Build List

-

Active Filters:

in

Tool position setting Part II.

The method used for tool position setting is a matter of personal choice but this is what I do.

Build Author

adamcooks

Views

43426

Build Author

adamcooks

Views

43426

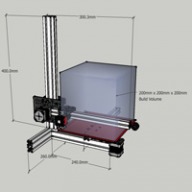

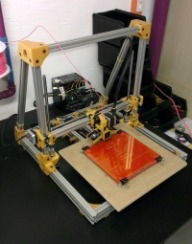

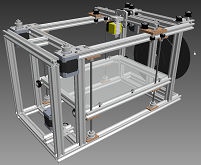

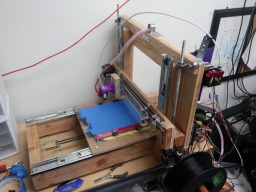

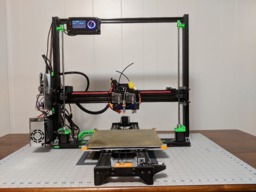

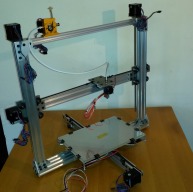

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Build Author

JWhitten

Views

14170

Build Author

JWhitten

Views

14170

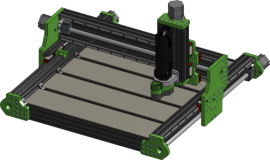

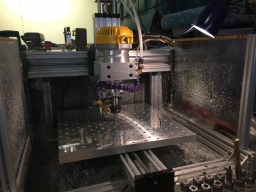

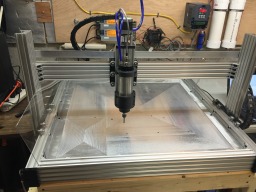

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

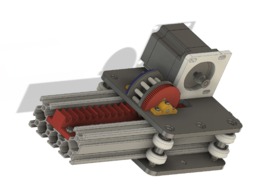

Improved CBM

Yet another build of an improved C-Beam Machine, improving stiffness, size, versatility, and strength without increasing costs much.

Build Author

Eric Jacobsson

Views

15495

Build Author

Eric Jacobsson

Views

15495

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

viktop

Views

18715

Build Author

viktop

Views

18715

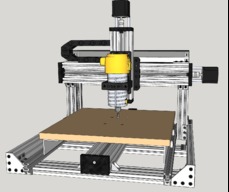

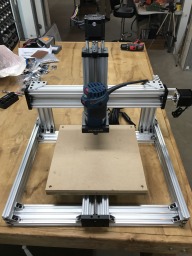

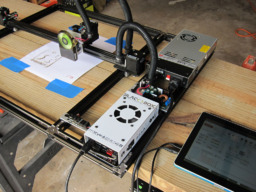

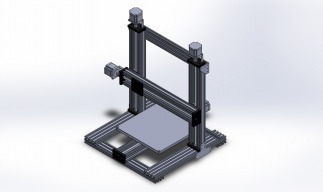

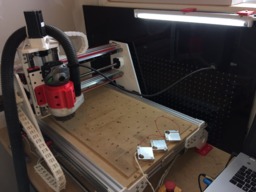

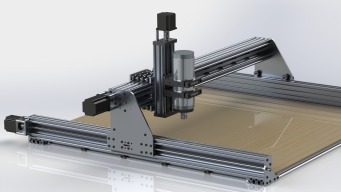

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

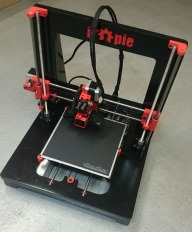

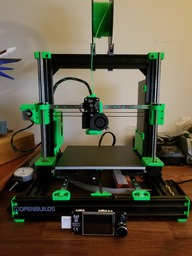

V-Baby CoreXY - Quality Engineered DIY 3d Printer

Easy to build - affordable opensource DIY CoreXY 3d Printer for fast reliable prototyping on your desktop - All wheels and V-Slots for smooth quick moves and opensource firmware on 8 or 32 bit controllers

Build Author

Frank Del Favero

Views

9824

Build Author

Frank Del Favero

Views

9824

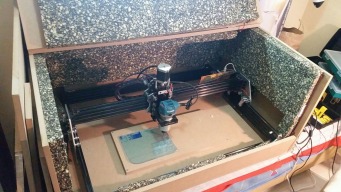

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

OpenBot

The aim of this OpenBot build, was to make a 3d Printer that was easy to build with minimal tools and using of the shelve parts from Openbuilds.

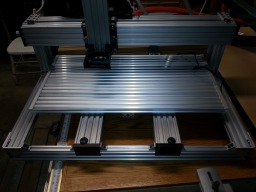

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

Bud Griffin

Views

11674

Build Author

Bud Griffin

Views

11674

BF3D OX (Big Freakin' 3D OX)

This is my latest printer build. The second printer I've built using V-Slot.

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

Build Author

pedrofernandez

Views

15336

Build Author

pedrofernandez

Views

15336

The Franken Forty

This is a K40 machine conversion!!

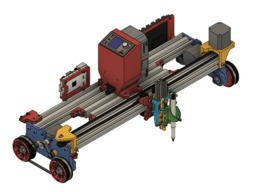

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Vulcan Pro V1

A posi-drive leveling printer in 300x300x380mm format that easily breaks down for suitcase size shipping.

Build Author

wackocrash5150

Views

19799

Build Author

wackocrash5150

Views

19799

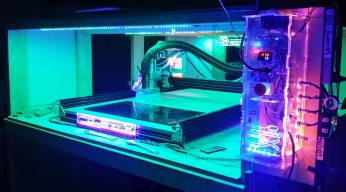

45W CO2 Laser Build

A co2 laser build that is heavily inspired and based quite a bit off Pedro Fernandez' 50w co2 laser build. This is my first build post so, bare with me.

Lautr3k RepRap

A 3D printer without belts, a print volume of 320x320x260mm, obviously the V-Slot as linear guide! and a maximum of printed pieces.

Build Author

Peter Oakes

Views

44391

Build Author

Peter Oakes

Views

44391

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Build Author

Mark Carew

Views

36721

Build Author

Mark Carew

Views

36721

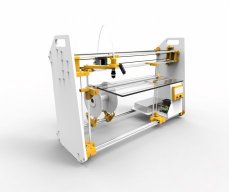

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

pedrofernandez

Views

12219

Build Author

pedrofernandez

Views

12219

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

HuguesP

Views

9287

Build Author

HuguesP

Views

9287

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Build Author

Mark Carew

Views

78047

Build Author

Mark Carew

Views

78047

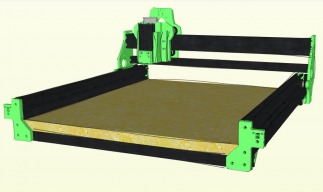

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

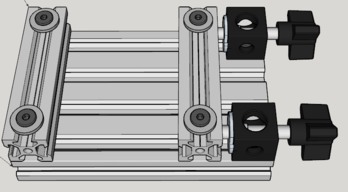

RRP - Roller Rack Pinion System

Current progress uses existing openbuilds bearings, but also uses 8mm shafts (custom)

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

that-jim

Views

12107

Build Author

that-jim

Views

12107

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

Rob Taylor

Views

26613

Build Author

Rob Taylor

Views

26613

DSLR Video Slider

A simple 1500mm V Slot camera slider for timelapse and possibly video with an Arduino Uno controlling a Pololu A4988 driving an OpenBuilds NEMA 17 stepper, and triggering the camera.

Build Author

UltiBots

Views

33080

Build Author

UltiBots

Views

33080

Mini Kossel V-Slot 3D Printer

This build is very straight forward. The design is simple. There is a great support community for Delta 3D printers.

iTopie RepRap - 3D Printer

A stable and strong 3D printer made of 16mm MDF and machined on my OX.

Build Author

inhan

Views

21434

Build Author

inhan

Views

21434

Openbuilds rovo laser mini(오픈빌드)

laser mini 20 * 40 OPENBUILDS base frame.(크기 412x455mm) laser mini 20*40 기본프레임입니다. 기존 여러부품을 사용한 제품보다 부품수를 줄이면서 최소한의 단가를 뽑을려고 디자인했습니다.. 기존대비 부품수 절반에 단가도 절반을 줄이면서 최적의성능을 내려합니다.

Build Author

alex_b

Views

17308

Build Author

alex_b

Views

17308

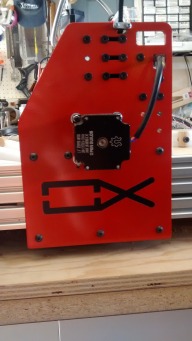

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Build Author

mytechno3d

Views

25489

Build Author

mytechno3d

Views

25489

SLA (Resin) 3D Printer

SLA LCD 3D Printer ( 8.9'' LCD screen )

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

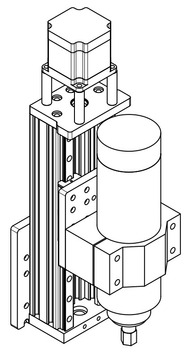

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

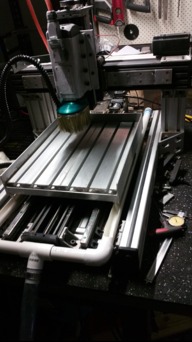

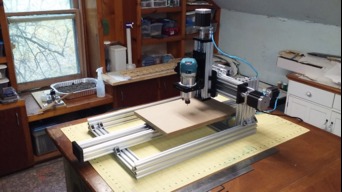

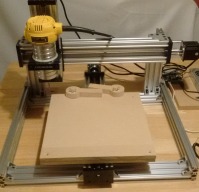

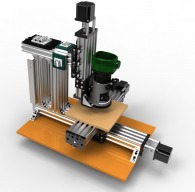

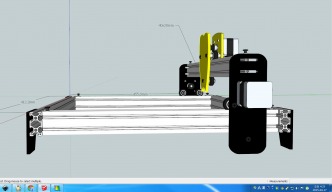

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

jtaggard

Views

37406

Build Author

jtaggard

Views

37406

Modular DIY CNC Machine

This modular CNC machine is based on the OpenBuilds ACRO System, however I wanted something that did more than just laser engrave. So I designed my machine using the same style as the ACRO but with some upgrades such as an actual Z-axis and the ability for multiple tool attachments.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

Mark Carew

Views

85493

Build Author

Mark Carew

Views

85493

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Build Author

mytechno3d

Views

15581

Build Author

mytechno3d

Views

15581

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

Build Author

Scott Martinez

Views

12255

Build Author

Scott Martinez

Views

12255

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

Kyo

Views

28796

Build Author

Kyo

Views

28796

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

Build Author

Ronald van Arkel

Views

16660

Build Author

Ronald van Arkel

Views

16660

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

Build Author

dmasters

Views

8272

Build Author

dmasters

Views

8272

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Hydraulic lifting table

I started this project without drawing. in itself this went fine with some minor adjustments. My profession is machine builder that might make it a little easier. I still enjoy it every day.

Build Author

nc3dpw

Views

24465

Build Author

nc3dpw

Views

24465

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

BinaryConstruct

Views

10269

Build Author

BinaryConstruct

Views

10269

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Mark Rehorst

Views

10223

Build Author

Mark Rehorst

Views

10223

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

James Evanko

Views

7355

Build Author

James Evanko

Views

7355

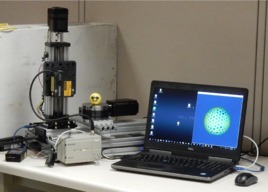

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Minimalist Laser Platform

Minimalist laser platform built with Makerlink connectors and modified Nema 17 stepper mounts used as gantry plates.

18x36x16 Inch 3D Printer - Work in progress

Tough 3D Printer using OpenBuilds Parts!

Build Author

ajdubs

Views

5635

Build Author

ajdubs

Views

5635

A custom arcade

This is an arcade "cabinet" of sorts built almost entirely from OpenBuilds extrusions. Save for a few 3d printed parts, the electrical components, the acrylic panels, and the monitor mount, every component was purchased from the OpenBuilds part store.

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Build Author

Ryan155

Views

14135

Build Author

Ryan155

Views

14135

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

Mark Carew

Views

14850

Build Author

Mark Carew

Views

14850

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Build Author

SlyClockWerkz

Views

16955

Build Author

SlyClockWerkz

Views

16955

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

OKMI 3d Printer

OKMI 3d Printer based on CoreXY

Build Author

ymilord

Views

22327

Build Author

ymilord

Views

22327

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

Rob Taylor

Views

20461

Build Author

Rob Taylor

Views

20461

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Pelican Case 3D Printer

A portable 3D Printer that can flat pack into a hard carry case

My 1st Build - Delta Printer with 3 filament hot end

The build area will be fully enclosed. I anticipate using primarily ABS, and have interest in the soluble support materials as well. The main components to date include: OPENBUILDS - 3 x C-Beam™ Linear Actuator Bundle, 1000 mm, w/ Included NEMA23 Motor) Extruders (3) - [Sintron] 1.75mm Mini All Metal MK8 Extruder Hot End - reprap diamond Control board - RUMBA Stepper drivers - DRV8825 StepStick Power supply - eTopxizu 12v 30a

Build Author

ymilord

Views

12761

Build Author

ymilord

Views

12761

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

Bridge Port

Views

9324

Build Author

Bridge Port

Views

9324

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Laser engraving machine

Second better project, high durable mainframe, silent work, non vibration.

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Kyo

Views

16283

Build Author

Kyo

Views

16283

Stinger Laser

3-Axis CNC Laser Engraver running grbl 1.1 in laser mode and Laserweb4.

Build Author

Apothus

Views

22550

Build Author

Apothus

Views

22550

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

Build Author

Andreas Bockert

Views

12074

Build Author

Andreas Bockert

Views

12074

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

crypt-tek

Views

10086

Build Author

crypt-tek

Views

10086

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

A Rolling Plotter

To build a simple plotter that rolls along the length of large paper, foam core or other flat objects.

Build Author

Sergio Di Ventura

Views

9376

Build Author

Sergio Di Ventura

Views

9376

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

2SIsurf

Views

6647

Build Author

2SIsurf

Views

6647

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

AK-Creation

Views

22617

Build Author

AK-Creation

Views

22617

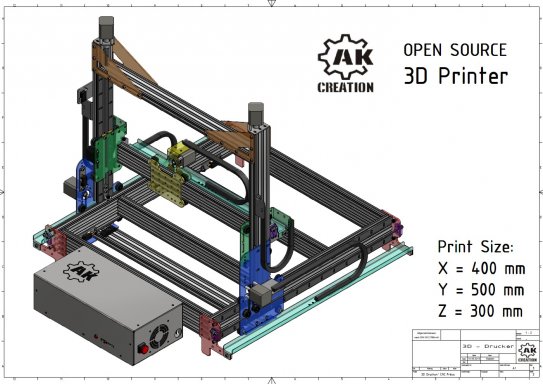

3D Printer - Big Size

I creat a open source 3D Printer to print big things. Print size: 400x500x300 mm. You can download the Drawing in PDF and in Inventor 2013 format. The unwinding drawings are also included. I take some detail photos for a better understanding.

Build Author

pdesigns

Views

29106

Build Author

pdesigns

Views

29106

RepRap Tuga

This is a work in progress(not printing yet). Expect this instructions to grow with time, but for now it is mainly interesting for those who want to take part in developing this printer.

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

Build Author

Sheepdog

Views

26891

Build Author

Sheepdog

Views

26891

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Build Author

M^3

Views

22081

Build Author

M^3

Views

22081

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

Build Author

Hytech2k

Views

33990

Build Author

Hytech2k

Views

33990

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

BAFP 3D Printer

A New Core XY Printer build. BAFP stands for Big And Fast Printer. It will be awesome !!

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

James Archer

Views

14486

Build Author

James Archer

Views

14486

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Build Author

Sonny Lowe

Views

7036

Build Author

Sonny Lowe

Views

7036

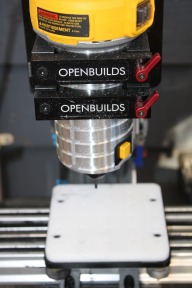

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

3D PrintBot 500x500x500

Large scale True 500x500x500 build volume 3D printer.

Build Author

chenderson

Views

12899

Build Author

chenderson

Views

12899

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

Build Author

pek

Views

6530

Build Author

pek

Views

6530

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

Build Author

Rob Mahan

Views

13893

Build Author

Rob Mahan

Views

13893

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

Glenn Weston

Views

11518

Build Author

Glenn Weston

Views

11518

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.