Build List

Build Author

Fabio Orsi

Views

7095

Build Author

Fabio Orsi

Views

7095

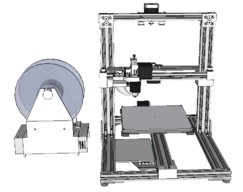

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

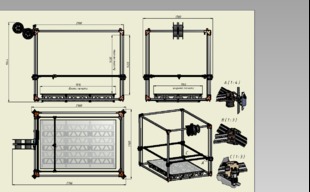

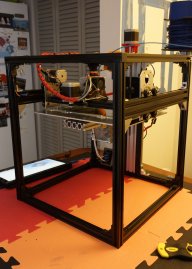

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

V-Slot MAME cabinet

A minimalist MAME "cabinet" made from extrusion.

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Build Author

Carl van Heezik

Views

8752

Build Author

Carl van Heezik

Views

8752

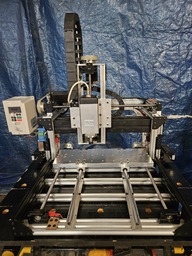

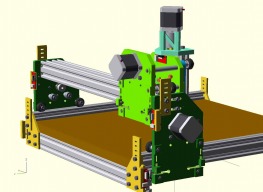

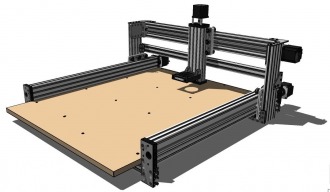

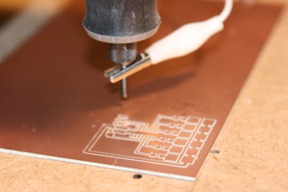

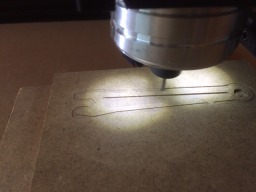

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

cory stafford

Views

4889

Build Author

cory stafford

Views

4889

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

Lindsey Lewis

Views

9238

Build Author

Lindsey Lewis

Views

9238

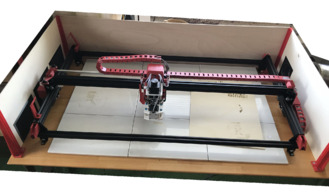

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

CandlerCustoms

Views

5817

Build Author

CandlerCustoms

Views

5817

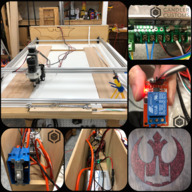

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

Camvec

Views

6444

Build Author

Camvec

Views

6444

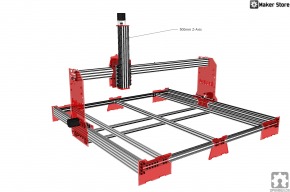

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

TurfnSurf

Views

6354

Build Author

TurfnSurf

Views

6354

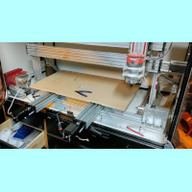

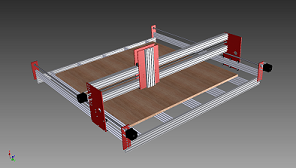

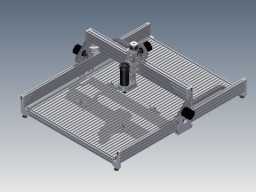

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

crnrstndes

Views

4401

Build Author

crnrstndes

Views

4401

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Makerparts Mpro Slider System

Makerparts.ca MPro Camera Slider System

Build Author

stepper

Views

4743

Build Author

stepper

Views

4743

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

Build Author

Hilleke

Views

8068

Build Author

Hilleke

Views

8068

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

Build Author

rob4cnc

Views

4139

Build Author

rob4cnc

Views

4139

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

James Evanko

Views

5116

Build Author

James Evanko

Views

5116

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Build Author

Craig Hollabaugh

Views

5169

Build Author

Craig Hollabaugh

Views

5169

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Vegard Humlen

Views

5242

Build Author

Vegard Humlen

Views

5242

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

Build Author

Christian James

Views

10576

Build Author

Christian James

Views

10576

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Jay Almers

Views

8435

Build Author

Jay Almers

Views

8435

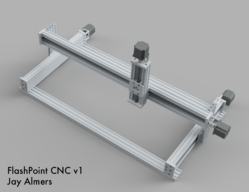

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Indoor Drumline Props

Triangular Towers

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

Vacuum laser table

Large 10’x6’ vacuum table made from steel tubing and 1/4 inch steel plate

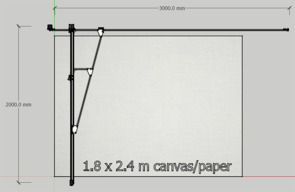

SB Plotter

Large floor or wall mounted plotter design.

V-Slot 2020 EggBot

To build a simple EggBot

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

Piggy back engraver for ShopBot

Built from leftover T-Slot extrusions plates and hardware from other defunct projects.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Build Author

Quinnthouzand

Views

4262

Build Author

Quinnthouzand

Views

4262

Mustardo - The Mustard Bot

The goal for this bot is to lay down mustard on sausages and burger patties in a smooth and sexy way that looks good for the camera.

Build Author

Jason @ MCC

Views

13700

Build Author

Jason @ MCC

Views

13700

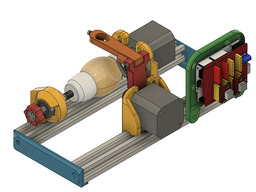

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

Build Author

OpenBuilds

Views

27690

Build Author

OpenBuilds

Views

27690

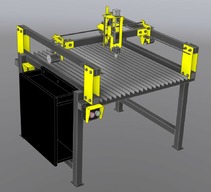

OpenBuilds Table Series

The OpenBuilds Table Series offers a modular table structure that grows with your needs.

Phlat Printer 3 meets Open Builds

I will go over the attachments for the PP3 Z axis. soon. Before any thing else .You need to know the first PP3 ,used SKP 7 and Mach 3. Later on they used CNC USB.

Bessy 4x4

I found this to be a very fun exercise in building Bessy and will continue to improve her in the future.

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

1.3m x 1.3m RF laser cutter

RF 100w laser cutter build, aluminium extrusion

Laser engraver

CNC laser with GRBL firmware on board

Build Author

Jacob Christiansen

Views

7644

Build Author

Jacob Christiansen

Views

7644

ACRO 1010 with custom Z axis

This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting.

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

The Beast

1000mm x 1000mm linear rails, double gantry, build in Process... more to come

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Plasma Table 006

Fast, inexpensive, near-zero maintenance, and 2+ years of near-daily use.

Monster-not-so-mini-mill

My Minimill hit the gym, and isn't so mini anymore

Build Author

Damian V-SLOT Poland

Views

4143

Build Author

Damian V-SLOT Poland

Views

4143

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Heavy Metal

CNC Mill built for cutting metal.

cnc back stop for brake press

back stop build

Build Author

David E. Flores E.

Views

7134

Build Author

David E. Flores E.

Views

7134

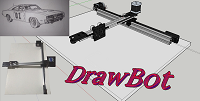

DaveWare DrawBot

Turning my prototypes into real objects, it will be required a great amount of drawings, A LOT. Therefore, against the ink costs raise price push me to think in a way to draw models, blueprints, etc. at very, VERY low cost. This is where my DrawBot was born

Edge Carve MK1

I have created a video showing the Edger Carve features https://www.youtube.com/watch?v=v5mV_6vyxAA&t=3s

Mortiser

A work-in-progress build using OpenBuilds parts to create a mortising jig.

Reducing leadscrew whip

The video demonstrates a practical device to reduce whip

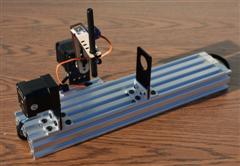

DIY GoPro Camera Slider

A compact portable DIY camera slider for time lapse photography using a GoPro.

Cubic 3D Printer

I've made a 3D printer

Build Author

John J Talavera

Views

7710

Build Author

John J Talavera

Views

7710

Rotomolder

A simple low cost rotomolder.

Build Author

CubeSpawn

Views

16328

Build Author

CubeSpawn

Views

16328

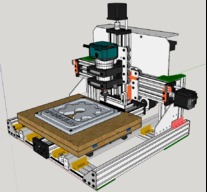

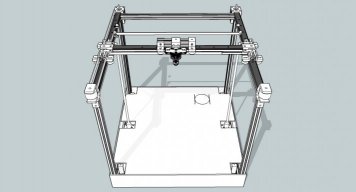

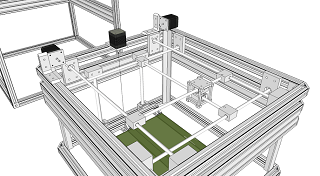

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Build Author

CubeSpawn

Views

20003

Build Author

CubeSpawn

Views

20003

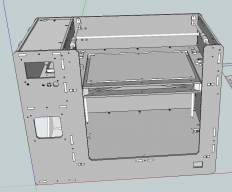

CubeSpawn Ultimaker 3D Printer Module

This 3D printer is an implementation of the Ultimaker 3D printer Using the Modular approach, many of the parts from the CubeSpawn 3 axis mill translate straight across into this design, so adding new concepts should go quicker

Build Author

Mohsen Abbasi

Views

5439

Build Author

Mohsen Abbasi

Views

5439

True Human Prosthesis

Prosthesis is functionality and emotion!

Build Author

MechEng

Views

16213

Build Author

MechEng

Views

16213

Generic Rigid 3D Printer (Currently on 1st Revision!)

Rigid 3d printer with more than enough room for dual extruders. Easily expandable platform.

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Aluminium OX - Canada

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

Build Author

CreativeTools

Views

9983

Build Author

CreativeTools

Views

9983

Universal stand-alone filament spool holder (Fully 3D-printable)

A practical rotating and stand-alone spool holder which fits any filament extrusion 3D-printer. Several base files provided which make it fit different extruded aluminium profiles.

Birdie CNC

OpenBuilds CNC 500x500

Aluminium Router From Dubai

Another modification on the OX

Build Author

Hytech2k

Views

7136

Build Author

Hytech2k

Views

7136

Micro Ox 2 x 2

Micro Ox Build

OXilla - a 3ft x 3ft CNC Router/Mill - Goals are strength, power and speed

This will be an ongoing log as I build this machine. Name change by popular demand - at least a couple of us. :)

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Build Author

Donald D. Parker

Views

5777

Build Author

Donald D. Parker

Views

5777

BABE - CanUSA Blue OX, bigger than the average OX

This is a basic description of my OX-like build of Babe, Paul Bunyan's Blue Ox. It is a work in progress. The idea has been germinating for about 4 years, with several twists and turns and false starts along the way.

Build Author

inhan

Views

6381

Build Author

inhan

Views

6381

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

Build Author

openhardwarecoza

Views

9418

Build Author

openhardwarecoza

Views

9418

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Small drill press fence

A small build using some small vslot scrap piece which shows the versatlity of the v-slot system

Build Author

Tinker

Views

9232

Build Author

Tinker

Views

9232

Kitchen Space Saver

The frame is made from all open builds parts, add the rubber feet and pads for the glass. The glass is clear 12" x 16" x 1/4" with a polished edge. A light basket slides on the countertop.

Build Author

Justin Butler

Views

9685

Build Author

Justin Butler

Views

9685

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

C-Beam bellows

Making a bellows to cover a C-beam to prevent swarf from gumming up the works.

Build Author

Steve Marsh

Views

5881

Build Author

Steve Marsh

Views

5881

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

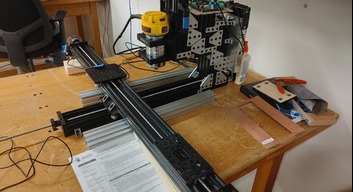

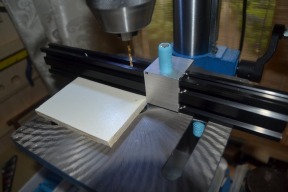

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

C-Beam-McDrew

After seeing different egg bots designs, I decided to incorporate my own design.

Expanded Routy using 290 build instructions

Using the Routy290 build and an awful lot of help from puntoMX, this machine has been expanded in the X and Y axis. My first build, I'm learning a lot about all of this. I've had to disassemble parts of this thing many times due to forgetfulness, but that's ok. Also, I've forgotten to take constant pictures throughout the build.

Build Author

Charles Roseberry

Views

5189

Build Author

Charles Roseberry

Views

5189

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

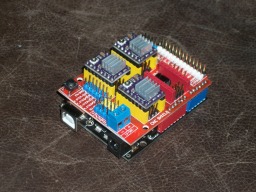

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

Build Author

andrizzle

Views

7190

Build Author

andrizzle

Views

7190

Printer1

Open source 3D printer with very powerful heated bed and light weight x axis design. Full source repository can be found here: https://github.com/a-drizzle/Printer1

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

CO2 laser cutter

A build which is based on a metal frame and aluminium plate which I salvaged from a skip. The frame is sized to hold 19" rack units so I'll build my control box into a 3U rack unit (also salvaged). The area available for the build is 700x1200mm. I'll sling a 60W CO2 tube under the base, the beam path will be initially upward into the enclosure.

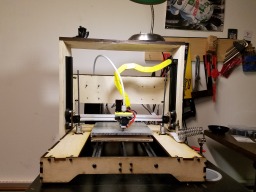

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Build Author

Simon Rafferty

Views

7762

Build Author

Simon Rafferty

Views

7762

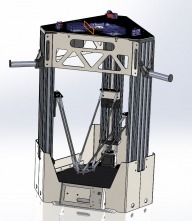

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators