Build List

-

Active Filters:

r

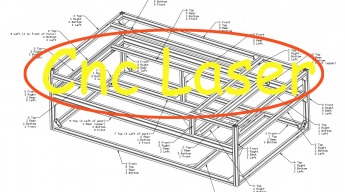

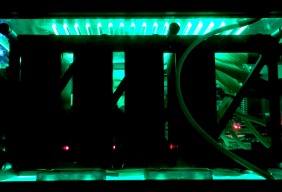

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

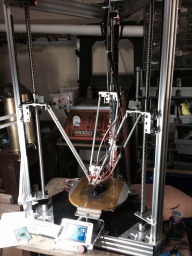

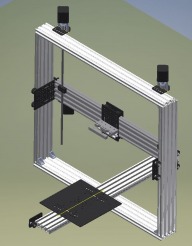

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China

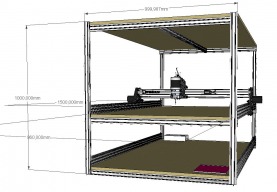

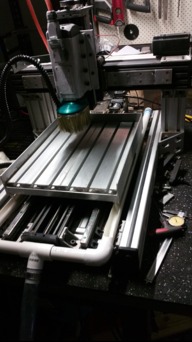

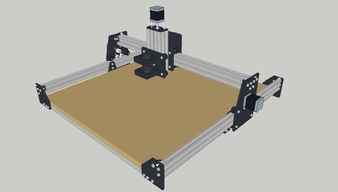

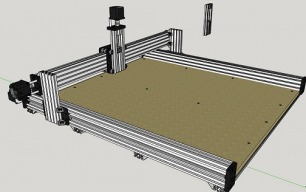

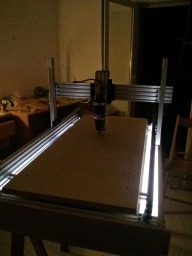

TABLE OX Router/3D-Printer

OX MultiMachine

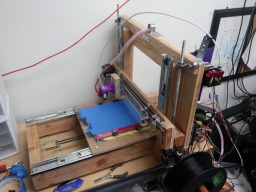

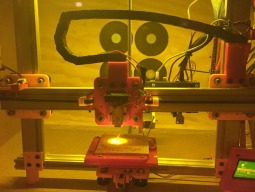

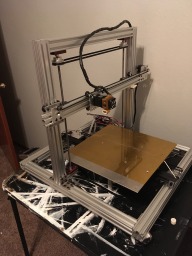

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Pendragon

Views

10326

Build Author

Pendragon

Views

10326

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Laseroko Laser Engraver Build

After expanding a Shapeoko 2 with the rails and motors left over, make yourself a laser engraver.

(Smaug) 100w 1500x1000mm CNC Laser

Laser CNC made with mostly Openbuilds and amazon sourced components. Lots of 3d printed components as well. The main purpose is to cut EVA foam.

Build Author

Larry_AK

Views

10283

Build Author

Larry_AK

Views

10283

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

Build Author

Superslinky

Views

10280

Build Author

Superslinky

Views

10280

K40 Laser Build (Major Changes)

Major K40 Laser Mod

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

BinaryConstruct

Views

10245

Build Author

BinaryConstruct

Views

10245

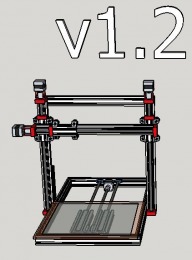

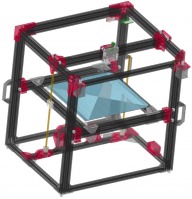

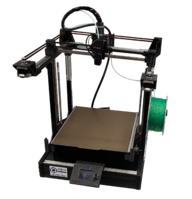

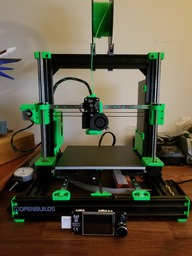

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Mark Rehorst

Views

10196

Build Author

Mark Rehorst

Views

10196

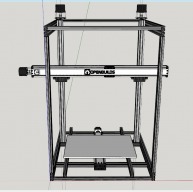

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

Build Author

Bob Darrow

Views

10155

Build Author

Bob Darrow

Views

10155

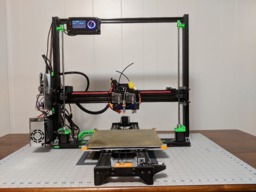

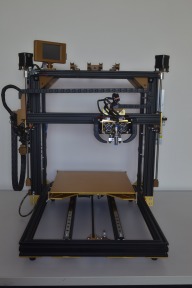

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

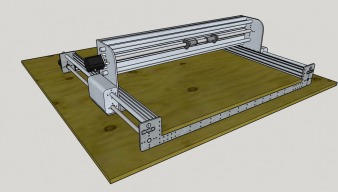

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

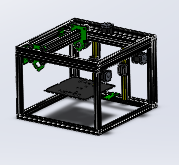

ALUMNO v1

It is a first draw of my future Printer/CNC cutter.PCB mill Still need to work more on it

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Philippe Bergeron

Views

10121

Build Author

Philippe Bergeron

Views

10121

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

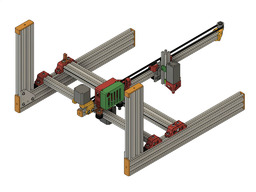

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Build Author

Kyo

Views

10108

Build Author

Kyo

Views

10108

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

COMsulting

Views

10106

Build Author

COMsulting

Views

10106

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

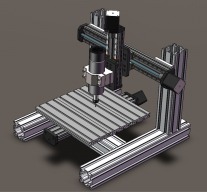

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

Build Author

M1dn1ghtN1nj4

Views

10080

Build Author

M1dn1ghtN1nj4

Views

10080

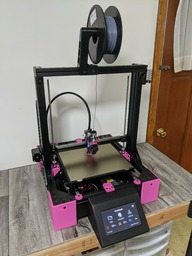

The Beast

This is a heavily modified system based on the RatRig V-Cast. Lots of personal touches, and a LOT more to come!

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

Robert Mech

Views

10073

Build Author

Robert Mech

Views

10073

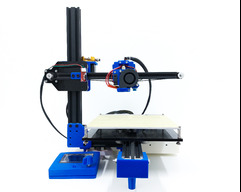

LayerFused X301 - CoreXY Large Volume Printer

The X301 is a CoreXY 3D Printer that has a small footprint and a large 300x300x330 build area. The open style of this printer breaks the "Cube" mold of many other printers in this class but still retails rigidity and great performance.

Build Author

crypt-tek

Views

10057

Build Author

crypt-tek

Views

10057

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Build Author

pedrofernandez

Views

10044

Build Author

pedrofernandez

Views

10044

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

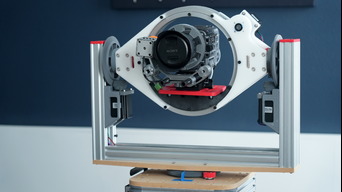

6 Axis Motion Control Camera Rig (PAN, TILT, ROLL, SLIDE, FOCUS, ZOOM)

6 axis rig based on OpenBuild C-Beam and ESP32 MCU, WiFi controlled with custom app.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

Build Author

Christian James

Views

10005

Build Author

Christian James

Views

10005

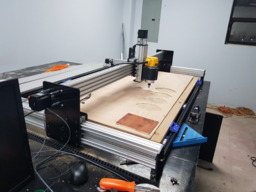

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Hydraulic lifting table

I started this project without drawing. in itself this went fine with some minor adjustments. My profession is machine builder that might make it a little easier. I still enjoy it every day.

Horizontal Cantilever or Vertical Diode Laser Engraver

Light weight portable Laser Engraver (6.5lbs - 12lbs)

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

Ahmed Ibrahim

Views

9938

Build Author

Ahmed Ibrahim

Views

9938

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

LayerFused C201 - DIY 3D Printer Build, i3 Style

My DIY 3D Printer build which is similar to an i3 style printer. This is a fully documented step-by-step build with videos.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

deltajegga

Views

9902

Build Author

deltajegga

Views

9902

THE delta

probably as big as you'd want it...

Build Author

Keith Davis

Views

9872

Build Author

Keith Davis

Views

9872

Upgrading Your 3D Printer With Synchronous Leveling

Upgrading printers for Synchronous Leveling

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

Build Author

Frank Gore

Views

9870

Build Author

Frank Gore

Views

9870

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Voxel OX Based Build

Building upon the great work done by Marshall Peck and others. I have started a new build.

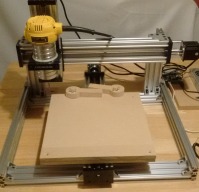

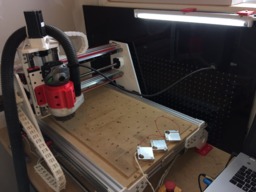

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Ike:Laser

A 2 axis laser engraving machine, with a manual Z axis.

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

Build Author

Frank Del Favero

Views

9750

Build Author

Frank Del Favero

Views

9750

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Pelican Case 3D Printer

A portable 3D Printer that can flat pack into a hard carry case

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

Michael.M

Views

9696

Build Author

Michael.M

Views

9696

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

Asaku

Views

9663

Build Author

Asaku

Views

9663

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Build Author

mathom713

Views

9632

Build Author

mathom713

Views

9632

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

ACRO 150 X 150 CM

Openbuilds ACRO

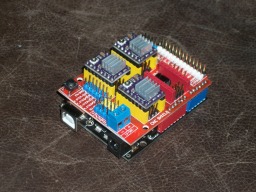

Controll Board for CNC Projects

The Echinus Team change the Firmware from "Teacup" to "Marlin". I use this board in my 3D Printer and it works very good! So I write a short report.

Build Author

Nicademus

Views

9585

Build Author

Nicademus

Views

9585

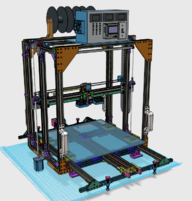

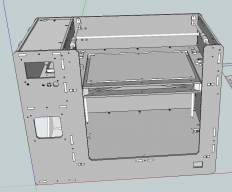

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

OX

My build of the OX kit from SMW3D.com

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

Maxime Favre

Views

9537

Build Author

Maxime Favre

Views

9537

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

CreativeTools

Views

9536

Build Author

CreativeTools

Views

9536

Universal stand-alone filament spool holder (Fully 3D-printable)

A practical rotating and stand-alone spool holder which fits any filament extrusion 3D-printer. Several base files provided which make it fit different extruded aluminium profiles.

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Delta without vertices

As this is a build in progress, I will update it as I progress.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Quentin Karmark

Views

9467

Build Author

Quentin Karmark

Views

9467

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

Christer Langley

Views

9460

Build Author

Christer Langley

Views

9460

CNC-Solutions Build

My first Build with V-slot

Kool Bot

Mid range build.

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

Build Author

Colin Russon

Views

9443

Build Author

Colin Russon

Views

9443

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

Jesse Jenkins

Views

9423

Build Author

Jesse Jenkins

Views

9423

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Rwetzler

Views

9391

Build Author

Rwetzler

Views

9391

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

Build Author

Gooshpoo

Views

9352

Build Author

Gooshpoo

Views

9352

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

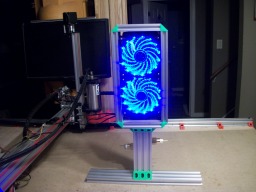

Spindle cooling setup

Cooling system for water cooled spindle.

Build Author

Sergio Di Ventura

Views

9342

Build Author

Sergio Di Ventura

Views

9342

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

zann68

Views

9329

Build Author

zann68

Views

9329

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Huub65

Views

9317

Build Author

Huub65

Views

9317

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

recoush

Views

9313

Build Author

recoush

Views

9313

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

New 2 watt laser platform

Acro based 2 watt laser platform

Build Author

openhardwarecoza

Views

9304

Build Author

openhardwarecoza

Views

9304

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Build Author

Mike Andrews

Views

9300

Build Author

Mike Andrews

Views

9300

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

griso

Views

9279

Build Author

griso

Views

9279

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Build Author

Pol Feliu

Views

9277

Build Author

Pol Feliu

Views

9277

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

HuguesP

Views

9266

Build Author

HuguesP

Views

9266

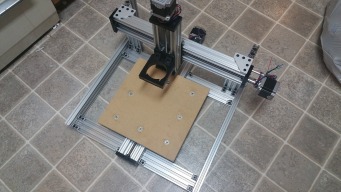

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Build Author

Bridge Port

Views

9263

Build Author

Bridge Port

Views

9263

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

HIGH POWER DC MOSFET (Relay)

High Power DC MOSFET

Build Author

Mark Carew

Views

9241

Build Author

Mark Carew

Views

9241

Work Bench Stand

Here is a nice little simple build that will help to free up some extra space on your work bench. If your like me you need all the room on your work station you can use, so this is great to have.

Build Author

Justin Butler

Views

9240

Build Author

Justin Butler

Views

9240

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

Build Author

Greg Lampman

Views

9238

Build Author

Greg Lampman

Views

9238

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

Build Author

J-Wahl Dezign

Views

9154

Build Author

J-Wahl Dezign

Views

9154

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.