Build List

-

Active Filters:

or

Build Author

Indieflow

Views

115762

Build Author

Indieflow

Views

115762

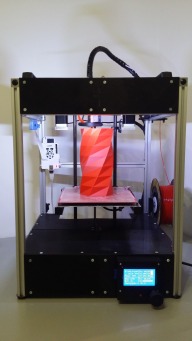

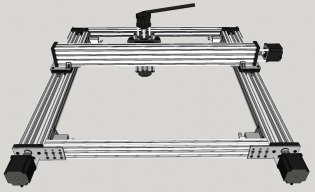

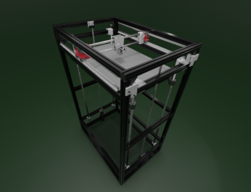

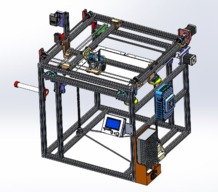

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Build Author

crypt-tek

Views

34507

Build Author

crypt-tek

Views

34507

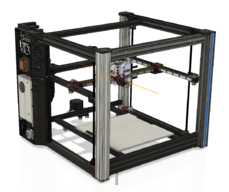

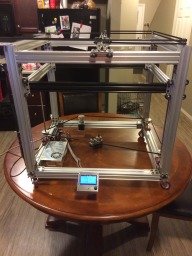

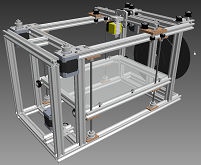

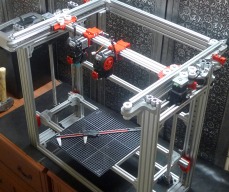

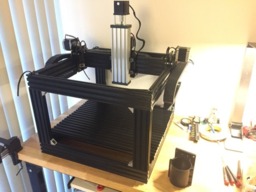

C3DO

My first 3D printer build. It is almost complete and will be posting the first completed print shortly. I still need to mount the print spools and a couple other odd ends to complete this.

Build Author

Carl Feniak

Views

284941

Build Author

Carl Feniak

Views

284941

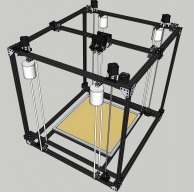

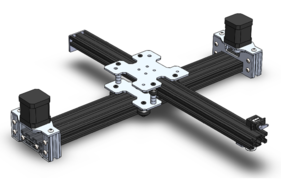

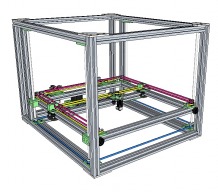

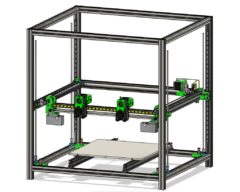

C-Bot

A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy.

Build Author

T4Concepts

Views

81289

Build Author

T4Concepts

Views

81289

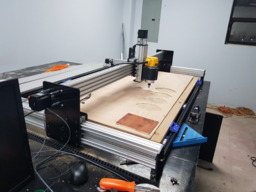

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

Neil Rosenberg

Views

41911

Build Author

Neil Rosenberg

Views

41911

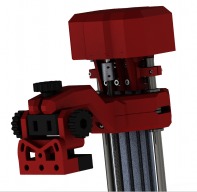

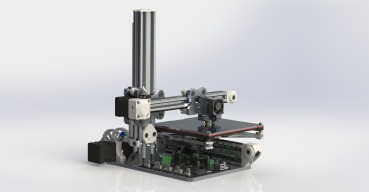

Dash-X 3D Printer: Innovative design

Cross-beam Cartesian 3d printer with dual master/slave lightweight fiberglass drive shafts, BMG style extruder with Bowden (Capricorn) tubing. Hot end is Creality Ender 3 style with two fans and BLTouch for autoleveling. Filament runout sensor is also included.

Build Author

Retsaj

Views

74001

Build Author

Retsaj

Views

74001

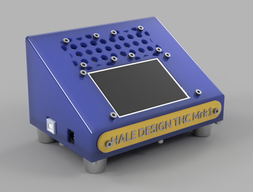

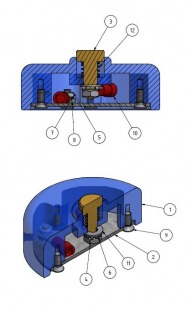

Standalone Torch Height Controller for CNC Plasma Cutting

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

Build Author

SOA

Views

63807

Build Author

SOA

Views

63807

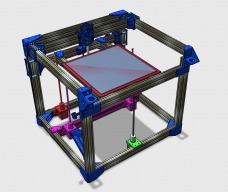

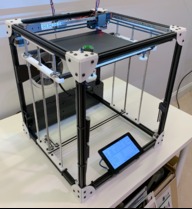

GridBot Two: Powerfully Simple

Core XY, sensor-less homing, integrated camera, touch screen, pi, 32-bit controller, fast, quiet, beautiful prints. 300 x 300 x any build volume. Just change out the Z lead screws, rods, and four pillars. Total BOM around $700 USD. Build time around 6 hours.

Build Author

Joe Young

Views

14879

Build Author

Joe Young

Views

14879

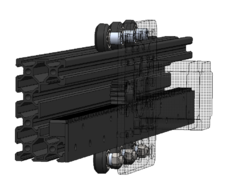

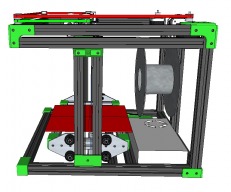

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Leonard Cross

Views

38327

Build Author

Leonard Cross

Views

38327

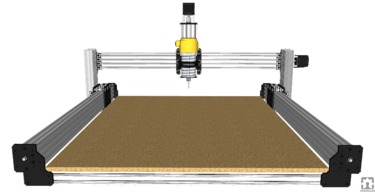

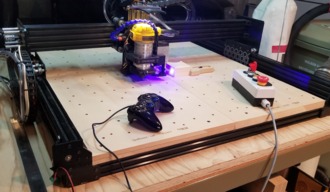

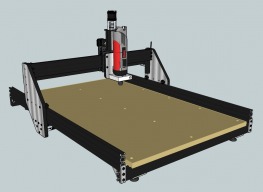

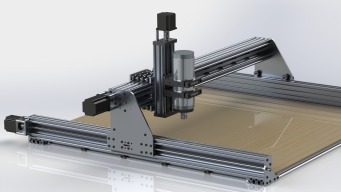

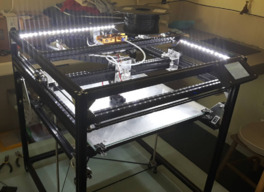

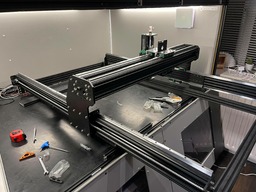

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

Build Author

Jacob Lotter

Views

27321

Build Author

Jacob Lotter

Views

27321

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

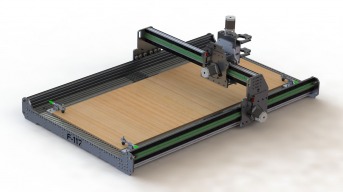

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Build Author

shanehooper

Views

28349

Build Author

shanehooper

Views

28349

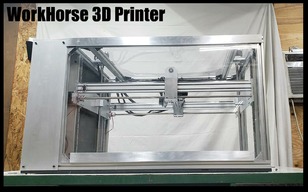

Workhorse 3D Printer

Large 600mm x 350mm x 350mm Build Volume with lead screw driven motion. The printer build has a moving gantry and fixed heat bed. Open Source

Build Author

Gary Caruso

Views

24933

Build Author

Gary Caruso

Views

24933

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Some Improvements on the Workbee 1000x1000

Improvements both real and suggested for the Workbee assembly

Build Author

alex_b

Views

19050

Build Author

alex_b

Views

19050

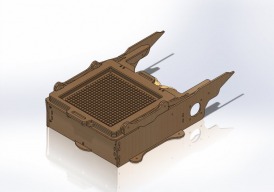

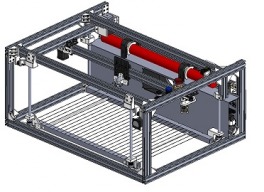

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Build Author

Ryan Lock

Views

145394

Build Author

Ryan Lock

Views

145394

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Build Author

alan richard

Views

51347

Build Author

alan richard

Views

51347

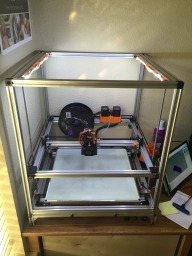

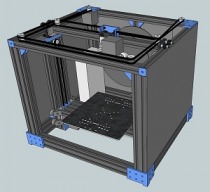

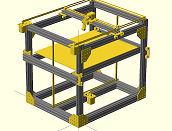

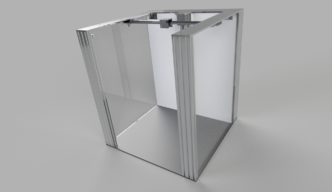

Core-XY Cube

An enclosed cube shaped 3D printer using CoreXY motion. Fabricated from V slot extrusion, standard extrusion, aluminium plate and acrylic sheet using basic workshop tools. Using standard RAMPS/ Reprap electronics. Technically a 'Repstrap' currently used to build a true 'Reprap'

Build Author

Naomi Wu

Views

10844

Build Author

Naomi Wu

Views

10844

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Build Author

Keith Davis

Views

31513

Build Author

Keith Davis

Views

31513

OpenXY

Combines the layout factor of a CoreXY while using Cartesian logic. The design has a fixed build plate - moving an X/Y frame on the Z axis enclosed by an outer main frame.

Build Author

rengelking

Views

39773

Build Author

rengelking

Views

39773

Vacuum Forming Machine

Vacuum Former built with off-the-shelf parts, works perfectly every time!

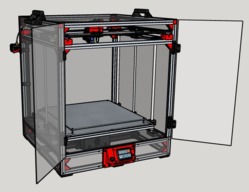

CoreXY W/ Fixed Build Plate & Enclosure

Building a Core XY printer with a fixed build plate from off the shelf parts.

Build Author

Lumberjack Engineering

Views

20213

Build Author

Lumberjack Engineering

Views

20213

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Build Author

Serge E.

Views

61088

Build Author

Serge E.

Views

61088

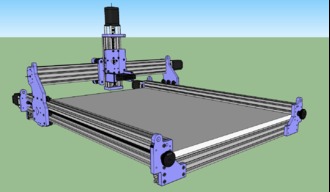

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

TITANXY (Fixed Build Plate, Quad Z Screw, CoreXY)

Super Rigid CoreXY 3D Printer

Build Author

j0achim

Views

12362

Build Author

j0achim

Views

12362

CoreXY - e3d inspired

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Build Author

Rat Rig

Views

31667

Build Author

Rat Rig

Views

31667

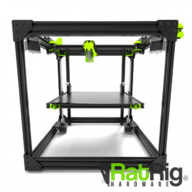

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

Adjustable Router Guide Template

This project is an adjustable router guide template made with 20x60 V-slot. It was meant as a less expensive and more user friendly alternative to commercially available units.

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Build Author

Mike Campbell

Views

11153

Build Author

Mike Campbell

Views

11153

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

BeTrue3D

Views

22425

Build Author

BeTrue3D

Views

22425

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

winand

Views

18030

Build Author

winand

Views

18030

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

Build Author

OffAxis

Views

7759

Build Author

OffAxis

Views

7759

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

cdsmith12

Views

47730

Build Author

cdsmith12

Views

47730

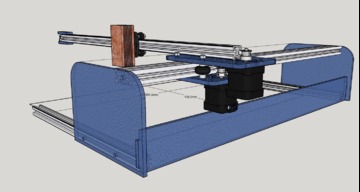

The Plastic Beast CoreXY Printer

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Build Author

Roy Berntsen

Views

27220

Build Author

Roy Berntsen

Views

27220

V-King CoreXY

V-King CoreXY 3d Printer- 380*340*340 Build volume - All wheels on V-Slots - Belts on XYZ - High quality and controlled design - Proven fast, reliable and it is all open source

Build Author

Troy Joachim

Views

19464

Build Author

Troy Joachim

Views

19464

Sigron IDEX

BNC3D Signax + Voron = Sigron IDEX

Build Author

Scott Drake

Views

26625

Build Author

Scott Drake

Views

26625

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

CoreXY Enclosed

A compact, enclosed Core XY design, based on off-the-shelf parts.

Build Author

adamcooks

Views

43382

Build Author

adamcooks

Views

43382

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Build Author

Eric Jacobsson

Views

15452

Build Author

Eric Jacobsson

Views

15452

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

V-Baby CoreXY - Quality Engineered DIY 3d Printer

Easy to build - affordable opensource DIY CoreXY 3d Printer for fast reliable prototyping on your desktop - All wheels and V-Slots for smooth quick moves and opensource firmware on 8 or 32 bit controllers

Build Author

Frank Del Favero

Views

9757

Build Author

Frank Del Favero

Views

9757

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

G&C Printer

The name of the printer is G&C Printer from Good & Cheap Printer. My goal was to design an printer that was good print quality and was cheap. The total cost of the printer is about 490€.

Build Author

Peter Oakes

Views

44330

Build Author

Peter Oakes

Views

44330

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Build Author

Mark Carew

Views

77874

Build Author

Mark Carew

Views

77874

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Phlatformer v2

Hello, I have been looking around for a vacuum forming machine for a long time, and could not find one that was either in my price range or was safe enough for me to want in my home. The Phlatformer answers both of these requirements... Unfortunately, it was not available in either cut-out or...

Build Author

AK-Creation

Views

14974

Build Author

AK-Creation

Views

14974

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

jz321

Views

4582

Build Author

jz321

Views

4582

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Mark Carew

Views

85312

Build Author

Mark Carew

Views

85312

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

Build Author

Ronald van Arkel

Views

16647

Build Author

Ronald van Arkel

Views

16647

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Dragon Portable CNC Plasma Cutter

A small portable CNC Plasma Cutter with some unique features

Build Author

nc3dpw

Views

24368

Build Author

nc3dpw

Views

24368

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

rkugler

Views

6899

Build Author

rkugler

Views

6899

Miter Saw Stop Block

Just starting a miter saw stop system. Any suggestions appreciated.

Build Author

John Bolduc

Views

5979

Build Author

John Bolduc

Views

5979

SG Duet Delta

This my version of a large no corners cut Delta.

Build Author

Mark Rehorst

Views

10200

Build Author

Mark Rehorst

Views

10200

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Workbee with Duet controller

Workbee 1010 with Duet controller from Ooznest

Build Author

James Evanko

Views

7325

Build Author

James Evanko

Views

7325

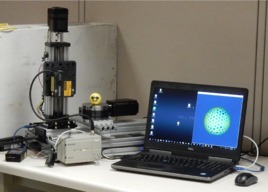

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

OKMI 3d Printer

OKMI 3d Printer based on CoreXY

Build Author

Steve B

Views

15722

Build Author

Steve B

Views

15722

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Build Author

Rob Taylor

Views

20326

Build Author

Rob Taylor

Views

20326

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

Bridge Port

Views

9273

Build Author

Bridge Port

Views

9273

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Build Author

Apothus

Views

22522

Build Author

Apothus

Views

22522

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

CharlieShimota

Views

16246

Build Author

CharlieShimota

Views

16246

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

crypt-tek

Views

10066

Build Author

crypt-tek

Views

10066

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

KeePrint Monster

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.

Suitcase Vacuumformer

Quick overview of my build up for a vacuum former that is self contained, portable and fairly easy to build.

Build Author

Sheepdog

Views

26862

Build Author

Sheepdog

Views

26862

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Build Author

Mark Carew

Views

109103

Build Author

Mark Carew

Views

109103

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

Hytech2k

Views

33963

Build Author

Hytech2k

Views

33963

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

KALΔIS OPEN SLA

Modular easy to adjust scale of the entire build Tablet/LCD monitor SLA 3d Printer.

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

Joe Young

Views

5934

Build Author

Joe Young

Views

5934

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

CoreCube3D

Views

22097

Build Author

CoreCube3D

Views

22097

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Build Author

Jason Moore

Views

13125

Build Author

Jason Moore

Views

13125

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Build Author

Mark Carew

Views

93171

Build Author

Mark Carew

Views

93171

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

Build Author

Mark Carew

Views

64926

Build Author

Mark Carew

Views

64926

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

Keith Davis

Views

20729

Build Author

Keith Davis

Views

20729

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

SCoreXY

Currently I have Velleman/3Drag K8200 modified and CNC machine self built and wanted to use both to make new 3D printer. After looking at different designs I liked Voron a lot and have decided to go that way. Currently I have ordered majority of parts and build shall start soon. I don't plan to rush it as I am usually 2 months home and 2 off. Today done some electronics. Looks ok. https://youtu.be/ls_tl54ruE0

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

The Almost Perfect 3 Way Mitre (with MakerLinks)

A quick and easy way to make a 3-way mitered corner using MakerLinks

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

Draw bot core xy

In the design stage. Help guide.

Build Author

BNMaker

Views

12023

Build Author

BNMaker

Views

12023

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

Build Author

CNCGear

Views

10680

Build Author

CNCGear

Views

10680

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Build Author

Mark Carew

Views

51166

Build Author

Mark Carew

Views

51166

V-Slot SphereBot

This SphereBot is based on the EggBot which is an open-source art robot (drawbot) that can draw on spherical or egg-shaped objects.

Build Author

John J Talavera

Views

18722

Build Author

John J Talavera

Views

18722

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Build Author

Mark Carew

Views

127261

Build Author

Mark Carew

Views

127261

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds