Build List

-

Active Filters:

r

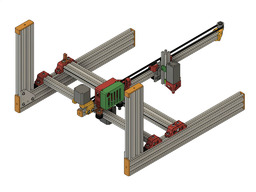

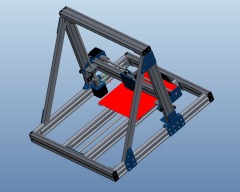

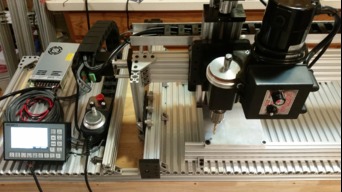

PROTODERA 5-axis CNC machine

We are a team representing private industry and public university all concerned about community. In the place i'm from we face problems related to prototyping industry, there's no accesibility to it, not because there is not machines to work with but the costs are really high if i want to make a single piece of any idea in order to develop a concept, our students get their degree but never were able to try any of the Hass or 3d systems machines available as it seems they need a PhD.

Adamantine

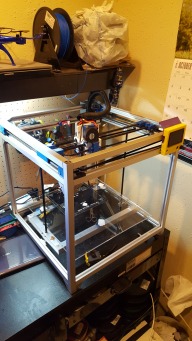

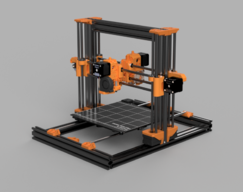

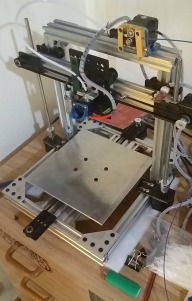

This is Adamantine, a all aluminum lead screw driven 3d printer. I wanted to have a printer that would not be effected by the heat or humidity I have here as my current wood frame printer is.

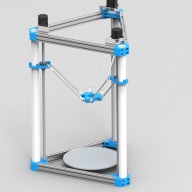

Delta 3d Printer

I am going to use this as a build log for my delta 3d printer build. I have access to a MakerBOT to print some of the parts. I am still finishing up a few of the design elements but the idea is to have a rigid unit to eliminate deflection in components and maintain accuracy.

Build Author

TomH

Views

16271

Build Author

TomH

Views

16271

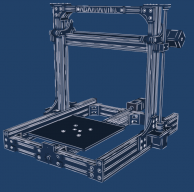

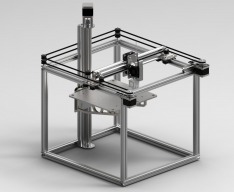

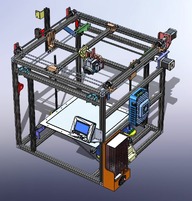

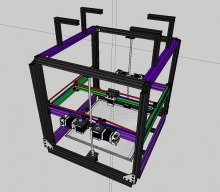

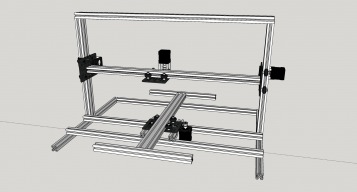

H-Bot CoreXY Cube with Fixed Build Plate

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

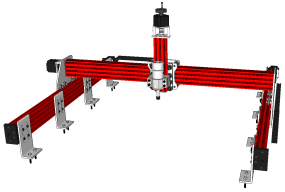

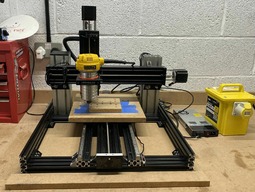

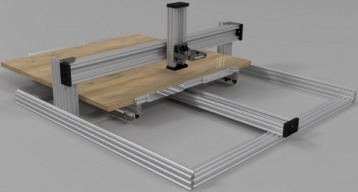

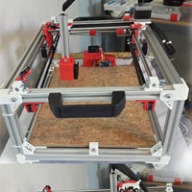

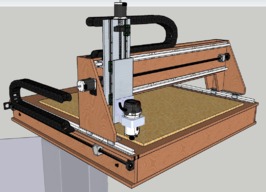

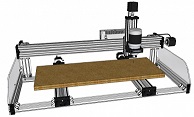

Screaming Ox CNC Machine

Big brother of the Charging Ox CNC machine.

Build Author

Kyo

Views

12451

Build Author

Kyo

Views

12451

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

k nest

This Build Is Is Inspired By OOZ Nest CNC, But With Some Changes,

Build Author

Robert Bailey

Views

29303

Build Author

Robert Bailey

Views

29303

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

zelos

Views

19151

Build Author

zelos

Views

19151

ZelosLaser Engraver/Cutter 2.0 : Sturdy & Versatile

Zelos Laser Cutter Version 2.0 GRBL Shield with Nema 17 motors. 2 Watt laser for cutting and fine grayscale pictures built very sturdy and modular

Build Author

Steven Sampson

Views

10865

Build Author

Steven Sampson

Views

10865

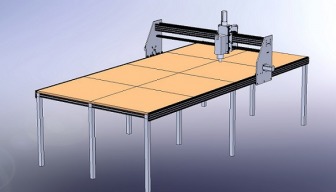

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

JCPhlux

Views

26360

Build Author

JCPhlux

Views

26360

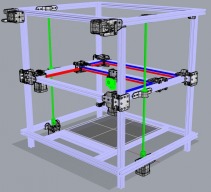

Tesseract

Large Core XY 3d Printer W/fixed build plate

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

Build Author

Dave420

Views

14550

Build Author

Dave420

Views

14550

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

Build Author

Rwetzler

Views

9277

Build Author

Rwetzler

Views

9277

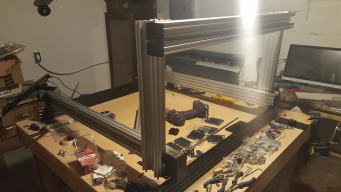

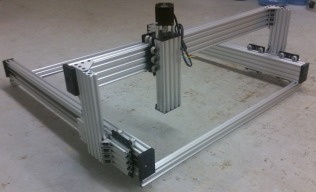

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

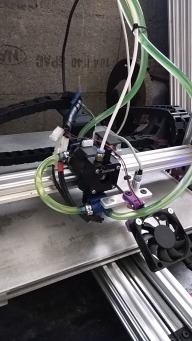

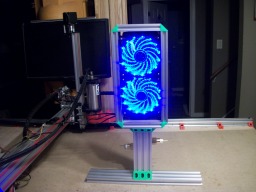

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

TesseractXY (MendelMax 1.5 version)

History about making 3d printer.

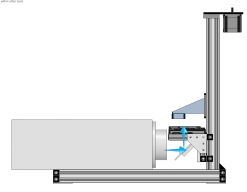

Spindle cooling setup

Cooling system for water cooled spindle.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Build Author

Venturebit

Views

13579

Build Author

Venturebit

Views

13579

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Build Author

JP Warnke

Views

12720

Build Author

JP Warnke

Views

12720

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Huub65

Views

9138

Build Author

Huub65

Views

9138

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

Beam

Views

11427

Build Author

Beam

Views

11427

DIY Flywheel Camera Slider

My take on a non affordable slider.

Miter Saw Station

A Miter Saw station built using a Dewalt Miter Saw Stand and V-Slot extrusions.

Build Author

DaveStewart

Views

6016

Build Author

DaveStewart

Views

6016

Small C-Beam Plate Maker With Remote Login & Operation

C-Beam Plate cutter with Raspberry Pi V3, Arduino Mega2560 and Camera. Remote login & operation via SSH with cnc.js server, mjpg server on the Pi.

Brokkr CNC 2.0

1M C-beam xy variant

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Nicademus

Views

9451

Build Author

Nicademus

Views

9451

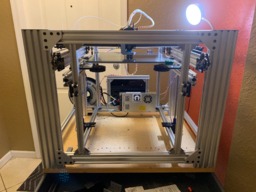

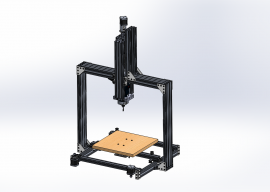

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

TurfnSurf

Views

7048

Build Author

TurfnSurf

Views

7048

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Big CNC plasma cutter

more later

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

Kevr102

Views

5733

Build Author

Kevr102

Views

5733

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

JerwanDavis

Views

6019

Build Author

JerwanDavis

Views

6019

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

James Evanko

Views

4026

Build Author

James Evanko

Views

4026

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Build Author

Bikes and Beer

Views

4775

Build Author

Bikes and Beer

Views

4775

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Jacob Lotter

Views

5860

Build Author

Jacob Lotter

Views

5860

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

Build Author

Project Hopeless

Views

14304

Build Author

Project Hopeless

Views

14304

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

Build Author

mathom713

Views

9556

Build Author

mathom713

Views

9556

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

Build Author

Martin.Barfoed

Views

6910

Build Author

Martin.Barfoed

Views

6910

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

txcomp

Views

6755

Build Author

txcomp

Views

6755

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

Troy Joachim

Views

18213

Build Author

Troy Joachim

Views

18213

Prusa i3 Bear IDEX

Remix of the Prusa i3 Bear with added IDEX

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Build Author

Yanou Fishel

Views

11199

Build Author

Yanou Fishel

Views

11199

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Build Author

OpenBuilds

Views

33746

Build Author

OpenBuilds

Views

33746

OpenBuilds Enclosure Series

Easy to build series of enclosures for all your CNC needs!

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

Build Author

Quentin Karmark

Views

9178

Build Author

Quentin Karmark

Views

9178

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Horizontal Cantilever or Vertical Diode Laser Engraver

Light weight portable Laser Engraver (6.5lbs - 12lbs)

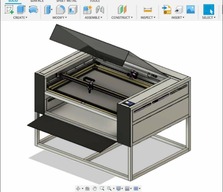

Custom 40W Laser Cutter

So this is my custom 40W build. I wanted to make another laser similar to the one I built but a lot smaller and an all in one system so that if I ever decide to do a farmers market or something similar, I wanted to be able to put the laser on the back of the car and drive to whatever location. I think it's going to work. It will be see-through with lights and screens eveywhere. The lights alone should attract people like flies. That's the plan anyway.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Dash X Direct, Cross-Beam 3d Printer

This is the next version of Dash, now operating much closer to its potential. Please message me if you need anything, such as Simplify3D settings, material information, design intent etc. Since the Pack-and-Go zip file is fairly large (120mB), here is a link where it can be downloaded: https://drive.google.com/file/d/1Q3ygyo_tTrB4UYIV62_wtCSCbWuE3krT/view?usp=sharing Note: I use Solidworks 2022, acquired through their Solidworks for Makers program (check it out!). A super deal at $100/yr

Build Author

Shaun Weitzel

Views

7243

Build Author

Shaun Weitzel

Views

7243

OpenBuilds Lead 1515

First build of a Lead 1515!

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Sphinx 66

A Sphinx Linear rail build (600mm x 600mm) hence the title Sphinx66. Plates supplied by Chris Laidlaw. Linear rails used MGN15

Build Author

jaron kennell

Views

10269

Build Author

jaron kennell

Views

10269

Rezo 1390 100W CO2 Laser

This laser is a beast. Designed by Jonathan Frost, and built with 45x45mm aluminum for ultimate rigidity. It has a 4'x3' bed with a pass through that can be utilized to cut full 8x4' sheets of plywood, and has a motorized bed. Rēzo is not only faster and more capable than lasers like Thunder Lasers Nova 51 and Aeon Nova 10, but the final build costs are 40-60% less than said commercially available machines. Plans can be found at https://rezo1390.bigcartel.com/product/rezo-1390-plans

Build Author

cnc-trucker

Views

3899

Build Author

cnc-trucker

Views

3899

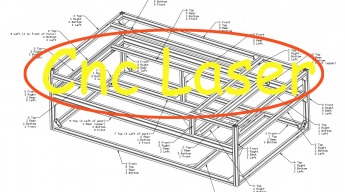

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

Build Author

The Dude

Views

21725

Build Author

The Dude

Views

21725

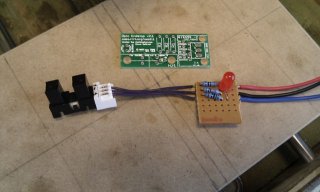

Optical Limit + Home Switches

Optical home and limit switches for cnc, 3D printers, laser cutters, etc.

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

The Buffalo

OX 1500 x 1000 mm

Build Author

Mohsen Abbasi

Views

8282

Build Author

Mohsen Abbasi

Views

8282

Portable Foam Cutter

A portable foam cutter to make your forms everyware using a LiPo Battery.

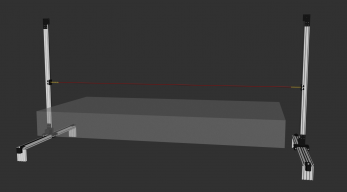

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

Time Lapse Camera Slider

This is my first go at building a simple Time lapse camera rail system using as much pre-existing hardware and software as I could.

Guitar shop CNC

Great bit of kit time will tell if it is up to the job

Build Author

rusirius

Views

16781

Build Author

rusirius

Views

16781

MultiBOT LRP

A CNC platform designed with swapable heads to do laser engraving/etching/cutting, routing and milling, as well as 3D printing.

Build Author

Mark Carew

Views

19353

Build Author

Mark Carew

Views

19353

V-Slot Modular Sit/Stand Desk

In this build we put together an awesome modular stand-up or sit down desk that is perfect of any home or office.

Build Author

M^3

Views

17546

Build Author

M^3

Views

17546

M Cubed 3 Axis Bluetooth CNC Controller

Low cost, Bluetooth enabled, 3 axis CNC controller. GRBL 0.9 compatible.

Build Author

Kermareg

Views

17269

Build Author

Kermareg

Views

17269

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

Steve hope

Views

19121

Build Author

Steve hope

Views

19121

8x4 CNC build

Routy cnc upgrade.

Build Author

brw_racing

Views

16098

Build Author

brw_racing

Views

16098

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

motopreserve

Views

9022

Build Author

motopreserve

Views

9022

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Laurence Carroll

Views

10902

Build Author

Laurence Carroll

Views

10902

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Build Author

Jesse Jenkins

Views

9368

Build Author

Jesse Jenkins

Views

9368

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Sam Dobbie

Views

7734

Build Author

Sam Dobbie

Views

7734

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

Build Author

Neptunes Guitars

Views

8442

Build Author

Neptunes Guitars

Views

8442

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

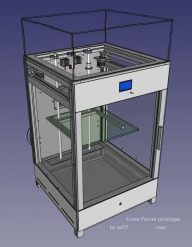

Tower Printer

Tower Printer H-Belt type printer Prototype

Build Author

UltiBots

Views

13592

Build Author

UltiBots

Views

13592

Metal MagBall Carriage

UltiBots LLC designs and packages DeltaBot 3D printers using quality components. Our kits are V-Slot based. Print results are impressive. The Metal MagBall Carriage was designed to be ridged, compact, and simple.

MakerSL MSL-6 DLP 3D Printer

This will be a DLP 3D Printer designed around an Openbuilds Frame and rail system. It will be a collaborated effort between myself and Ben Smith. We will be building two prototypes.

Build Author

cbordeleau

Views

13112

Build Author

cbordeleau

Views

13112

OpenBuilds C-Beam Double Slider

This slider uses an 500mm OpenBuilds C-beam and the design is such that the effective length of the slider is slightly less then twice the length of the C-Beam. It can be used both motorized or not.

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

C-Beam based modular Resin Printer

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

MOJO 3D

Fast, Large build area, CoreXY design