Build List

-

Active Filters:

tr

Build Author

Mark Carew

Views

1214668

Build Author

Mark Carew

Views

1214668

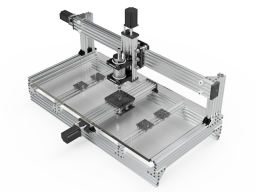

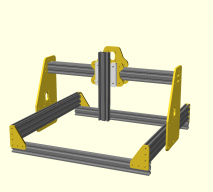

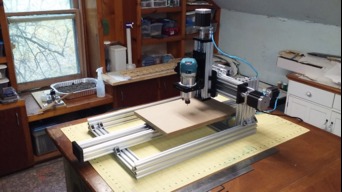

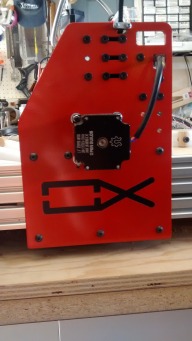

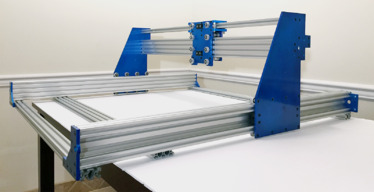

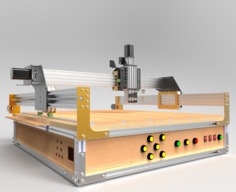

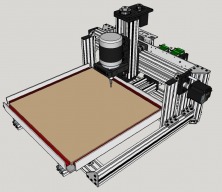

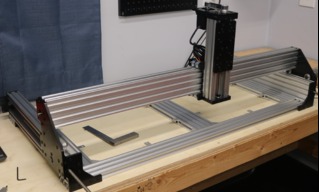

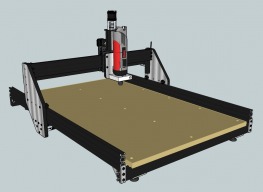

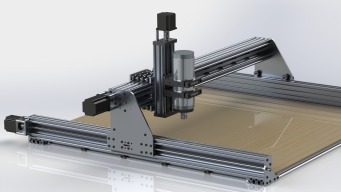

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

Indieflow

Views

116234

Build Author

Indieflow

Views

116234

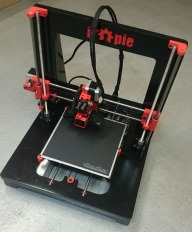

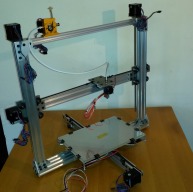

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Build Author

Michael.M

Views

69658

Build Author

Michael.M

Views

69658

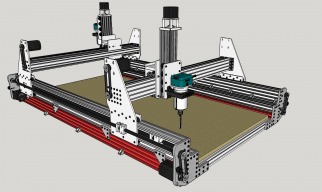

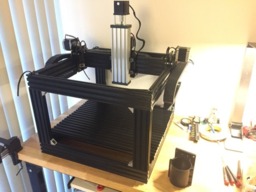

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

Build Author

sausagePaws

Views

80476

Build Author

sausagePaws

Views

80476

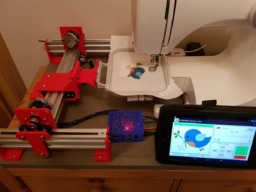

Embroidery machine with XY belt and pinion drive.

A simple Embroidery machine using an XY belt and pinion drive to drive a hoop under a standard sewing machine. Needle timing, machine power and stepper control are all provided by a PIC processor. A tablet provides the higher level formatting required for communicating with the PIC chip.

Build Author

crypt-tek

Views

34686

Build Author

crypt-tek

Views

34686

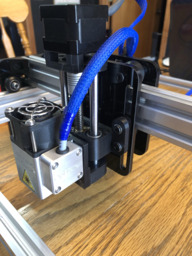

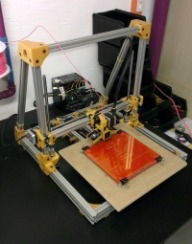

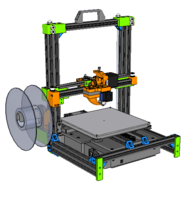

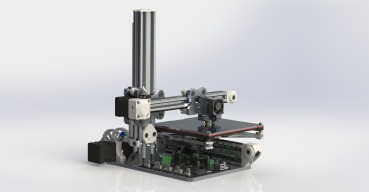

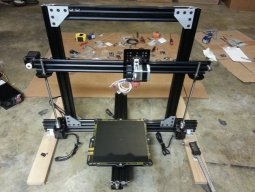

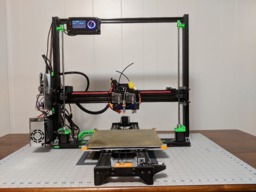

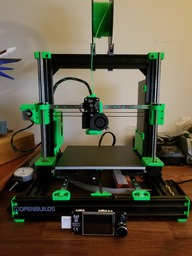

C3DO

My first 3D printer build. It is almost complete and will be posting the first completed print shortly. I still need to mount the print spools and a couple other odd ends to complete this.

Build Author

T4Concepts

Views

82275

Build Author

T4Concepts

Views

82275

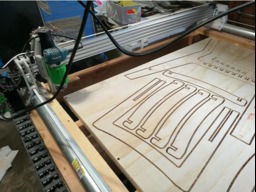

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

MarkM_NJ

Views

20178

Build Author

MarkM_NJ

Views

20178

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

Build Author

sausagePaws

Views

1761544

Build Author

sausagePaws

Views

1761544

DIY Embroidery Machine V2

My second attempt at an affordable sewing machine embroidery add on. This one uses readily available electronics modules and 3D printable parts where possible.

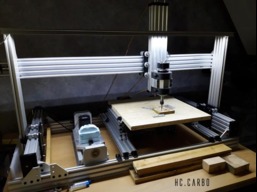

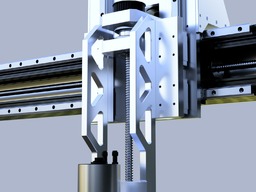

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Build Author

pek

Views

85240

Build Author

pek

Views

85240

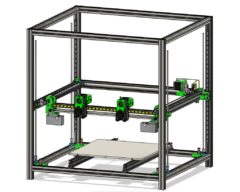

Prusa i3 Bear Upgrade V2

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Build Author

Retsaj

Views

76153

Build Author

Retsaj

Views

76153

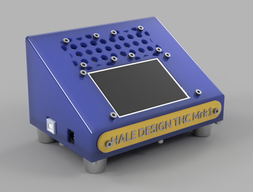

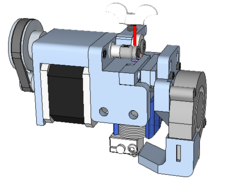

Standalone Torch Height Controller for CNC Plasma Cutting

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

Build Author

Mark Carew

Views

221499

Build Author

Mark Carew

Views

221499

LEAD CNC 1010 (40" x 40")

The OpenBuilds Lead Machine takes us back to the roots of the OpenBuilds modular building system, and has proven itself as an adaptable design that can compete with any machine in its class!

Build Author

Janis93

Views

16036

Build Author

Janis93

Views

16036

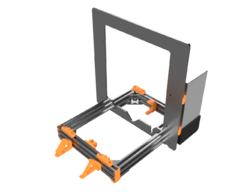

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Build Author

Rob Taylor

Views

19349

Build Author

Rob Taylor

Views

19349

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Build Author

stephen cia

Views

36718

Build Author

stephen cia

Views

36718

ZideX

3D printer with 7 drivers, compact, dual extruder, no CNC part. All Openbuilds and 3D printed part. This is purely experimental.

Build Author

blterry1

Views

19472

Build Author

blterry1

Views

19472

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Build Author

roadss

Views

26315

Build Author

roadss

Views

26315

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

HPB

Views

48477

Build Author

HPB

Views

48477

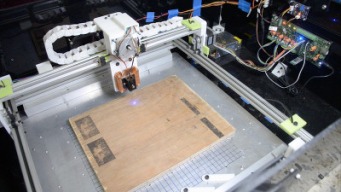

A simple XY laser engraver/cutter

A simple low-cost XY plane laser engraver/cutter inspired by the Much 4 laser build, with minimal parts and assembly time. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3D printed.

Build Author

alex_b

Views

19420

Build Author

alex_b

Views

19420

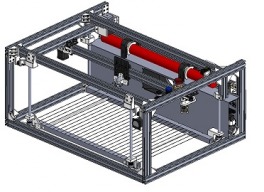

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Z-Axis for Laser Diode

Custom Z Axis for OptLaser 6watt and the Acro System

Build Author

Cuong Vu

Views

35980

Build Author

Cuong Vu

Views

35980

3D Printer

It took me 18 long nights to build it

Build Author

alan richard

Views

52011

Build Author

alan richard

Views

52011

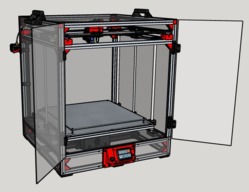

Core-XY Cube

An enclosed cube shaped 3D printer using CoreXY motion. Fabricated from V slot extrusion, standard extrusion, aluminium plate and acrylic sheet using basic workshop tools. Using standard RAMPS/ Reprap electronics. Technically a 'Repstrap' currently used to build a true 'Reprap'

Build Author

Naomi Wu

Views

11059

Build Author

Naomi Wu

Views

11059

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

Build Author

Lumberjack Engineering

Views

20403

Build Author

Lumberjack Engineering

Views

20403

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

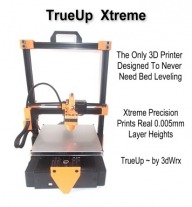

TrueUp Glide

A Cartesian printer using bushings for the Z axis instead of wheels or linear bearings. The design also synchronizes two Z axis screws with a timing belt for a level lift. The ratio of the drive pulley and Z axis pulleys produce .005 lift per full step on a 200 step motor, eliminating layer resolution "drift" caused by microstepping.

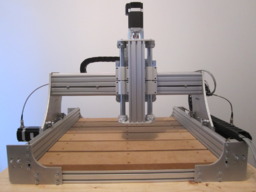

Ooznest Ox with 3D Printed Gantry Plates

Ooznest Ox with gantry plates and end caps 3D printed in ABS rather than aluminum.

TrueUp Kit Version

A Cartesian printer using bushings for the Z axis instead of wheels or linear bearings. The design also synchronizes two Z axis screws with a timing belt for a level lift. The ratio of the drive pulley and Z axis pulleys produce .005 lift per full step on a 200 step motor, eliminating layer resolution "drift" caused by microstepping.

Build Author

Michael.M

Views

9861

Build Author

Michael.M

Views

9861

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

Metalguru

Views

14999

Build Author

Metalguru

Views

14999

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Gerald Klein

Views

17689

Build Author

Gerald Klein

Views

17689

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

Build Author

Gooshpoo

Views

9605

Build Author

Gooshpoo

Views

9605

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

Kyo

Views

46663

Build Author

Kyo

Views

46663

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Software speed control of a brushless dc (Bldc) motor from Mach3.

Although this build is typically Mach3 related there is no reason it cannot be adapted for use with any machine control software which provides a PWM spindle control output. As an addition, an option has now been added which will enable the interface to manually control outrunner speed without the need for a PWM signal.

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Build Author

Spark Concepts

Views

17129

Build Author

Spark Concepts

Views

17129

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

Mini-OX

An OX-inspired mini desktop mill. Designed in OpenSCAD, these parts are fully parametric and can be customized to your liking.

Build Author

Sword66

Views

14252

Build Author

Sword66

Views

14252

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

Build Author

winand

Views

18224

Build Author

winand

Views

18224

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

OffAxis

Views

7963

Build Author

OffAxis

Views

7963

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

cdsmith12

Views

51840

Build Author

cdsmith12

Views

51840

The Plastic Beast CoreXY Printer

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Build Author

Troy Joachim

Views

19960

Build Author

Troy Joachim

Views

19960

Sigron IDEX

BNC3D Signax + Voron = Sigron IDEX

Build Author

mytechno3d

Views

16502

Build Author

mytechno3d

Views

16502

Cut To Length Machine

A Cut To Length machine controlled by computer

Build Author

adamcooks

Views

43571

Build Author

adamcooks

Views

43571

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Build Author

Eric Jacobsson

Views

15740

Build Author

Eric Jacobsson

Views

15740

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

Lautr3k RepRap

A 3D printer without belts, a print volume of 320x320x260mm, obviously the V-Slot as linear guide! and a maximum of printed pieces.

Build Author

Peter Oakes

Views

44624

Build Author

Peter Oakes

Views

44624

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Build Author

Mark Carew

Views

91789

Build Author

Mark Carew

Views

91789

BlackBox Motion Control System

The Openbuilds BlackBox is a new system evolved around a set of subsystems that cover more than just control and also more than just CNC type applications! With a plug-and-play easy connection system this controller can be used with ease, without sacrificing power.

Build Author

UltiBots

Views

33288

Build Author

UltiBots

Views

33288

Mini Kossel V-Slot 3D Printer

This build is very straight forward. The design is simple. There is a great support community for Delta 3D printers.

iTopie RepRap - 3D Printer

A stable and strong 3D printer made of 16mm MDF and machined on my OX.

Build Author

pek

Views

27354

Build Author

pek

Views

27354

Prusa i3 Bear Half Upgrade v1.0

Stronger frame for Prusa i3 MK2 / MK2s / MK2.5 3D printer

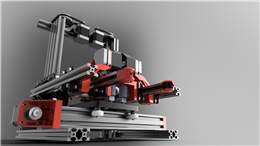

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

jtaggard

Views

37904

Build Author

jtaggard

Views

37904

Modular DIY CNC Machine

This modular CNC machine is based on the OpenBuilds ACRO System, however I wanted something that did more than just laser engrave. So I designed my machine using the same style as the ACRO but with some upgrades such as an actual Z-axis and the ability for multiple tool attachments.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

jz321

Views

4715

Build Author

jz321

Views

4715

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Scott Martinez

Views

12428

Build Author

Scott Martinez

Views

12428

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

OpenBuilds LEAD CNC Machine 1515 (60" x 60")

It began with creating an extremely rigid axis that incorporates a multi C-Beam Linear Rail system as well as precision lead screws coupled with a tension system for the absolute maximum in performance.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

Build Author

Ronald van Arkel

Views

16826

Build Author

Ronald van Arkel

Views

16826

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

nc3dpw

Views

24759

Build Author

nc3dpw

Views

24759

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

rkugler

Views

7074

Build Author

rkugler

Views

7074

Miter Saw Stop Block

Just starting a miter saw stop system. Any suggestions appreciated.

Build Author

BinaryConstruct

Views

10389

Build Author

BinaryConstruct

Views

10389

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

James Evanko

Views

7602

Build Author

James Evanko

Views

7602

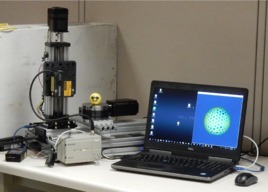

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Build Author

ajdubs

Views

5879

Build Author

ajdubs

Views

5879

A custom arcade

This is an arcade "cabinet" of sorts built almost entirely from OpenBuilds extrusions. Save for a few 3d printed parts, the electrical components, the acrylic panels, and the monitor mount, every component was purchased from the OpenBuilds part store.

Build Author

Mark Carew

Views

110111

Build Author

Mark Carew

Views

110111

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

SlyClockWerkz

Views

17068

Build Author

SlyClockWerkz

Views

17068

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Build Author

Apothus

Views

22674

Build Author

Apothus

Views

22674

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

TrueUp Bold

A beefed up modification of the TrueUp Kit project

C_Beam Hammerhead 5x

setup for learning 5x

Build Author

Spark Concepts

Views

5562

Build Author

Spark Concepts

Views

5562

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

Build Author

Sergio Di Ventura

Views

9511

Build Author

Sergio Di Ventura

Views

9511

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

Sheepdog

Views

27027

Build Author

Sheepdog

Views

27027

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Build Author

Hytech2k

Views

34160

Build Author

Hytech2k

Views

34160

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

Build Author

James Archer

Views

14710

Build Author

James Archer

Views

14710

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Build Author

Rob Mahan

Views

14236

Build Author

Rob Mahan

Views

14236

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Glenn Weston

Views

11715

Build Author

Glenn Weston

Views

11715

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Build Author

Tommy Williamson

Views

7333

Build Author

Tommy Williamson

Views

7333

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Joe Young

Views

6102

Build Author

Joe Young

Views

6102

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

Jason Moore

Views

13438

Build Author

Jason Moore

Views

13438

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Build Author

GDanger117

Views

12649

Build Author

GDanger117

Views

12649

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Keith Davis

Views

5569

Build Author

Keith Davis

Views

5569

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

GinoTheCop

Views

14775

Build Author

GinoTheCop

Views

14775

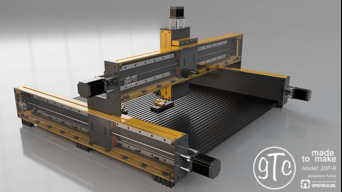

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

OpenBuilds

Views

30471

Build Author

OpenBuilds

Views

30471

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

Mark Carew

Views

134333

Build Author

Mark Carew

Views

134333

V-Slot® NEMA 17 Linear Actuator (Belt Driven)

Quick and Simple V-Slot Gantry System. This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts. You can mount this system an many ways so be sure to download the example models.

Build Author

crystaldragon141

Views

6728

Build Author

crystaldragon141

Views

6728

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

megashub

Views

24665

Build Author

megashub

Views

24665

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Automatic Sprayer

Automatic spray machine.

Build Author

Carl Siren

Views

7801

Build Author

Carl Siren

Views

7801

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Calotype

Views

3685

Build Author

Calotype

Views

3685

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !