Build List

-

Active Filters:

u

Build Author

UltiBots

Views

10515

Build Author

UltiBots

Views

10515

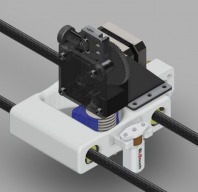

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

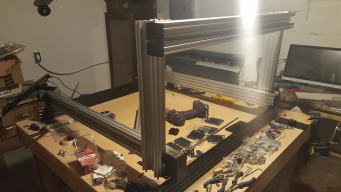

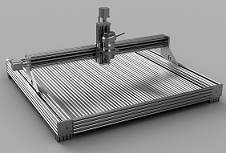

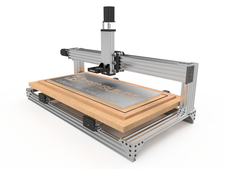

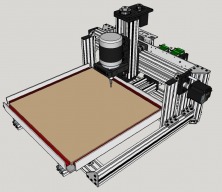

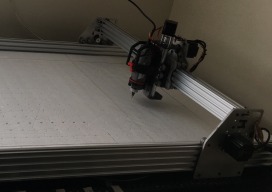

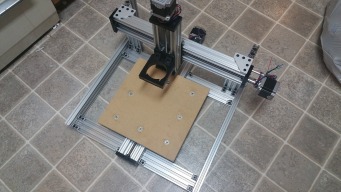

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

Build Author

Metalguru

Views

14566

Build Author

Metalguru

Views

14566

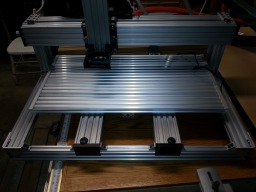

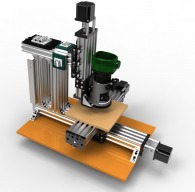

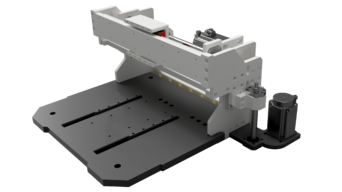

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Rwetzler

Views

9303

Build Author

Rwetzler

Views

9303

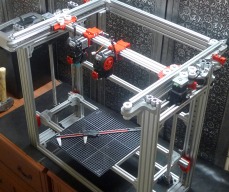

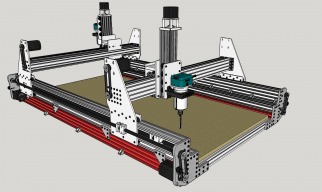

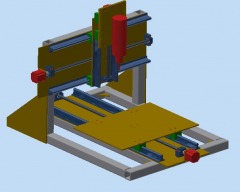

C-Beam Prototype

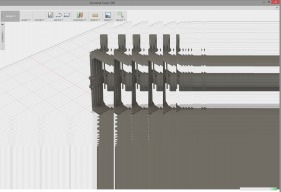

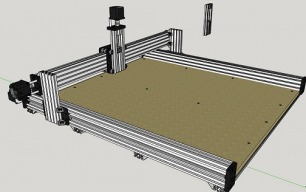

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

griso

Views

9206

Build Author

griso

Views

9206

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Build Author

boubouexpress

Views

11436

Build Author

boubouexpress

Views

11436

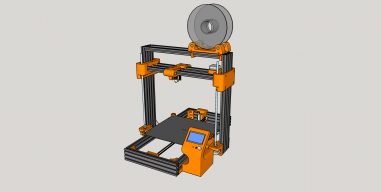

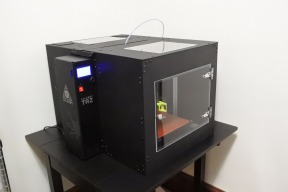

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

Infinite Z Delta Printer

Currently completely imaginary

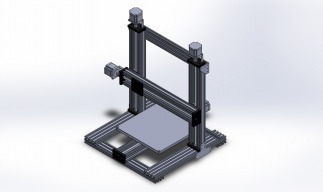

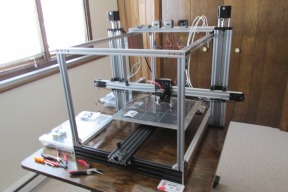

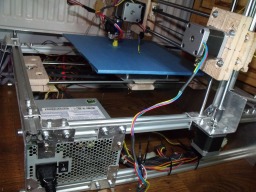

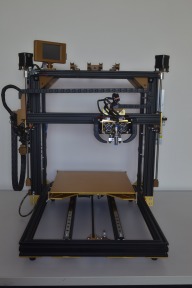

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

Build Author

William Niedermeyer

Views

19524

Build Author

William Niedermeyer

Views

19524

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

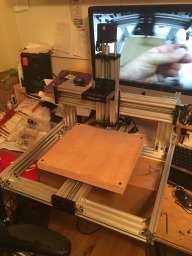

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

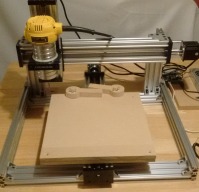

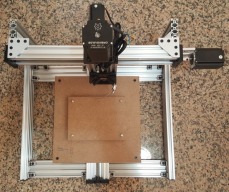

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Build Author

mytechno3d

Views

6446

Build Author

mytechno3d

Views

6446

DSLR ( video ) motorized slider

In order to make some nice traveling video you need a slider .

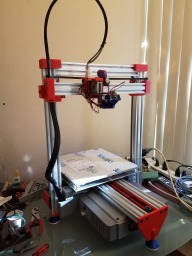

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

BrandoneOuX

I'm Brandoneous; hence, the BrandoneOuX, a cartesian CNC build. Large format (1000mm x 1000mm) but beefed-up to solidly augment the ability to cut Aluminum in addition to wood and other solid materials. As I am currently living in a rented apartment for an out-of-state job, my secondary challenge is to build a sound dampening enclosure that will function as a torsion box base, a sound dampening enclosure, and a dust containment system. Easy, right? Well, we'll see... Join my journey

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

Build Author

Dave420

Views

14449

Build Author

Dave420

Views

14449

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Build Author

Simon Rafferty

Views

7523

Build Author

Simon Rafferty

Views

7523

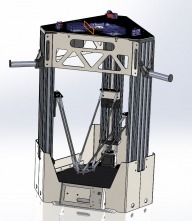

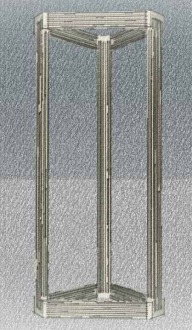

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

Build Author

Krishnakumar

Views

8632

Build Author

Krishnakumar

Views

8632

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

AK-Creation

Views

14849

Build Author

AK-Creation

Views

14849

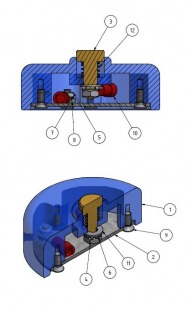

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Build Author

crystaldragon141

Views

6532

Build Author

crystaldragon141

Views

6532

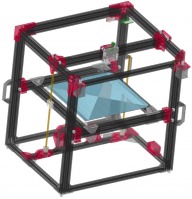

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Build Author

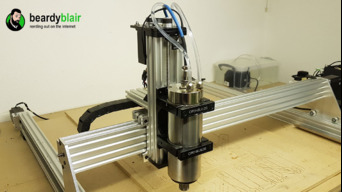

beardyblair

Views

25236

Build Author

beardyblair

Views

25236

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

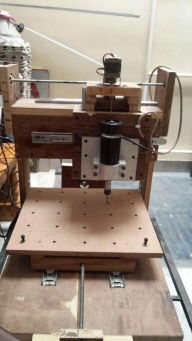

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

Build Author

Edgar Robles

Views

4068

Build Author

Edgar Robles

Views

4068

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

C-Machine

MY experience as a first time introduction to the CNC world!

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Build Author

Ken376

Views

3708

Build Author

Ken376

Views

3708

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Build Author

dodgenet

Views

6536

Build Author

dodgenet

Views

6536

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

mikev

Views

8543

Build Author

mikev

Views

8543

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Anthony Bolgar

Views

5700

Build Author

Anthony Bolgar

Views

5700

Air assist/fume collector for Diode Laser Engraver

This is a work in progress

Build Author

signzonepr

Views

12989

Build Author

signzonepr

Views

12989

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Thair.nl

Views

3759

Build Author

Thair.nl

Views

3759

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Build Author

Linkreincarnate

Views

3103

Build Author

Linkreincarnate

Views

3103

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Build Author

Kyo

Views

6491

Build Author

Kyo

Views

6491

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8491

Build Author

taratata2016

Views

8491

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8513

Build Author

Limine3D

Views

8513

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

COMsulting

Views

10022

Build Author

COMsulting

Views

10022

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

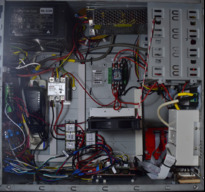

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Clock repair stand

Open source clock movement stand

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Greg Lampman

Views

9168

Build Author

Greg Lampman

Views

9168

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

Tom Dirriwachter

Views

7318

Build Author

Tom Dirriwachter

Views

7318

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

Dmknerr

Views

5171

Build Author

Dmknerr

Views

5171

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

Chetan PM

Views

3772

Build Author

Chetan PM

Views

3772

Composer

Gantry style rigid build

A work in progress

One of my first projects might be cutting proper plates.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

Robert Huxford

Views

3935

Build Author

Robert Huxford

Views

3935

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7422

Build Author

Matt Barile

Views

7422

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Double trolley X and Z belt training

Total belt drive GT2

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

J-Wahl Dezign

Views

9107

Build Author

J-Wahl Dezign

Views

9107

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

Rich Bowen

Views

3815

Build Author

Rich Bowen

Views

3815

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Build Author

Robert E. Nee

Views

17301

Build Author

Robert E. Nee

Views

17301

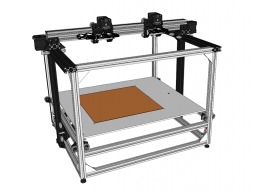

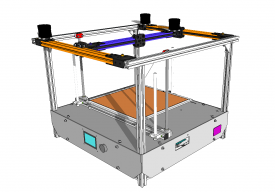

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Build Author

recoush

Views

9165

Build Author

recoush

Views

9165

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jonathon Duerig

Views

7163

Build Author

Jonathon Duerig

Views

7163

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

nschreiber0813

Views

5442

Build Author

nschreiber0813

Views

5442

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

THE LINK

Views

5045

Build Author

THE LINK

Views

5045

2020 First build.

Probably cheapest DIY build youl see.

Build Author

Tomas F Uribe

Views

5305

Build Author

Tomas F Uribe

Views

5305

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

Hisha

Views

4965

Build Author

Hisha

Views

4965

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Huub65

Views

9191

Build Author

Huub65

Views

9191

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

evgeny156

Views

7289

Build Author

evgeny156

Views

7289

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Jens Grabner

Views

4085

Build Author

Jens Grabner

Views

4085

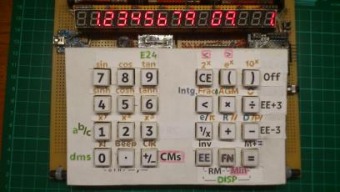

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

CNC Planning

Reusing parts to build a CNC - planning stage

Build Author

Fabio Orsi

Views

6905

Build Author

Fabio Orsi

Views

6905

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Build Author

megashub

Views

24089

Build Author

megashub

Views

24089

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Karan Singh Sisodia

Views

6253

Build Author

Karan Singh Sisodia

Views

6253

My Home made CNC

Home Made CNC Router from Scrape

Build Author

islahcnc

Views

4420

Build Author

islahcnc

Views

4420

islahcnc&design

I will post soon some more details.

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Build Author

JerryD

Views

5303

Build Author

JerryD

Views

5303

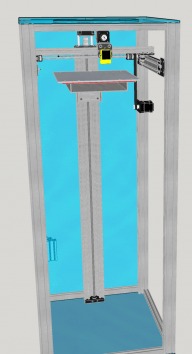

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

100w Laser Cutter Build Log

I rebuild my 2 meter tall 3D printer into a 100w laser cutter

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.