Build List

Build Author

Yanou Fishel

Views

11417

Build Author

Yanou Fishel

Views

11417

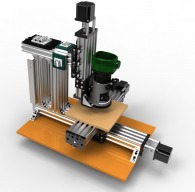

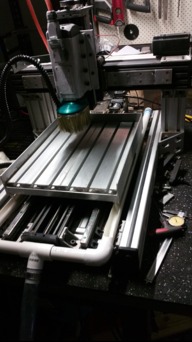

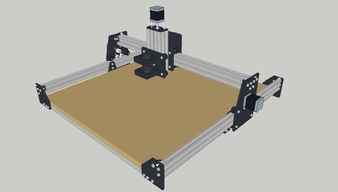

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

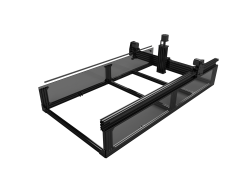

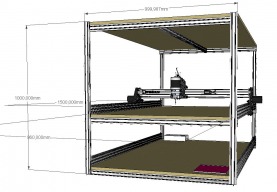

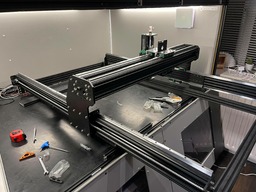

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

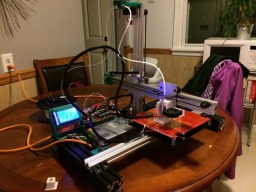

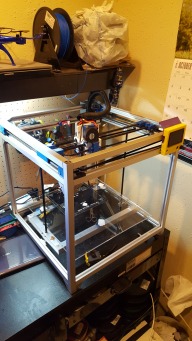

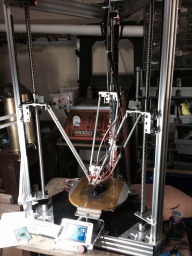

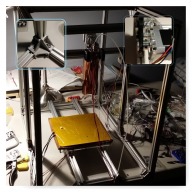

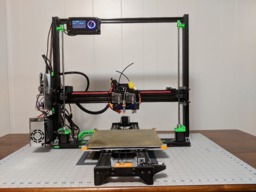

Ez3D - Phoenix 3D Printer Build

This is my 1st submission to openbuilds.com and my 1st venture into building a 3D Printer. The Phoenix 3d Printer is a kit from Ez3D, a company based out of Colorado, started and backed by successful Kick-starter and IndieGogo campaigns. The Phoenix 3d Printer kit is currently backlogged 10 to 12 weeks which means quite a wait. I will be chronicling my experience with this kit as I get it done.

Ooznest OX CNC Build

Ooznest OX CNC build

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

CraneBot

A minimum parts build with belt driven Z-axis.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

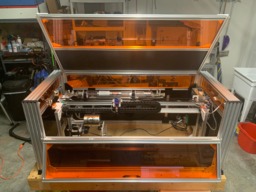

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

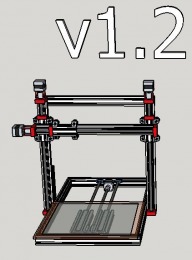

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

jjcolletta

Views

11217

Build Author

jjcolletta

Views

11217

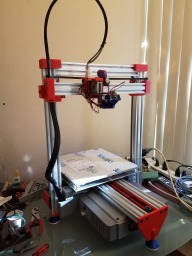

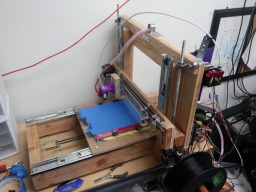

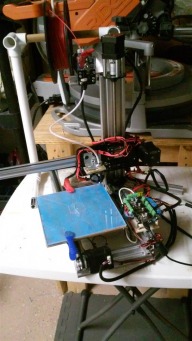

First 3d build

I am building a simple home brewed printer. I have a background in industrial automation so I figured how hard could this be. The mechanical build was pretty smooth as was the electrical side. Now just getting plastic out the hotend is my stopping point.

The Franken Rotor

Yes another K40 Franken machine dedicated for round objects,,,

SolidCore CoreXY

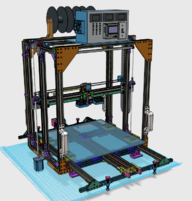

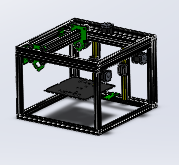

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Build Author

Mike Campbell

Views

11149

Build Author

Mike Campbell

Views

11149

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

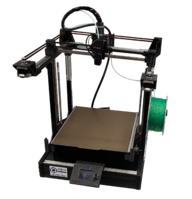

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

Bear

Views

11068

Build Author

Bear

Views

11068

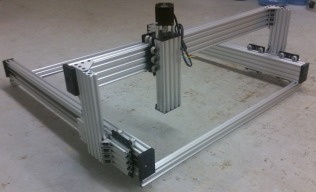

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

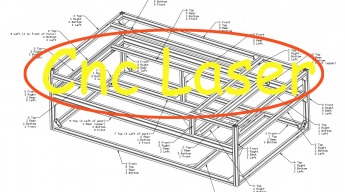

Laser cutter

In the expo projects during the second year of engineering students. the project group who made this rapport made a laser cutter for the students of Fontys Hogeschool Engineering to use this machine for creating parts for their projects. The goal of Project Laser Cutter is to build a laser cutter, which is safe and can be used within the school. Also it has to be able to cut through 10 millimetres thick acrylic material or 10 millimetres thick plywood. This project will follow the V-model. This

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

Build Author

J-Wahl Dezign

Views

11015

Build Author

J-Wahl Dezign

Views

11015

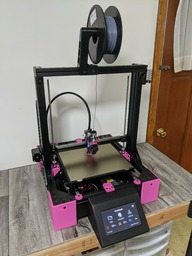

My little monster

Modified Tevo

Draw bot core xy

In the design stage. Help guide.

Build Author

Rob Taylor

Views

10985

Build Author

Rob Taylor

Views

10985

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

Laurence Carroll

Views

10976

Build Author

Laurence Carroll

Views

10976

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

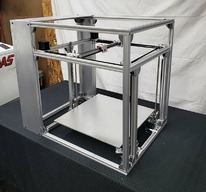

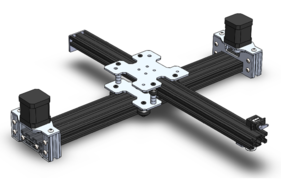

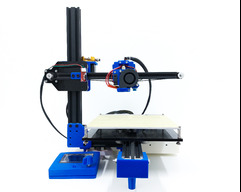

All Metal - CoreXY Motion

Stacked CoreXY Motion System using only Openbuilds components

Build Author

Steven Sampson

Views

10940

Build Author

Steven Sampson

Views

10940

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Dedicated Compact Rotary Axis Laser Engraver

Compact Dedicated Rotary Axis Laser Engraver

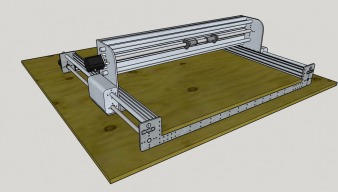

Long Ox with drop in table

This build is a modified Ox build. The long rails are 1000mm. My build includes a solid clamping table.

RoStockFAZZ

My large printer design. 400mm build plate, ~1000mm build height. Most of structure is 8020 but the sliders are V-Rail

Build Author

Sonny Lowe

Views

10872

Build Author

Sonny Lowe

Views

10872

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

Build Author

Naomi Wu

Views

10842

Build Author

Naomi Wu

Views

10842

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

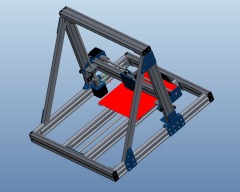

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

dcarlisle

Views

10771

Build Author

dcarlisle

Views

10771

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Build Author

jaron kennell

Views

10768

Build Author

jaron kennell

Views

10768

Rezo 1390 100W CO2 Laser

This laser is a beast. Designed by Jonathan Frost, and built with 45x45mm aluminum for ultimate rigidity. It has a 4'x3' bed with a pass through that can be utilized to cut full 8x4' sheets of plywood, and has a motorized bed. Rēzo is not only faster and more capable than lasers like Thunder Lasers Nova 51 and Aeon Nova 10, but the final build costs are 40-60% less than said commercially available machines. Plans can be found at https://rezo1390.bigcartel.com/product/rezo-1390-plans

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

Build Author

Keteland

Views

10717

Build Author

Keteland

Views

10717

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Darren Ditto

Views

10703

Build Author

Darren Ditto

Views

10703

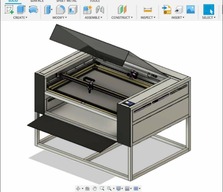

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Build Author

CNCGear

Views

10674

Build Author

CNCGear

Views

10674

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Yet Another Ox Build

This build log will chronicle the construction of my oversize (1000mm X 1500mm) OX router.

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Apple Crate CNC

Low cost, apple crate framed CNC.

Build Author

Kyo

Views

10617

Build Author

Kyo

Views

10617

Fina

This is Fina; My Lautr3k inspired build.

Open Rail Build

This will be a chronicle. It's my first CNC build so, I will be making many changes as I learn from my mistakes. I will pass on any tips or tricks i learn along the way. This build is an OX Hybrid. I decided to use the open rail with the V wheels and not to go with the V Slot. (I'll let you know how it works out.)

Build Author

UltiBots

Views

10579

Build Author

UltiBots

Views

10579

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

Makerparts.ca Prusa i3Pro 300

Concept for a Prusa i3 made from Cbeam Extrusion. X & Y using GT2 Belts, Z using Acme Screws Goal is to build a simple. and very Solid Printer Single Z Motor to keep the Z Screws in Sync. (Might require Geared Nema 17) 12" x 12" x 12" Build volume Nema 17's

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

Build Author

StrictlyScale

Views

10502

Build Author

StrictlyScale

Views

10502

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

Lasersc

Views

10477

Build Author

Lasersc

Views

10477

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

C-Beam bellows

Making a bellows to cover a C-beam to prevent swarf from gumming up the works.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

Build Author

Kaarbble

Views

10410

Build Author

Kaarbble

Views

10410

Kaarbble Nylon Bot

We plan experiment on nylon 3 D printing;

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China

TABLE OX Router/3D-Printer

OX MultiMachine

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Pendragon

Views

10330

Build Author

Pendragon

Views

10330

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Laseroko Laser Engraver Build

After expanding a Shapeoko 2 with the rails and motors left over, make yourself a laser engraver.

(Smaug) 100w 1500x1000mm CNC Laser

Laser CNC made with mostly Openbuilds and amazon sourced components. Lots of 3d printed components as well. The main purpose is to cut EVA foam.

Build Author

Superslinky

Views

10286

Build Author

Superslinky

Views

10286

K40 Laser Build (Major Changes)

Major K40 Laser Mod

Build Author

Larry_AK

Views

10285

Build Author

Larry_AK

Views

10285

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

BinaryConstruct

Views

10246

Build Author

BinaryConstruct

Views

10246

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Viking OX

My OX cnc upgrade.

Build Author

Mark Rehorst

Views

10198

Build Author

Mark Rehorst

Views

10198

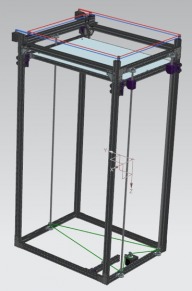

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

Build Author

Bob Darrow

Views

10162

Build Author

Bob Darrow

Views

10162

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

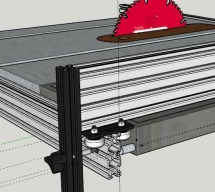

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

ALUMNO v1

It is a first draw of my future Printer/CNC cutter.PCB mill Still need to work more on it

Build Author

Philippe Bergeron

Views

10122

Build Author

Philippe Bergeron

Views

10122

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

Build Author

Kyo

Views

10122

Build Author

Kyo

Views

10122

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

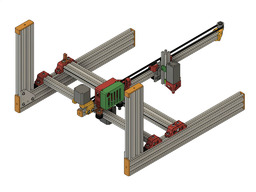

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Build Author

COMsulting

Views

10108

Build Author

COMsulting

Views

10108

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

Build Author

M1dn1ghtN1nj4

Views

10089

Build Author

M1dn1ghtN1nj4

Views

10089

The Beast

This is a heavily modified system based on the RatRig V-Cast. Lots of personal touches, and a LOT more to come!

Build Author

Robert Mech

Views

10079

Build Author

Robert Mech

Views

10079

LayerFused X301 - CoreXY Large Volume Printer

The X301 is a CoreXY 3D Printer that has a small footprint and a large 300x300x330 build area. The open style of this printer breaks the "Cube" mold of many other printers in this class but still retails rigidity and great performance.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

crypt-tek

Views

10059

Build Author

crypt-tek

Views

10059

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Build Author

pedrofernandez

Views

10047

Build Author

pedrofernandez

Views

10047

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

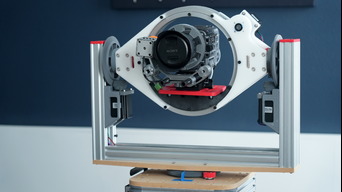

6 Axis Motion Control Camera Rig (PAN, TILT, ROLL, SLIDE, FOCUS, ZOOM)

6 axis rig based on OpenBuild C-Beam and ESP32 MCU, WiFi controlled with custom app.

Build Author

Christian James

Views

10026

Build Author

Christian James

Views

10026

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

Hydraulic lifting table

I started this project without drawing. in itself this went fine with some minor adjustments. My profession is machine builder that might make it a little easier. I still enjoy it every day.

Horizontal Cantilever or Vertical Diode Laser Engraver

Light weight portable Laser Engraver (6.5lbs - 12lbs)

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

Ahmed Ibrahim

Views

9945

Build Author

Ahmed Ibrahim

Views

9945

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

LayerFused C201 - DIY 3D Printer Build, i3 Style

My DIY 3D Printer build which is similar to an i3 style printer. This is a fully documented step-by-step build with videos.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

deltajegga

Views

9906

Build Author

deltajegga

Views

9906

THE delta

probably as big as you'd want it...

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

Build Author

Keith Davis

Views

9877

Build Author

Keith Davis

Views

9877

Upgrading Your 3D Printer With Synchronous Leveling

Upgrading printers for Synchronous Leveling

Build Author

Frank Gore

Views

9876

Build Author

Frank Gore

Views

9876

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.