Build List

-

Active Filters:

be

Build Author

Carl Siren

Views

7596

Build Author

Carl Siren

Views

7596

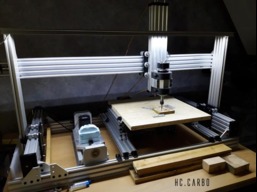

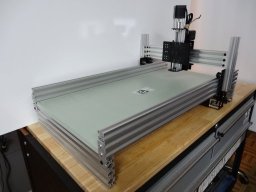

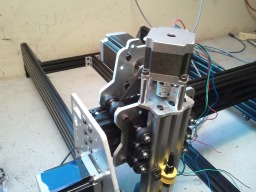

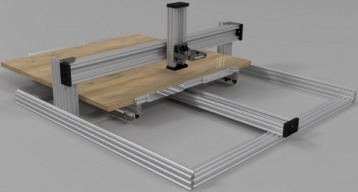

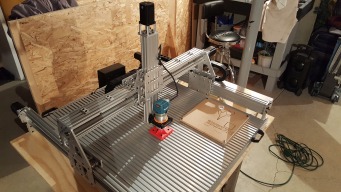

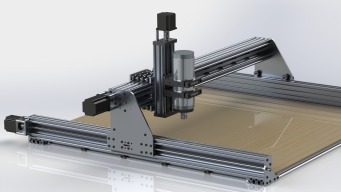

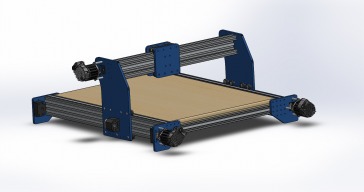

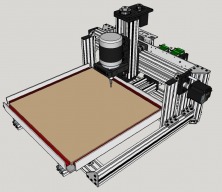

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

C_Beam Hammerhead 5x

setup for learning 5x

Build Author

hbtousa

Views

3229

Build Author

hbtousa

Views

3229

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

HuguesP

Views

9198

Build Author

HuguesP

Views

9198

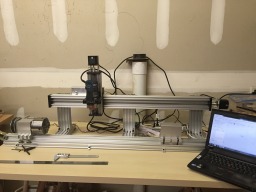

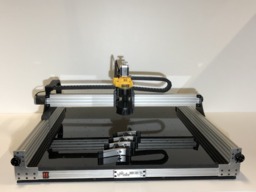

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Build Author

Mark Carew

Views

84716

Build Author

Mark Carew

Views

84716

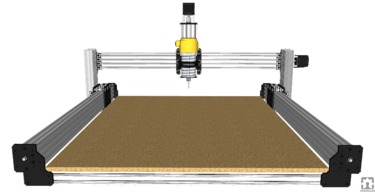

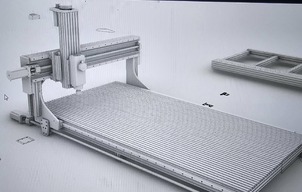

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Build Author

Mark Carew

Views

54465

Build Author

Mark Carew

Views

54465

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Build Author

Mark Carew

Views

13620

Build Author

Mark Carew

Views

13620

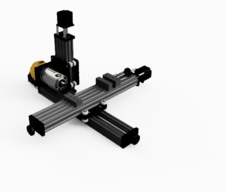

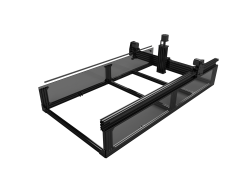

C-Beam® Double Wide Gantry Actuator

This easy to build actuator is configured to have not only strength, but accuracy! This low profile option offers endless possibilities, and we cant wait to see how this actuator is implemented in your build ideas!

Build Author

James Evanko

Views

4050

Build Author

James Evanko

Views

4050

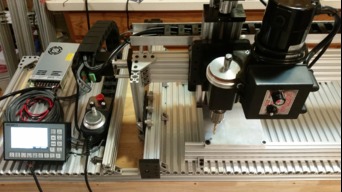

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Build Author

crypt-tek

Views

9986

Build Author

crypt-tek

Views

9986

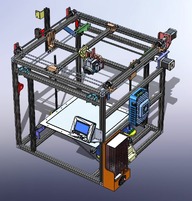

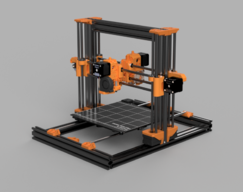

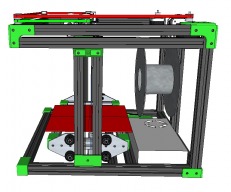

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Build Author

Ariel Yahni

Views

6525

Build Author

Ariel Yahni

Views

6525

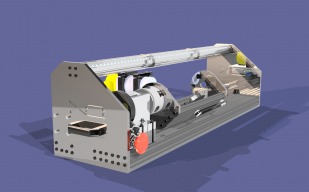

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Build Author

Vunnie

Views

6756

Build Author

Vunnie

Views

6756

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Build Author

SOA

Views

63582

Build Author

SOA

Views

63582

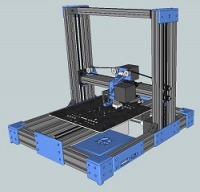

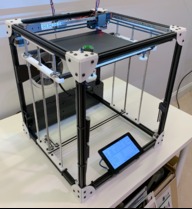

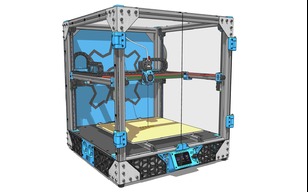

GridBot Two: Powerfully Simple

Core XY, sensor-less homing, integrated camera, touch screen, pi, 32-bit controller, fast, quiet, beautiful prints. 300 x 300 x any build volume. Just change out the Z lead screws, rods, and four pillars. Total BOM around $700 USD. Build time around 6 hours.

C-Beam Dust Shoe

A short description of the dust shoe I made for my machine.

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

Build Author

Kenneth Witthuhn

Views

8449

Build Author

Kenneth Witthuhn

Views

8449

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Build Author

OpenBuilds

Views

6657

Build Author

OpenBuilds

Views

6657

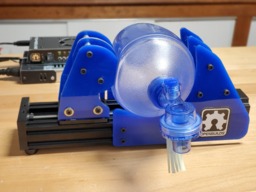

V-Slot Ventilator

The idea is to make a simple effective ventilator, studying the concept of using a simple push process with and actuator.

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Build Author

Stokrotka74

Views

6861

Build Author

Stokrotka74

Views

6861

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Build Author

Corey Corbin

Views

7406

Build Author

Corey Corbin

Views

7406

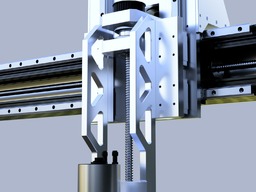

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

Kyo

Views

28428

Build Author

Kyo

Views

28428

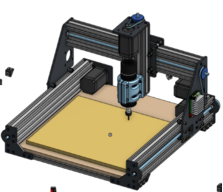

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Build Author

nickchnv

Views

12479

Build Author

nickchnv

Views

12479

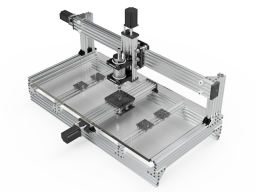

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

Build Author

Edgar Mata

Views

31113

Build Author

Edgar Mata

Views

31113

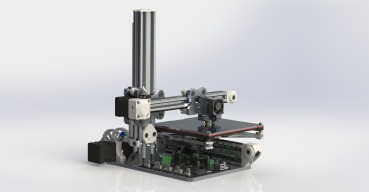

ME - Core XY 3d printer

I wanted to make my own Voron, so I made my own Voron,

Dash X Direct, Cross-Beam 3d Printer

This is the next version of Dash, now operating much closer to its potential. Please message me if you need anything, such as Simplify3D settings, material information, design intent etc. Since the Pack-and-Go zip file is fairly large (120mB), here is a link where it can be downloaded: https://drive.google.com/file/d/1Q3ygyo_tTrB4UYIV62_wtCSCbWuE3krT/view?usp=sharing Note: I use Solidworks 2022, acquired through their Solidworks for Makers program (check it out!). A super deal at $100/yr

Build Author

EvanH

Views

4726

Build Author

EvanH

Views

4726

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

ROUTY CNC Router (V-Slot Belt & Pinion)

A cool little CNC router build that uses the V-Slot belt & pinion drive and stock parts.

Build Author

T4Concepts

Views

80595

Build Author

T4Concepts

Views

80595

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

ymilord

Views

59497

Build Author

ymilord

Views

59497

FARM OX (Four Axis Rotary Machine)

Four Axis Rotary Machine (FARM) OX. Equipped with a X,Z,A & C Axis.

Build Author

Keith Davis

Views

35332

Build Author

Keith Davis

Views

35332

OneZ i3

A quiet, 8inx8in build area, Cartesian printer with permanently level bed. This is a compact, solid, inexpensive printer that will reliably print any type filament for thousands of hours while you sleep, fish, or play ball in the park.

Build Author

Indieflow

Views

115451

Build Author

Indieflow

Views

115451

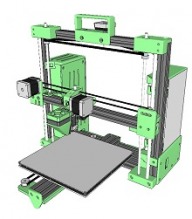

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

All in One Grill -Mangal Schaschlik Döner

I create for some Years this all in one Grill. This Grill is without wellding, only fixed with screws. My Grill is 5 years old and look so, as at the first day (no moving away). The drawings and discription (sorry only in German, but with some pictures) to Download as PDF file. The unwindings to Download as DXF and GEO (Trumpf Laser) file. Have fun to build and Grill

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

Build Author

Leonard Cross

Views

38042

Build Author

Leonard Cross

Views

38042

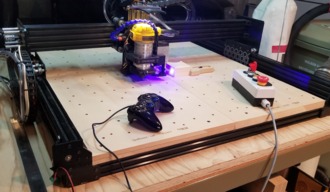

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

Build Author

Kims3DIY

Views

18154

Build Author

Kims3DIY

Views

18154

Beamlazer Laser cutter CO2 100W

Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Then i decided to build my own laser, with some easier workflow and support for Windows 10. Since im still a student i have limited resources, so i will try too use scrap parts as much as possible. I will publish photos and updates during my build continously. Gladly taking advices from others.

Build Author

Mark Carew

Views

126554

Build Author

Mark Carew

Views

126554

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

C Beam Rotary

I've used the good work of Openbuilds & expanded it to suit.

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

Build Author

jamesdjadams

Views

12170

Build Author

jamesdjadams

Views

12170

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Build Author

Apothus

Views

22440

Build Author

Apothus

Views

22440

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

Rob Taylor

Views

18954

Build Author

Rob Taylor

Views

18954

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

Rotary CNC

I'm building a machine specifically for doing 4th axis work on woodwind instruments.

Build Author

M^3

Views

17567

Build Author

M^3

Views

17567

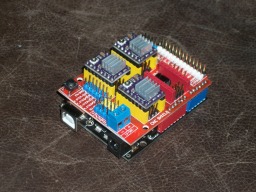

M Cubed 3 Axis Bluetooth CNC Controller

Low cost, Bluetooth enabled, 3 axis CNC controller. GRBL 0.9 compatible.

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

Build Author

Ronald van Arkel

Views

16541

Build Author

Ronald van Arkel

Views

16541

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Build Author

Troy Joachim

Views

18304

Build Author

Troy Joachim

Views

18304

Prusa i3 Bear IDEX

Remix of the Prusa i3 Bear with added IDEX

Build Author

Jason @ MCC

Views

12807

Build Author

Jason @ MCC

Views

12807

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Build Author

Beam

Views

11477

Build Author

Beam

Views

11477

DIY Flywheel Camera Slider

My take on a non affordable slider.

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

Build Author

Josh Mascote

Views

7367

Build Author

Josh Mascote

Views

7367

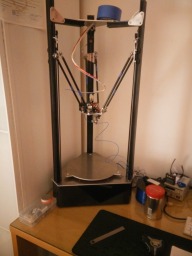

Z3D Delta Printer

Berrybot inspired delta 3d printer with a few other tweaks and modifications.

Build Author

CubeSpawn

Views

16020

Build Author

CubeSpawn

Views

16020

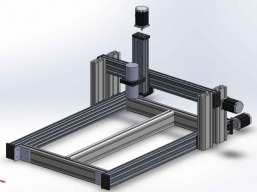

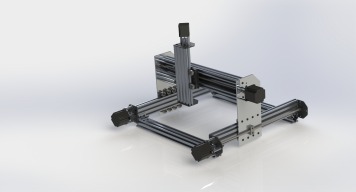

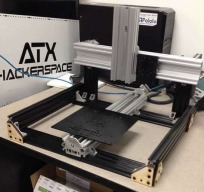

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

BldrBot Pro

A completely belt driven cartesian design with a center mounted X motor. This is a very compact, rugged design.

Build Author

CreativeTools

Views

9387

Build Author

CreativeTools

Views

9387

Universal stand-alone filament spool holder (Fully 3D-printable)

A practical rotating and stand-alone spool holder which fits any filament extrusion 3D-printer. Several base files provided which make it fit different extruded aluminium profiles.

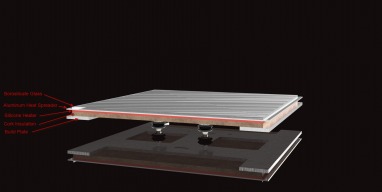

12.5" x 12" Assembled Heated Build Plate

Custom build plate for 300mm x 300mm (12"x12"). The hole pattern is for the 20x60 V Slot

KerryH's OX

My adventure in CNC routing.

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

3D Printer DELTA

Delta printer, Bed size 280 cm dimeter Print Height 300 cm not tested yet the speed

Build Author

inhan

Views

6170

Build Author

inhan

Views

6170

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

motopreserve

Views

9044

Build Author

motopreserve

Views

9044

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

Build Author

Steven Sampson

Views

10884

Build Author

Steven Sampson

Views

10884

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

Keith Davis

Views

20578

Build Author

Keith Davis

Views

20578

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

Build Author

DIY3DTech.com

Views

6469

Build Author

DIY3DTech.com

Views

6469

3D Printer Leveler Made with Maker Rail

Leveling Platform / Stand 3D Printers

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

evildean

Views

8852

Build Author

evildean

Views

8852

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

C beam cnc modified

C beam cnc modified

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

Build Author

Mogens Kusk

Views

5170

Build Author

Mogens Kusk

Views

5170

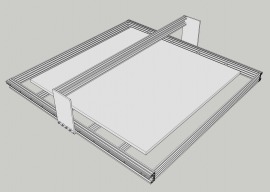

Belt driven 1200mm x 700mm x170mm axis

CNC router

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

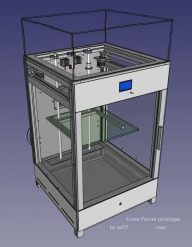

Tower Printer

Tower Printer H-Belt type printer Prototype

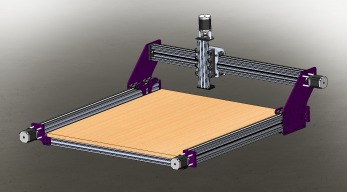

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Build Author

David Arroyo

Views

14554

Build Author

David Arroyo

Views

14554

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Build Author

evil2002usna

Views

11515

Build Author

evil2002usna

Views

11515

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

Builder+Bob

Views

3717

Build Author

Builder+Bob

Views

3717

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Charles Roseberry

Views

5020

Build Author

Charles Roseberry

Views

5020

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Build Author

UltiBots

Views

10515

Build Author

UltiBots

Views

10515

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

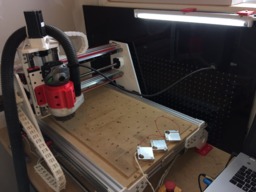

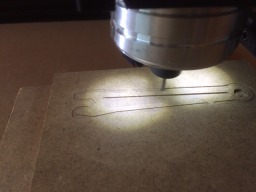

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

Build Author

Metalguru

Views

14565

Build Author

Metalguru

Views

14565

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Rwetzler

Views

9302

Build Author

Rwetzler

Views

9302

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.