Build List

-

Active Filters:

tr

Build Author

Scotty Orr

Views

11754

Build Author

Scotty Orr

Views

11754

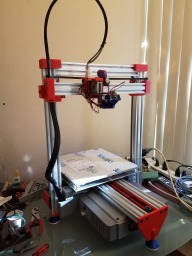

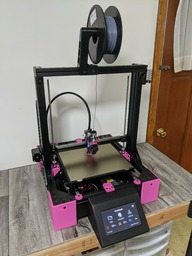

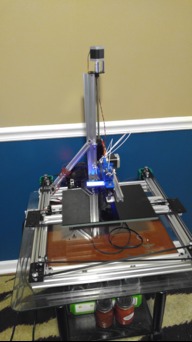

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

Build Author

David Florian

Views

11749

Build Author

David Florian

Views

11749

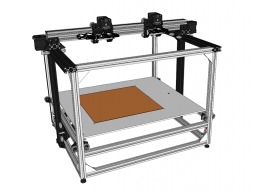

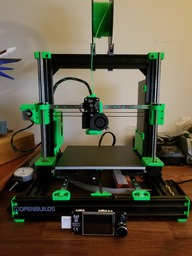

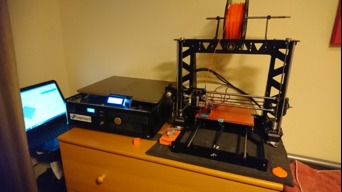

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

Glenn Weston

Views

11518

Build Author

Glenn Weston

Views

11518

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

Naomi Wu

Views

10883

Build Author

Naomi Wu

Views

10883

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Kyo

Views

10635

Build Author

Kyo

Views

10635

Fina

This is Fina; My Lautr3k inspired build.

Build Author

BinaryConstruct

Views

10269

Build Author

BinaryConstruct

Views

10269

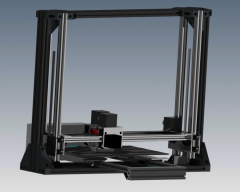

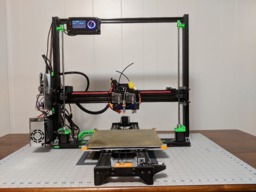

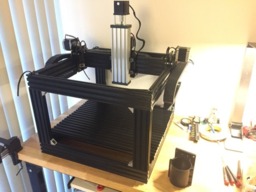

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

M1dn1ghtN1nj4

Views

10137

Build Author

M1dn1ghtN1nj4

Views

10137

The Beast

This is a heavily modified system based on the RatRig V-Cast. Lots of personal touches, and a LOT more to come!

Build Author

Christian James

Views

10093

Build Author

Christian James

Views

10093

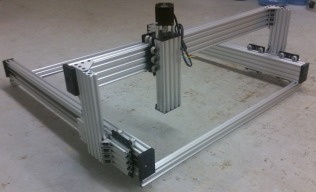

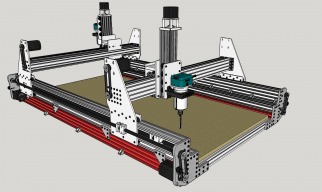

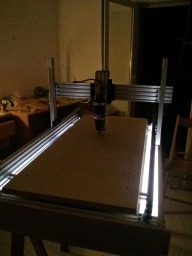

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

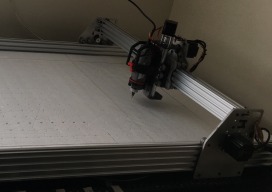

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Build Author

Michael.M

Views

9736

Build Author

Michael.M

Views

9736

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Nicademus

Views

9629

Build Author

Nicademus

Views

9629

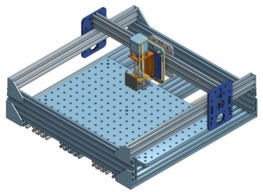

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Quentin Karmark

Views

9571

Build Author

Quentin Karmark

Views

9571

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Build Author

Christer Langley

Views

9485

Build Author

Christer Langley

Views

9485

CNC-Solutions Build

My first Build with V-slot

Build Author

Jesse Jenkins

Views

9451

Build Author

Jesse Jenkins

Views

9451

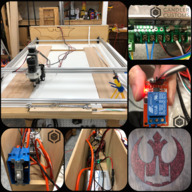

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Gooshpoo

Views

9386

Build Author

Gooshpoo

Views

9386

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

zann68

Views

9382

Build Author

zann68

Views

9382

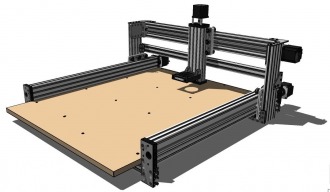

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Sergio Di Ventura

Views

9376

Build Author

Sergio Di Ventura

Views

9376

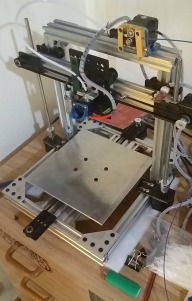

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

Pol Feliu

Views

9292

Build Author

Pol Feliu

Views

9292

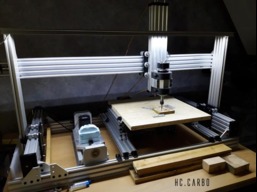

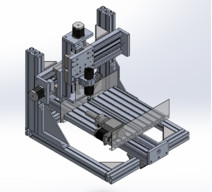

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

J-Wahl Dezign

Views

9171

Build Author

J-Wahl Dezign

Views

9171

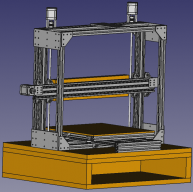

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

Lindsey Lewis

Views

9066

Build Author

Lindsey Lewis

Views

9066

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

Krishnakumar

Views

8818

Build Author

Krishnakumar

Views

8818

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

mikev

Views

8626

Build Author

mikev

Views

8626

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Build Author

Joe F

Views

8571

Build Author

Joe F

Views

8571

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

Kenneth Witthuhn

Views

8549

Build Author

Kenneth Witthuhn

Views

8549

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Build Author

John J Talavera

Views

8517

Build Author

John J Talavera

Views

8517

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Build Author

Carl van Heezik

Views

8507

Build Author

Carl van Heezik

Views

8507

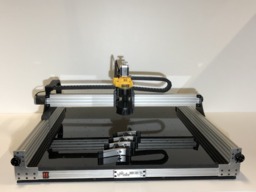

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

MikieLikesIt

Views

8284

Build Author

MikieLikesIt

Views

8284

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

Lindsey Lewis

Views

8266

Build Author

Lindsey Lewis

Views

8266

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

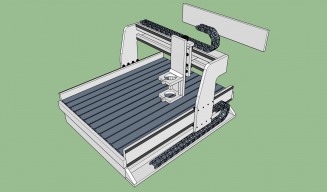

Sketchup Design of a PVC CNC I Intend to build.

Build Start to begin Feb 1st.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

Jay Almers

Views

8114

Build Author

Jay Almers

Views

8114

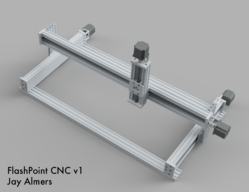

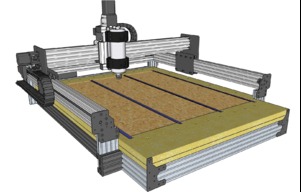

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Sam Dobbie

Views

7841

Build Author

Sam Dobbie

Views

7841

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

Build Author

OffAxis

Views

7801

Build Author

OffAxis

Views

7801

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

Carl Siren

Views

7696

Build Author

Carl Siren

Views

7696

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Butterfly 3DP V 1.0

tronxy x3 like

Build Author

MrMojoRisin

Views

7644

Build Author

MrMojoRisin

Views

7644

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

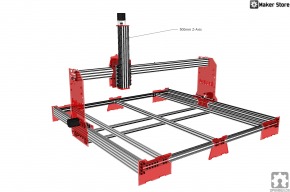

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

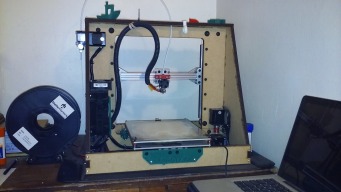

Panther Printer - Lautr3k

My version of the popular Lautr3k 3D printer. UNI Panther colors of Purple and Yellow on black V-slot rails. 300x300 bed.

Build Author

Peter Van Der Walt

Views

7502

Build Author

Peter Van Der Walt

Views

7502

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

Tom Dirriwachter

Views

7407

Build Author

Tom Dirriwachter

Views

7407

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

mirage335

Views

7403

Build Author

mirage335

Views

7403

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Build Author

evgeny156

Views

7368

Build Author

evgeny156

Views

7368

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

James Evanko

Views

7355

Build Author

James Evanko

Views

7355

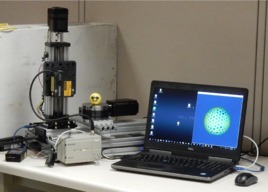

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

Build Author

TurfnSurf

Views

7177

Build Author

TurfnSurf

Views

7177

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

Tommy Williamson

Views

7096

Build Author

Tommy Williamson

Views

7096

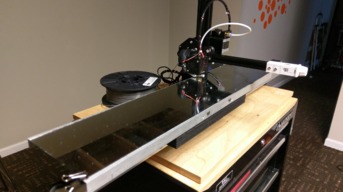

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Jose A. Molina

Views

7057

Build Author

Jose A. Molina

Views

7057

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

Build Author

Fabio Orsi

Views

6973

Build Author

Fabio Orsi

Views

6973

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Build Author

rkugler

Views

6927

Build Author

rkugler

Views

6927

Miter Saw Stop Block

Just starting a miter saw stop system. Any suggestions appreciated.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Build Author

thehans

Views

6702

Build Author

thehans

Views

6702

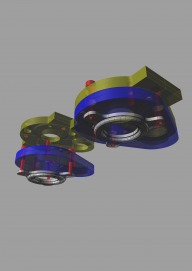

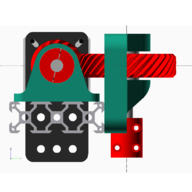

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

dodgenet

Views

6626

Build Author

dodgenet

Views

6626

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

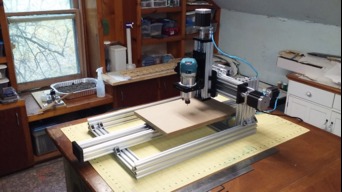

My First CNC Machine

This will be a step by step record charting my successes and failures in my voyage of discovery while building a CNC router. Please excuse my English-English which may lose something in translation to American-English. I would be grateful for any advice during the build

Build Author

crystaldragon141

Views

6604

Build Author

crystaldragon141

Views

6604

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Build Author

Hussein Dermay

Views

6570

Build Author

Hussein Dermay

Views

6570

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Build Author

mytechno3d

Views

6516

Build Author

mytechno3d

Views

6516

DSLR ( video ) motorized slider

In order to make some nice traveling video you need a slider .

Build Author

Terone Burgenheim

Views

6495

Build Author

Terone Burgenheim

Views

6495

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Zootalaws

Views

6494

Build Author

Zootalaws

Views

6494

OXENlarged

This is a 1500 x 1500 Ox build

Build Author

Connor Mckeown

Views

6453

Build Author

Connor Mckeown

Views

6453

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Blyn3D

Views

6441

Build Author

Blyn3D

Views

6441

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

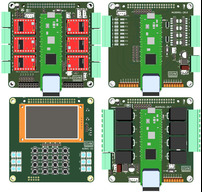

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Build Author

Camvec

Views

6313

Build Author

Camvec

Views

6313

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

Build Author

TurfnSurf

Views

6248

Build Author

TurfnSurf

Views

6248

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

Mark Carew

Views

6219

Build Author

Mark Carew

Views

6219

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Gary Bonard

Views

6205

Build Author

Gary Bonard

Views

6205

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

David E. Flores E.

Views

6201

Build Author

David E. Flores E.

Views

6201

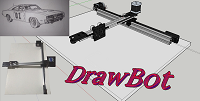

DaveWare DrawBot

Turning my prototypes into real objects, it will be required a great amount of drawings, A LOT. Therefore, against the ink costs raise price push me to think in a way to draw models, blueprints, etc. at very, VERY low cost. This is where my DrawBot was born

Build Author

RJ_Make

Views

6142

Build Author

RJ_Make

Views

6142

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

JAC_101

Views

6111

Build Author

JAC_101

Views

6111

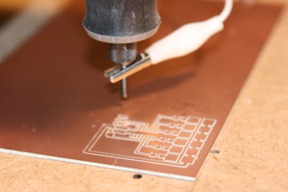

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Build Author

Jacob Lotter

Views

6072

Build Author

Jacob Lotter

Views

6072

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Build Author

OpenBuilds

Views

5995

Build Author

OpenBuilds

Views

5995

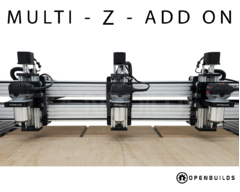

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Build Author

Joe Young

Views

5959

Build Author

Joe Young

Views

5959

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

Luke Cunningham

Views

5931

Build Author

Luke Cunningham

Views

5931

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Double trolley X and Z belt training

Total belt drive GT2

Dust Boot and Holddown in one

only 2 screws to hold down even bent sheet material and vaccum dust removal in one

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5845

Build Author

Sam Price

Views

5845

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Paul Amelang

Views

5818

Build Author

Paul Amelang

Views

5818

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

Build Author

h3rb

Views

5802

Build Author

h3rb

Views

5802

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

ZacharyB

Views

5790

Build Author

ZacharyB

Views

5790

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

spark2

Views

5731

Build Author

spark2

Views

5731

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

Todd Brous

Views

5729

Build Author

Todd Brous

Views

5729

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

Build Author

Cortellini

Views

5641

Build Author

Cortellini

Views

5641

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Build Author

ajdubs

Views

5635

Build Author

ajdubs

Views

5635

A custom arcade

This is an arcade "cabinet" of sorts built almost entirely from OpenBuilds extrusions. Save for a few 3d printed parts, the electrical components, the acrylic panels, and the monitor mount, every component was purchased from the OpenBuilds part store.

Build Author

CandlerCustoms

Views

5604

Build Author

CandlerCustoms

Views

5604

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

C_Beam Hammerhead 5x

setup for learning 5x

Build Author

3D Meister

Views

5573

Build Author

3D Meister

Views

5573

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.