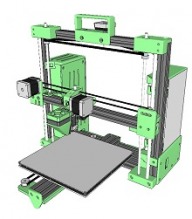

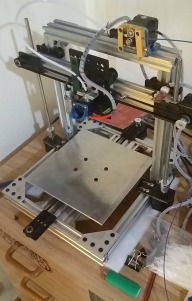

Prusa i3 Bear Upgrade V2

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Build Author

T4Concepts

Views

82269

Build Author

T4Concepts

Views

82269

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

openhardwarecoza

Views

78238

Build Author

openhardwarecoza

Views

78238

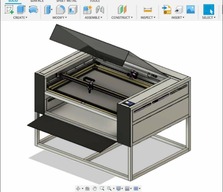

openBuilds FreeBURN-1 V-slot CO2 Laser (60-100w)

DIY Lasercutter: Budget orientated, medium sized (60-100w), safety first, based on Lasersaur software toolchain

Build Author

Mark Carew

Views

76122

Build Author

Mark Carew

Views

76122

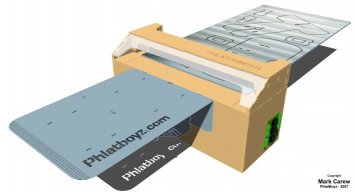

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

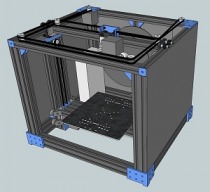

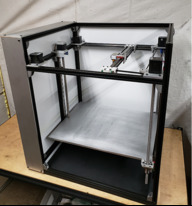

CoreXY Enclosed

A compact, enclosed Core XY design, based on off-the-shelf parts.

Build Author

Cuong Vu

Views

35977

Build Author

Cuong Vu

Views

35977

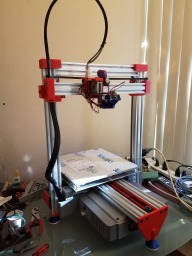

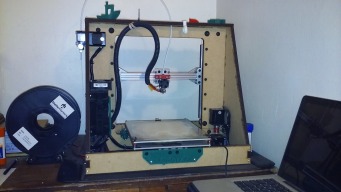

3D Printer

It took me 18 long nights to build it

Build Author

Keith Davis

Views

35698

Build Author

Keith Davis

Views

35698

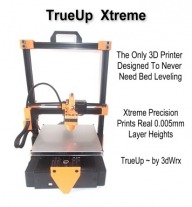

OneZ i3

A quiet, 8inx8in build area, Cartesian printer with permanently level bed. This is a compact, solid, inexpensive printer that will reliably print any type filament for thousands of hours while you sleep, fish, or play ball in the park.

Build Author

DistortedDesigns

Views

34358

Build Author

DistortedDesigns

Views

34358

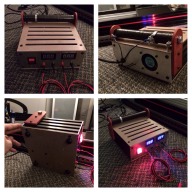

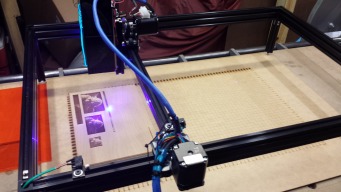

Project Death Star - DistortedDesigns Laser Engraver

2 watt Laser Engraver, Simple, Fairly Low Cost, and Portable

Build Author

sebf34

Views

32385

Build Author

sebf34

Views

32385

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

TrueUp Glide

A Cartesian printer using bushings for the Z axis instead of wheels or linear bearings. The design also synchronizes two Z axis screws with a timing belt for a level lift. The ratio of the drive pulley and Z axis pulleys produce .005 lift per full step on a 200 step motor, eliminating layer resolution "drift" caused by microstepping.

Build Author

Julius

Views

25747

Build Author

Julius

Views

25747

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

TrueUp Kit Version

A Cartesian printer using bushings for the Z axis instead of wheels or linear bearings. The design also synchronizes two Z axis screws with a timing belt for a level lift. The ratio of the drive pulley and Z axis pulleys produce .005 lift per full step on a 200 step motor, eliminating layer resolution "drift" caused by microstepping.

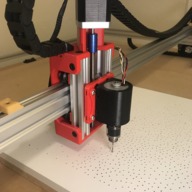

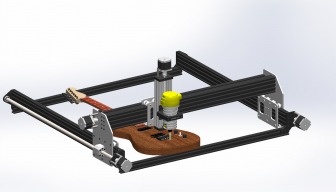

OpenBuilds ACRO Z Axis

Z-Axis for OpenBuilds ACRO system. It is sturdy enough to carry a small drill.

Build Author

SecretSpy711

Views

22944

Build Author

SecretSpy711

Views

22944

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

AK-Creation

Views

22771

Build Author

AK-Creation

Views

22771

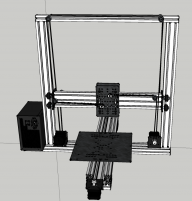

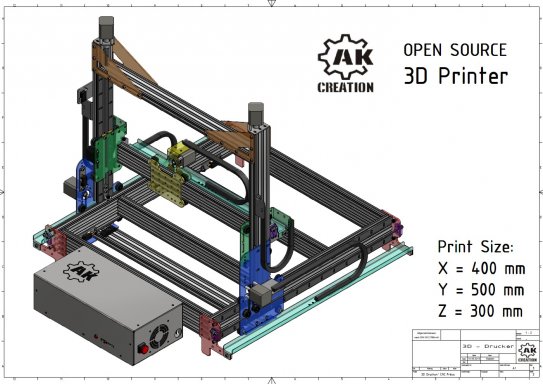

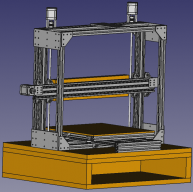

3D Printer - Big Size

I creat a open source 3D Printer to print big things. Print size: 400x500x300 mm. You can download the Drawing in PDF and in Inventor 2013 format. The unwinding drawings are also included. I take some detail photos for a better understanding.

Ooznest Ox with 3D Printed Gantry Plates

Ooznest Ox with gantry plates and end caps 3D printed in ABS rather than aluminum.

Build Author

Keith Davis

Views

20989

Build Author

Keith Davis

Views

20989

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

Z-Axis for Laser Diode

Custom Z Axis for OptLaser 6watt and the Acro System

Build Author

zelos

Views

19487

Build Author

zelos

Views

19487

ZelosLaser Engraver/Cutter 2.0 : Sturdy & Versatile

Zelos Laser Cutter Version 2.0 GRBL Shield with Nema 17 motors. 2 Watt laser for cutting and fine grayscale pictures built very sturdy and modular

Build Author

Steve hope

Views

19365

Build Author

Steve hope

Views

19365

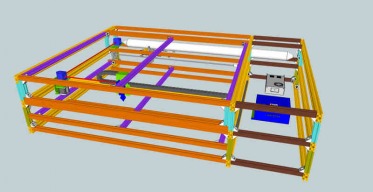

8x4 CNC build

Routy cnc upgrade.

Build Author

Kims3DIY

Views

18495

Build Author

Kims3DIY

Views

18495

Beamlazer Laser cutter CO2 100W

Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Then i decided to build my own laser, with some easier workflow and support for Windows 10. Since im still a student i have limited resources, so i will try too use scrap parts as much as possible. I will publish photos and updates during my build continously. Gladly taking advices from others.

Build Author

Robert E. Nee

Views

17977

Build Author

Robert E. Nee

Views

17977

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Build Author

Keith Davis

Views

17861

Build Author

Keith Davis

Views

17861

OneZ

OneZ gets it's name from it's most unique feature - only motor for the Z axis while maintaining the stability of two bearing guides for the Z axis. Reduction to one Z motor eliminates need for auto bed leveling.

DIY anodizing power supply

How to make your own anodizing power supply on a budget

Build Author

RobSaunders

Views

17370

Build Author

RobSaunders

Views

17370

Laser Cutter/Engraver OptLaser 6W with Z-axis

This was my first attempt for a laser platform. I'm using the OpenBuilds ACRO 20"x40 platform, 6W OptLaser, homemade z height and the xPro driver board.

Build Author

Ronald van Arkel

Views

16826

Build Author

Ronald van Arkel

Views

16826

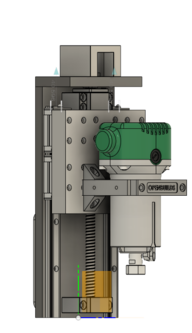

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

Build Author

shanehooper

Views

16331

Build Author

shanehooper

Views

16331

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Teflon4

Views

16091

Build Author

Teflon4

Views

16091

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

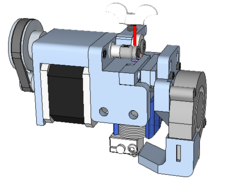

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

Build Author

Mark Carew

Views

14992

Build Author

Mark Carew

Views

14992

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Build Author

Tim Pierce

Views

14619

Build Author

Tim Pierce

Views

14619

Openbuilds V slot Rail extrusion retrofits for Lulzbot 4/5 Taz Printers (X, Y and Z axis)

This project shows how to use Openbuilds Vv slot extrusions and wheels to retrofit a Lulzbot Taz 4 or 5 printer. These modifications improve layer consistency, eliminate nozzle and bed sag, and allow for larger toolhead mounting. Project updates and newer accessory files may be located at http://www.thingiverse.com/piercet/designs

Build Author

that-jim

Views

12535

Build Author

that-jim

Views

12535

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

Andreas Bockert

Views

12220

Build Author

Andreas Bockert

Views

12220

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

David Florian

Views

12124

Build Author

David Florian

Views

12124

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Build Author

Scotty Orr

Views

12016

Build Author

Scotty Orr

Views

12016

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

evil2002usna

Views

11695

Build Author

evil2002usna

Views

11695

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

jaron kennell

Views

11488

Build Author

jaron kennell

Views

11488

Rezo 1390 100W CO2 Laser

This laser is a beast. Designed by Jonathan Frost, and built with 45x45mm aluminum for ultimate rigidity. It has a 4'x3' bed with a pass through that can be utilized to cut full 8x4' sheets of plywood, and has a motorized bed. Rēzo is not only faster and more capable than lasers like Thunder Lasers Nova 51 and Aeon Nova 10, but the final build costs are 40-60% less than said commercially available machines. Plans can be found at https://rezo1390.bigcartel.com/product/rezo-1390-plans

Ooznest OX CNC Build

Ooznest OX CNC build

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

jjcolletta

Views

11330

Build Author

jjcolletta

Views

11330

First 3d build

I am building a simple home brewed printer. I have a background in industrial automation so I figured how hard could this be. The mechanical build was pretty smooth as was the electrical side. Now just getting plastic out the hotend is my stopping point.

Build Author

Rob Taylor

Views

11248

Build Author

Rob Taylor

Views

11248

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

Maxime Favre

Views

9627

Build Author

Maxime Favre

Views

9627

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

recoush

Views

9575

Build Author

recoush

Views

9575

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Anglesachse

Views

9133

Build Author

Anglesachse

Views

9133

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

CoreXZ

I am building a H bot style printer so this design will not be finished any more than it is.

Build Author

mikev

Views

8747

Build Author

mikev

Views

8747

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Neptunes Guitars

Views

8644

Build Author

Neptunes Guitars

Views

8644

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

Build Author

Sam Dobbie

Views

7998

Build Author

Sam Dobbie

Views

7998

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

Taz_Mega

Mega-sized Taz machine. Supports many tools (extrusion, laser, mill, etc) simultaneously.

Build Author

Carl Siren

Views

7801

Build Author

Carl Siren

Views

7801

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Build Author

Josh Mascote

Views

7614

Build Author

Josh Mascote

Views

7614

Z3D Delta Printer

Berrybot inspired delta 3d printer with a few other tweaks and modifications.

Build Author

Jacob Christiansen

Views

7574

Build Author

Jacob Christiansen

Views

7574

ACRO 1010 with custom Z axis

This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting.

Build Author

Tom Dirriwachter

Views

7489

Build Author

Tom Dirriwachter

Views

7489

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

mirage335

Views

7480

Build Author

mirage335

Views

7480

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

openhardwarecoza

Views

7235

Build Author

openhardwarecoza

Views

7235

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

Build Author

joetemus

Views

7096

Build Author

joetemus

Views

7096

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Z Axis for ACRO

Created a small Z axis for the ACRO motion system. I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. Also wanted to be able to vary the height for multiple cutting passes on some materials. Try to stick to a similar aesthetic as the original ACRO system and plates.

Build Author

txcomp

Views

7081

Build Author

txcomp

Views

7081

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

thehans

Views

6858

Build Author

thehans

Views

6858

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

2SIsurf

Views

6805

Build Author

2SIsurf

Views

6805

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

Build Author

Hussein Dermay

Views

6735

Build Author

Hussein Dermay

Views

6735

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Terone Burgenheim

Views

6618

Build Author

Terone Burgenheim

Views

6618

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Build Author

Camvec

Views

6410

Build Author

Camvec

Views

6410

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

inhan

Views

6353

Build Author

inhan

Views

6353

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Build Author

Gary Bonard

Views

6329

Build Author

Gary Bonard

Views

6329

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

Dave420

Views

6270

Build Author

Dave420

Views

6270

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

Build Author

OpenBuilds

Views

6262

Build Author

OpenBuilds

Views

6262

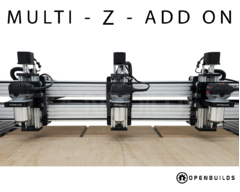

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Build Author

Jacob Lotter

Views

6237

Build Author

Jacob Lotter

Views

6237

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Build Author

BCulbertson

Views

5937

Build Author

BCulbertson

Views

5937

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

Todd Brous

Views

5903

Build Author

Todd Brous

Views

5903

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

Build Author

Ted Moyer

Views

5721

Build Author

Ted Moyer

Views

5721

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Build Author

Keith Davis

Views

5568

Build Author

Keith Davis

Views

5568

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Z Floating Head

It's a Z floating head idea. Works well. Recommend cleaning the inside of your holes well with Q tips, and polishing the 1/4-20 bolts with car wax and you won't need oil as it slides perfectly. Hope this helps

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Build Author

EvanH

Views

5336

Build Author

EvanH

Views

5336

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

Build Author

patdee

Views

5267

Build Author

patdee

Views

5267

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

SCYBUCK

Views

5240

Build Author

SCYBUCK

Views

5240

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

James Evanko

Views

5072

Build Author

James Evanko

Views

5072

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Build Author

Bikes and Beer

Views

5037

Build Author

Bikes and Beer

Views

5037

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure