Build List

-

Active Filters:

or

Build Author

Apothus

Views

22537

Build Author

Apothus

Views

22537

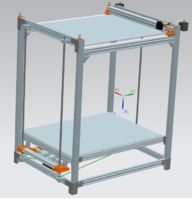

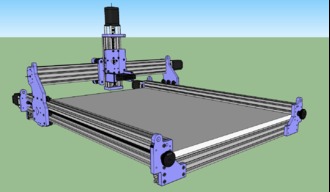

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

Roy Berntsen

Views

27254

Build Author

Roy Berntsen

Views

27254

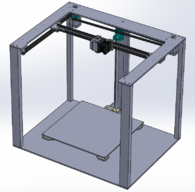

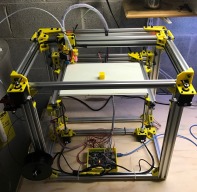

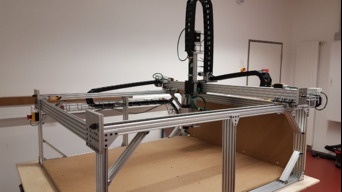

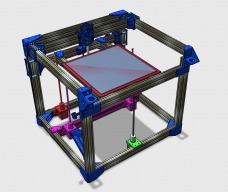

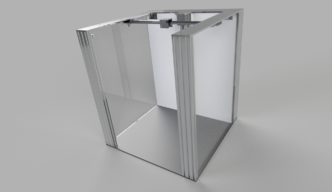

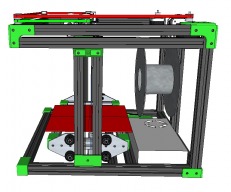

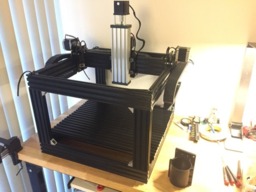

V-King CoreXY

V-King CoreXY 3d Printer- 380*340*340 Build volume - All wheels on V-Slots - Belts on XYZ - High quality and controlled design - Proven fast, reliable and it is all open source

Build Author

Rat Rig

Views

31722

Build Author

Rat Rig

Views

31722

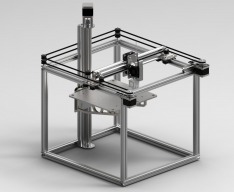

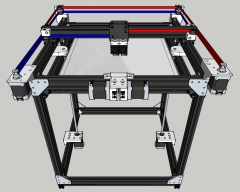

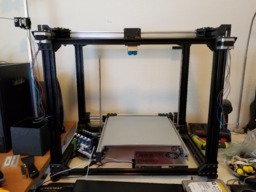

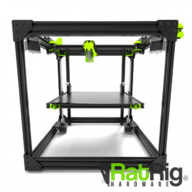

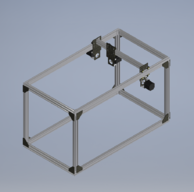

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

SCoreXY

Currently I have Velleman/3Drag K8200 modified and CNC machine self built and wanted to use both to make new 3D printer. After looking at different designs I liked Voron a lot and have decided to go that way. Currently I have ordered majority of parts and build shall start soon. I don't plan to rush it as I am usually 2 months home and 2 off. Today done some electronics. Looks ok. https://youtu.be/ls_tl54ruE0

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

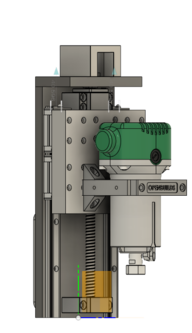

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

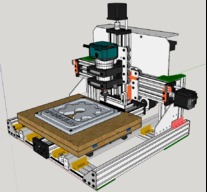

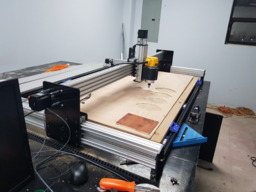

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Build Author

OpenBuilds

Views

6772

Build Author

OpenBuilds

Views

6772

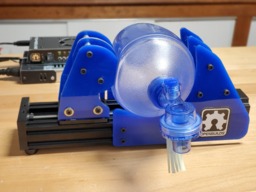

V-Slot Ventilator

The idea is to make a simple effective ventilator, studying the concept of using a simple push process with and actuator.

Angle grinder converted into electric drill

How to convert an angle grinder into an electric drill? Remove the angle grinder, leaving only one main motor, and then find a suitable intermediate roller with a point drill to assemble it.

V-Baby CoreXY - Quality Engineered DIY 3d Printer

Easy to build - affordable opensource DIY CoreXY 3d Printer for fast reliable prototyping on your desktop - All wheels and V-Slots for smooth quick moves and opensource firmware on 8 or 32 bit controllers

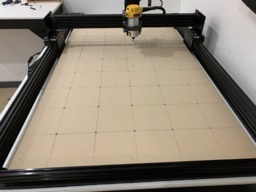

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Build Author

Tristen Poliseno

Views

4330

Build Author

Tristen Poliseno

Views

4330

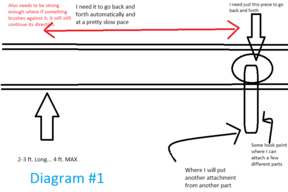

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

MIT E-Vent | MIT Emergency Ventilator

Ventilator prototype based of OpenBuilds Stock parts

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Build Author

Carl Feniak

Views

284994

Build Author

Carl Feniak

Views

284994

C-Bot

A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy.

Build Author

jeff johnson

Views

5785

Build Author

jeff johnson

Views

5785

workbee 1510

Getting more height out of the !510

Build Author

Forestbird Originals

Views

5521

Build Author

Forestbird Originals

Views

5521

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

Core XY Beast

Super solid core xy build inspired by the e3d tool changer

TesseractXY (MendelMax 1.5 version)

History about making 3d printer.

Workbee 1010

Hey all looking forward to sharing this build, I’ve learned a lot reviewing many of these great builds.

Build Author

DaleShaw

Views

4504

Build Author

DaleShaw

Views

4504

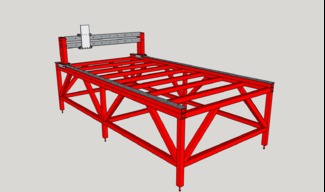

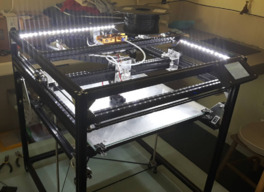

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

Build Author

David Florian

Views

11705

Build Author

David Florian

Views

11705

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

My Workbee build

Workbee, 1000mmX750mm , from China

Build Author

Vunnie

Views

6823

Build Author

Vunnie

Views

6823

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Build Author

Fábio Pires

Views

7077

Build Author

Fábio Pires

Views

7077

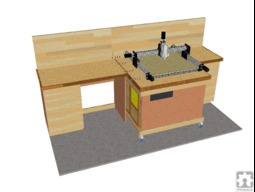

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Build Author

megashub

Views

24361

Build Author

megashub

Views

24361

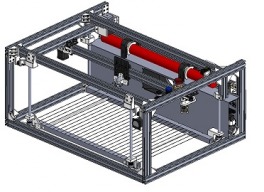

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Mark Carew

Views

93215

Build Author

Mark Carew

Views

93215

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

Build Author

Mark Carew

Views

28247

Build Author

Mark Carew

Views

28247

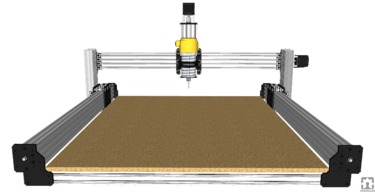

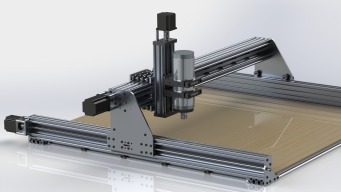

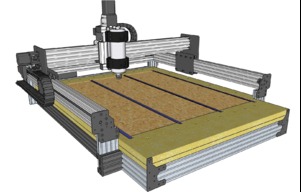

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Build Author

j0achim

Views

12371

Build Author

j0achim

Views

12371

CoreXY - e3d inspired

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Build Author

Craig Hollabaugh

Views

4930

Build Author

Craig Hollabaugh

Views

4930

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

rkugler

Views

6913

Build Author

rkugler

Views

6913

Miter Saw Stop Block

Just starting a miter saw stop system. Any suggestions appreciated.

Build Author

reef

Views

12073

Build Author

reef

Views

12073

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

recoush

Views

9340

Build Author

recoush

Views

9340

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

Build Author

Sir Bagels

Views

3138

Build Author

Sir Bagels

Views

3138

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

H-Bot CoreXY Cube

Dead build.

Build Author

James Evanko

Views

7336

Build Author

James Evanko

Views

7336

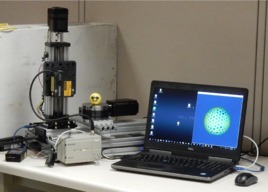

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

msdosfx

Views

6191

Build Author

msdosfx

Views

6191

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

Build Author

CoreCube3D

Views

22131

Build Author

CoreCube3D

Views

22131

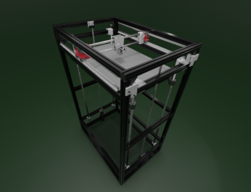

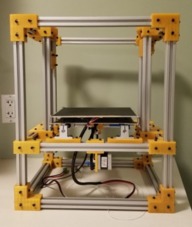

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

KeePrint Monster

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.

Mushu - Large Scale CoreXY

20x26x28 inch Build Volume CoreXY. Unlike many builds, I've decoupled the XY movements from the Z-Axis lead screws to help prevent Wobble, will be using linear guide rails, and mains powered bed heater, and a bed that is Allowed to thermally grow. This build is JUST narrow enough to fit through a standard sized doorway.

Build Author

KronBjorn

Views

4486

Build Author

KronBjorn

Views

4486

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Build Author

RobFromLDMS

Views

5291

Build Author

RobFromLDMS

Views

5291

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

RV6APilot

Views

4252

Build Author

RV6APilot

Views

4252

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

Stan Howe

Views

3371

Build Author

Stan Howe

Views

3371

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

Keith Davis

Views

20754

Build Author

Keith Davis

Views

20754

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

John J Talavera

Views

18735

Build Author

John J Talavera

Views

18735

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

Build Author

crystaldragon141

Views

6593

Build Author

crystaldragon141

Views

6593

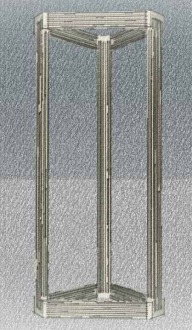

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Kraken Core-XY Printer

Core-XY build witha quad nozzle

Build Author

Bikes and Beer

Views

4901

Build Author

Bikes and Beer

Views

4901

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Build Author

thinman

Views

8839

Build Author

thinman

Views

8839

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

Build Author

Cosmosteel

Views

4597

Build Author

Cosmosteel

Views

4597

Clear Acrylic Dust Shoe

Attaches router with screw clamping. Clear Skirt is 2" long or can be made longer if requested. Works well keeping dust within the chamber. It can be made to fit shapeoko, ox cnc, workbee, xcarve, 6040, laguna,piranha, millright etc. with similar setup including Bosh, Makita , dewalt 611 routers or spindles.

Build Author

CharlieShimota

Views

16260

Build Author

CharlieShimota

Views

16260

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

Build Author

Hidro669

Views

3795

Build Author

Hidro669

Views

3795

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Build Author

Vegard Humlen

Views

5054

Build Author

Vegard Humlen

Views

5054

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

OoozNest WorkBee

A Journey on the WorkBee Build...

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Build Author

Christian James

Views

10066

Build Author

Christian James

Views

10066

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

John Bolduc

Views

5987

Build Author

John Bolduc

Views

5987

SG Duet Delta

This my version of a large no corners cut Delta.

Build Author

Joe Young

Views

5948

Build Author

Joe Young

Views

5948

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

Doug Rowley

Views

4356

Build Author

Doug Rowley

Views

4356

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

Rob Taylor

Views

20393

Build Author

Rob Taylor

Views

20393

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

Lumberjack Engineering

Views

20234

Build Author

Lumberjack Engineering

Views

20234

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Build Author

Eric Jacobsson

Views

15472

Build Author

Eric Jacobsson

Views

15472

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

Liam Dahler

Views

6560

Build Author

Liam Dahler

Views

6560

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Build Author

ChrisViral

Views

7189

Build Author

ChrisViral

Views

7189

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

James Evanko

Views

4126

Build Author

James Evanko

Views

4126

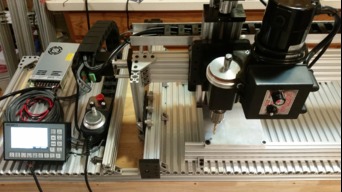

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Build Author

James Evanko

Views

4875

Build Author

James Evanko

Views

4875

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

SCYBUCK

Views

5146

Build Author

SCYBUCK

Views

5146

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Kyo

Views

6548

Build Author

Kyo

Views

6548

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

stepper

Views

4566

Build Author

stepper

Views

4566

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

Build Author

Carl Siren

Views

7683

Build Author

Carl Siren

Views

7683

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Mark Rehorst

Views

10207

Build Author

Mark Rehorst

Views

10207

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Gary Caruso

Views

24953

Build Author

Gary Caruso

Views

24953

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

DPR-v2 full metal

pictures and mony doku see later

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Build Author

Hussein Dermay

Views

6549

Build Author

Hussein Dermay

Views

6549

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

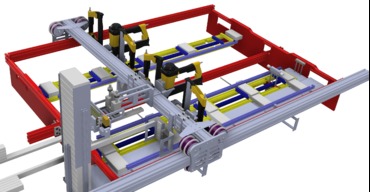

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

Axnfell

Views

3123

Build Author

Axnfell

Views

3123

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...