CNC ROUTER BUILDS

Build Author

Jay Almers

Views

8042

Build Author

Jay Almers

Views

8042

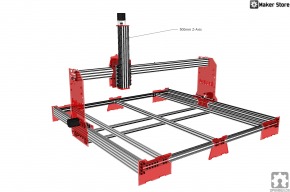

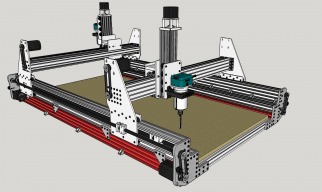

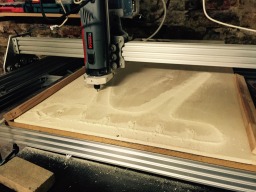

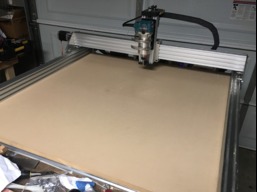

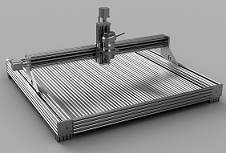

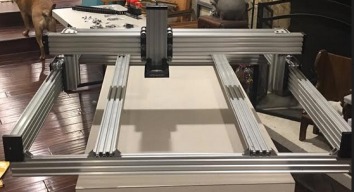

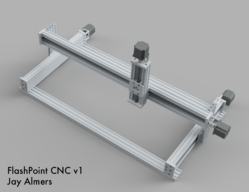

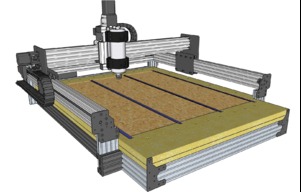

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

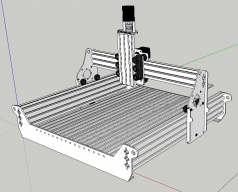

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

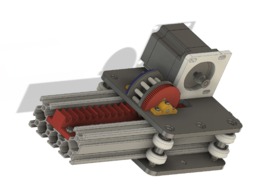

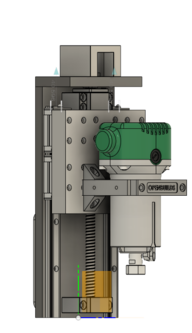

RRP - Roller Rack Pinion System

Current progress uses existing openbuilds bearings, but also uses 8mm shafts (custom)

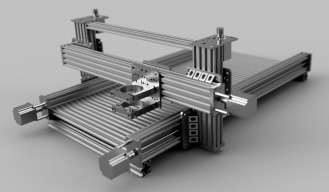

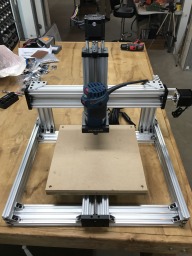

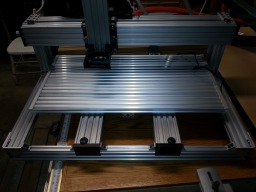

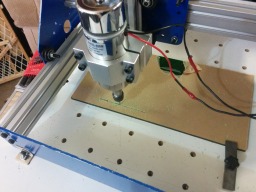

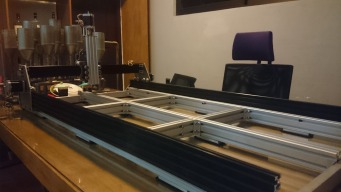

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

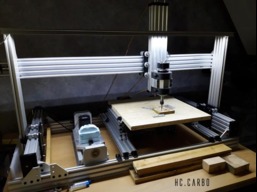

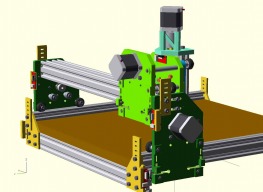

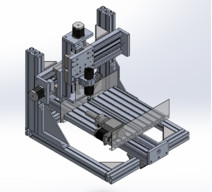

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

Build Author

d0rk1e

Views

7781

Build Author

d0rk1e

Views

7781

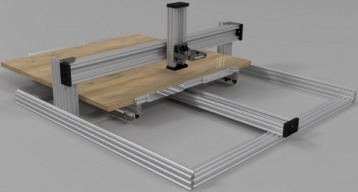

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

Build Author

Wes Dwight

Views

7766

Build Author

Wes Dwight

Views

7766

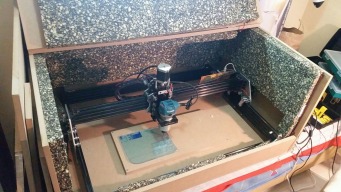

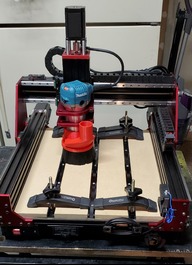

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

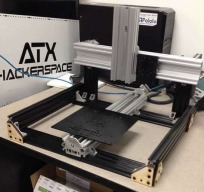

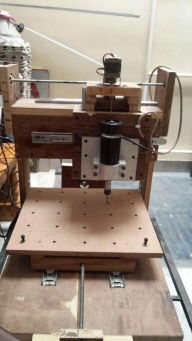

First CNC Router

My very first CNC Router build. It's completely scratch built.

Build Author

OffAxis

Views

7747

Build Author

OffAxis

Views

7747

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

tmadrms

Views

7735

Build Author

tmadrms

Views

7735

C-Beam Mods

C-beam machine mods.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

Build Author

Weldsmith

Views

7729

Build Author

Weldsmith

Views

7729

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Build Author

Brandon Satterfield

Views

7719

Build Author

Brandon Satterfield

Views

7719

SMW3D OX

The SMW3D OX, original other than a lot of learning!

C_Beam X5L Hybrid_Tank

classic router with a ab table

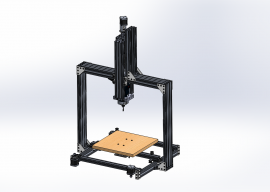

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

Sphinx 66

A Sphinx Linear rail build (600mm x 600mm) hence the title Sphinx66. Plates supplied by Chris Laidlaw. Linear rails used MGN15

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Build Author

Carl Siren

Views

7662

Build Author

Carl Siren

Views

7662

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

KillerBee 1515 customized

Killerbee 1515 with modifications.

Build Author

Corey Corbin

Views

7609

Build Author

Corey Corbin

Views

7609

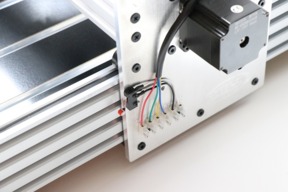

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

Ooznest Moded CNC

Modded OX with full nema23 4 point support

My Second CNC

In short...this was a fun project.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Build Author

Matt Barile

Views

7525

Build Author

Matt Barile

Views

7525

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Build Author

Shaun Weitzel

Views

7509

Build Author

Shaun Weitzel

Views

7509

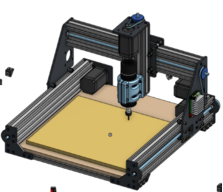

OpenBuilds Lead 1515

First build of a Lead 1515!

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

My Little OX

This build has been an educational experience. Software and hardware alike.

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Brokkr CNC 2.0

1M C-beam xy variant

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Build Author

Vin1027

Views

7352

Build Author

Vin1027

Views

7352

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

k nest

This Build Is Is Inspired By OOZ Nest CNC, But With Some Changes,

Build Author

ChrisViral

Views

7178

Build Author

ChrisViral

Views

7178

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

TurfnSurf

Views

7155

Build Author

TurfnSurf

Views

7155

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

CNC MILLING ROUTER

CNC MILLING ROUTER

Build Author

openhardwarecoza

Views

7140

Build Author

openhardwarecoza

Views

7140

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

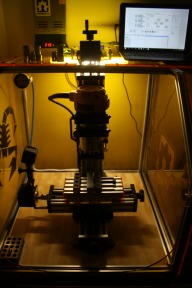

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Birdie CNC

OpenBuilds CNC 500x500

Build Author

Fábio Pires

Views

7061

Build Author

Fábio Pires

Views

7061

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Meister-CNC

This is a cnc router with 3 axis and a kress 1050 motor. Its 140x120cm and a homebuild with your help!

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Sonny Lowe

Views

7013

Build Author

Sonny Lowe

Views

7013

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Build Author

Hytech2k

Views

6959

Build Author

Hytech2k

Views

6959

Micro Ox 2 x 2

Micro Ox Build

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

Build Author

Stokrotka74

Views

6952

Build Author

Stokrotka74

Views

6952

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Small Red OX

A small router for thin plate stock

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

Build Author

txcomp

Views

6867

Build Author

txcomp

Views

6867

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

joetemus

Views

6854

Build Author

joetemus

Views

6854

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

CONUCON

Views

6843

Build Author

CONUCON

Views

6843

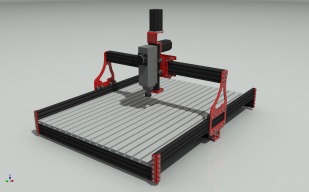

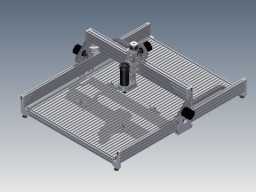

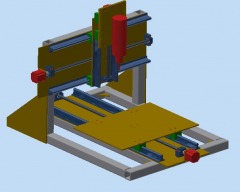

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

Build Author

Vunnie

Views

6808

Build Author

Vunnie

Views

6808

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

HardKnot OX 4x4

I've been working on commercial woodworking CNC's for year's under shop owner's that didn't want me to progress any further at a certain point. This is a project I've wanting to build for about 10 years now. I can't wait for the freedom to build what I know is possible without any negative input.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

Yamm (Yet another MiniMill)

First time CNC user having a good time with a MiniMill

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

My Shapeoko Router build

I built this as it is a small portable design.

Aluminium Router From Dubai

Another modification on the OX

My First CNC Machine

This will be a step by step record charting my successes and failures in my voyage of discovery while building a CNC router. Please excuse my English-English which may lose something in translation to American-English. I would be grateful for any advice during the build

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Build Author

Joerharris

Views

6571

Build Author

Joerharris

Views

6571

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

Hussein Dermay

Views

6525

Build Author

Hussein Dermay

Views

6525

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

Build Author

Zootalaws

Views

6479

Build Author

Zootalaws

Views

6479

OXENlarged

This is a 1500 x 1500 Ox build

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

My build

I am satisfied with my build and next one will be even better.

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

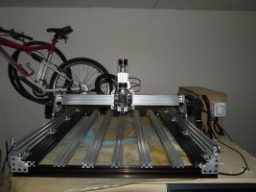

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Build Author

Karan Singh Sisodia

Views

6316

Build Author

Karan Singh Sisodia

Views

6316

My Home made CNC

Home Made CNC Router from Scrape

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

Camvec

Views

6278

Build Author

Camvec

Views

6278

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Large OX

A larger version of the OX.

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

Build Author

TurfnSurf

Views

6220

Build Author

TurfnSurf

Views

6220

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

inhan

Views

6214

Build Author

inhan

Views

6214

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Build Author

Gary Bonard

Views

6187

Build Author

Gary Bonard

Views

6187

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

msdosfx

Views

6170

Build Author

msdosfx

Views

6170

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.