Build List

-

Active Filters:

nt

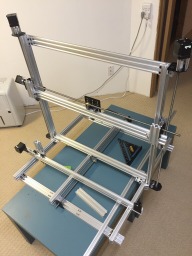

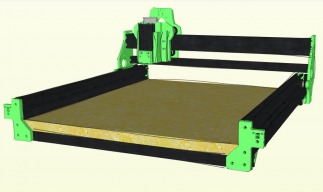

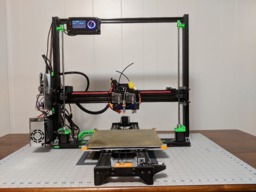

OpenBuilds BCN 900

All's good for assembly, testing coming up soon

Build Author

rusirius

Views

16868

Build Author

rusirius

Views

16868

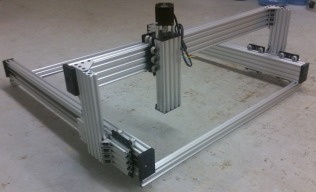

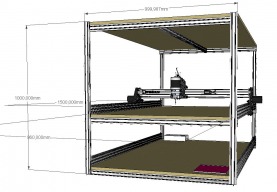

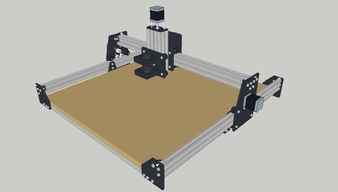

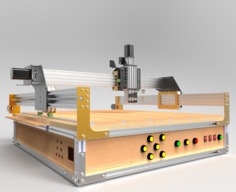

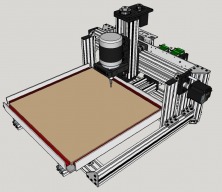

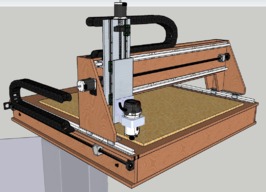

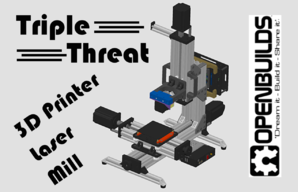

MultiBOT LRP

A CNC platform designed with swapable heads to do laser engraving/etching/cutting, routing and milling, as well as 3D printing.

Build Author

Spark Concepts

Views

16625

Build Author

Spark Concepts

Views

16625

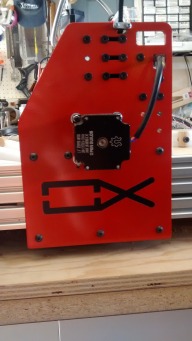

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

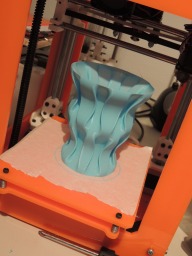

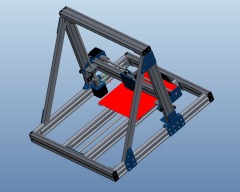

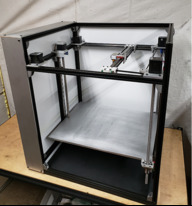

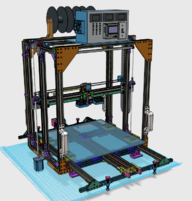

Dash X Direct, Cross-Beam 3d Printer

This is the next version of Dash, now operating much closer to its potential. Please message me if you need anything, such as Simplify3D settings, material information, design intent etc. Since the Pack-and-Go zip file is fairly large (120mB), here is a link where it can be downloaded: https://drive.google.com/file/d/1Q3ygyo_tTrB4UYIV62_wtCSCbWuE3krT/view?usp=sharing Note: I use Solidworks 2022, acquired through their Solidworks for Makers program (check it out!). A super deal at $100/yr

Build Author

Ronald van Arkel

Views

16600

Build Author

Ronald van Arkel

Views

16600

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

Bobnet

Views

16441

Build Author

Bobnet

Views

16441

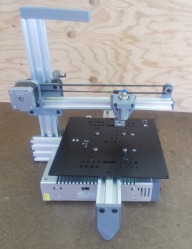

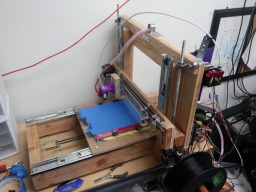

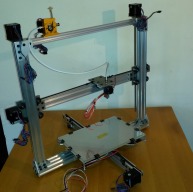

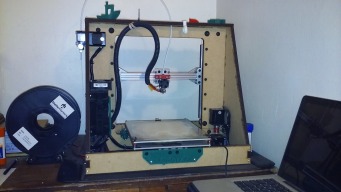

Oversize ShapeOko as a 3D printer.

Converting a ShapeOKO into a 3D printer.

Build Author

TomH

Views

16339

Build Author

TomH

Views

16339

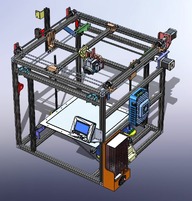

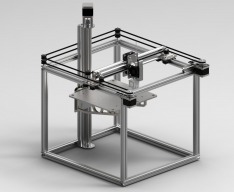

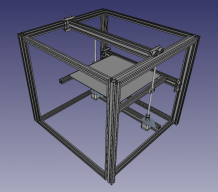

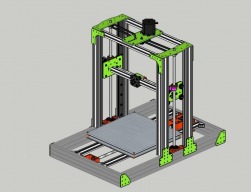

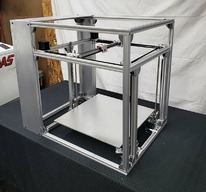

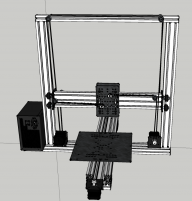

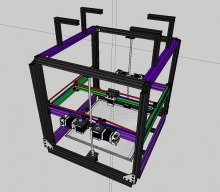

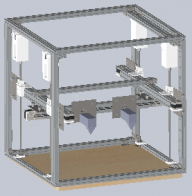

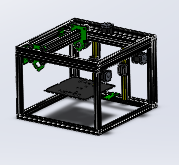

H-Bot CoreXY Cube with Fixed Build Plate

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

Build Author

brw_racing

Views

16216

Build Author

brw_racing

Views

16216

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

MakerSL MSL-6 DLP 3D Printer

This will be a DLP 3D Printer designed around an Openbuilds Frame and rail system. It will be a collaborated effort between myself and Ben Smith. We will be building two prototypes.

Build Author

mytechno3d

Views

16181

Build Author

mytechno3d

Views

16181

Cut To Length Machine

A Cut To Length machine controlled by computer

Build Author

Kyo

Views

16175

Build Author

Kyo

Views

16175

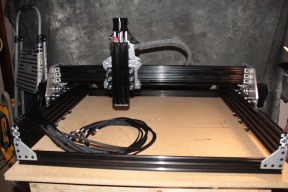

Stinger Laser

3-Axis CNC Laser Engraver running grbl 1.1 in laser mode and Laserweb4.

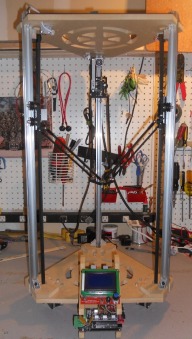

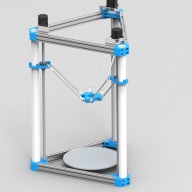

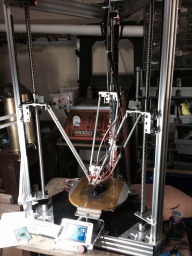

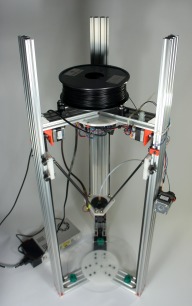

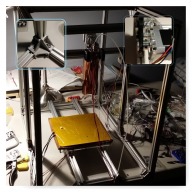

V-slot and MDF DeltaBot

This is a deltabot 3D printer build using CNC routed MDF and v-slot rails. Full description found in instructables.com.

Build Author

Nwrgordon

Views

15886

Build Author

Nwrgordon

Views

15886

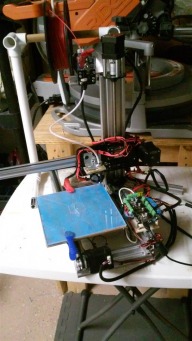

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Build Author

MechEng

Views

15833

Build Author

MechEng

Views

15833

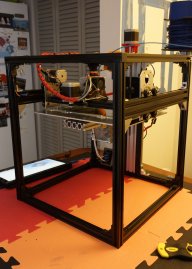

Generic Rigid 3D Printer (Currently on 1st Revision!)

Rigid 3d printer with more than enough room for dual extruders. Easily expandable platform.

Build Author

shanehooper

Views

15824

Build Author

shanehooper

Views

15824

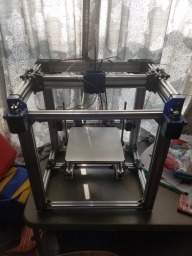

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Janis93

Views

15638

Build Author

Janis93

Views

15638

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Mini D-Bot

A smaller version of a standard D-bot. Smaller to fit better in my workable area and to fit my vision for the printer.

spunks.cam

Design of a multifunctional CNC machine.

Cubic 3D Printer

I've made a 3D printer

Build Author

Rick Holder

Views

15397

Build Author

Rick Holder

Views

15397

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

Build Author

north90

Views

15127

Build Author

north90

Views

15127

OpenSampler: OpenSource autosampler for use in laboratory

An open source autosampler to be used in laboratories for the automated analysis of gas or liquid samples.

BotMaker

This is a work in progress 3D printer Dimensions are 230x230x340mm height. Print dimensions are: 135x135x160mm. Prototype has a bowden extruder with a J-head hotend. Assembly instructions: http://reprapstyle.blogspot.pt

TesseractXY (MendelMax 1.5 version)

History about making 3d printer.

Build Author

David Bunch

Views

14928

Build Author

David Bunch

Views

14928

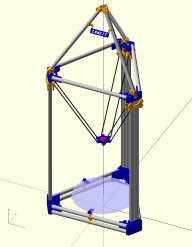

Emmett-Delta

Delta 3d Printer using 3/4" Electrical Metal Tubing (EMT) for Horizontals & 2060 V-Slot for the Verticals and adding a tetrahedron at the top.

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

Build Author

AK-Creation

Views

14918

Build Author

AK-Creation

Views

14918

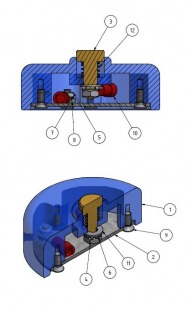

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

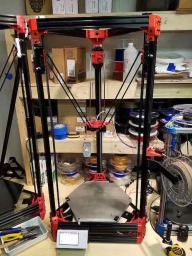

Delta 3d Printer

I am going to use this as a build log for my delta 3d printer build. I have access to a MakerBOT to print some of the parts. I am still finishing up a few of the design elements but the idea is to have a rigid unit to eliminate deflection in components and maintain accuracy.

Build Author

Mark Carew

Views

14782

Build Author

Mark Carew

Views

14782

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Build Author

Metalguru

Views

14652

Build Author

Metalguru

Views

14652

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

David Arroyo

Views

14630

Build Author

David Arroyo

Views

14630

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Build Author

GinoTheCop

Views

14597

Build Author

GinoTheCop

Views

14597

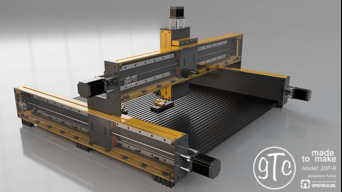

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

Project Hopeless

Views

14441

Build Author

Project Hopeless

Views

14441

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Build Author

James Archer

Views

14402

Build Author

James Archer

Views

14402

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Build Author

Savvas

Views

14400

Build Author

Savvas

Views

14400

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

V Rail 3D printer

My version a Cartesian style 3d printer, an attempt to eliminate frame vibration and movement and to use up materials left over from other projects.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

Build Author

andrew Adsit

Views

14029

Build Author

andrew Adsit

Views

14029

OX Cable Management, Electronics Case, E-Stops

750mm x 750mm OX build, xPro V2 controller, 400W Spindle with PWM controller.

Build Author

Ryan155

Views

13968

Build Author

Ryan155

Views

13968

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

Sword66

Views

13956

Build Author

Sword66

Views

13956

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

Build Author

Venturebit

Views

13736

Build Author

Venturebit

Views

13736

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

Build Author

Rob Mahan

Views

13706

Build Author

Rob Mahan

Views

13706

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

dddman

Views

13643

Build Author

dddman

Views

13643

Prusa i3 (Acrylic frame with OB rods)

The Prusa i3 (iteration 3) is the newest and most current 3D Printer design by RepRap Core Developer Prusajr (source: http://reprap.org/wiki/Prusa_i3)

Build Author

KBill

Views

13516

Build Author

KBill

Views

13516

MIY OLY Delta Printer

Mag arm deltabot with laser cut carriages and connectors.

blackcat3d printer

in construction ! chassis vslot 80x20 & 20x20 & 60x80 (Z) home made plates with whells polycarbonate build volume environ, 750x300x200 2 ed3d v6 volcano nozzles 0.8mm & 0.6 + titan extrudeurs rumba bord + auto levelling ip camera home made heat bed aluminium 5mm + glass + heat air chamber 6 doors plexiglass......

Build Author

Bobnet

Views

13335

Build Author

Bobnet

Views

13335

Rackmount + OpenRail

OpenRail attached to a 19" rackmount 15U box.

Build Author

cbordeleau

Views

13222

Build Author

cbordeleau

Views

13222

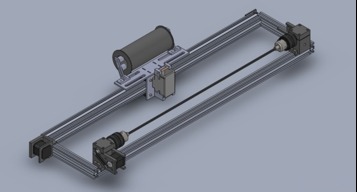

OpenBuilds C-Beam Double Slider

This slider uses an 500mm OpenBuilds C-beam and the design is such that the effective length of the slider is slightly less then twice the length of the C-Beam. It can be used both motorized or not.

Filament winder ( carbon fiber )

Carbon fiber filament winder

Build Author

Jason Moore

Views

13043

Build Author

Jason Moore

Views

13043

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

SimplrBot

This is a simple, yet rugged design, weighing only 6 lbs and with 13x13x14" volume with a 8x8x6" build area. While assembly is pretty simple, the small size and rigidity of the design make shipping assembled printers attractive.

Build Author

nickchnv

Views

12552

Build Author

nickchnv

Views

12552

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

Build Author

Kyo

Views

12534

Build Author

Kyo

Views

12534

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

Build Author

j0achim

Views

12317

Build Author

j0achim

Views

12317

CoreXY - e3d inspired

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Build Author

GDanger117

Views

12313

Build Author

GDanger117

Views

12313

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

obmilllivebuild

Views

12276

Build Author

obmilllivebuild

Views

12276

Live OpenBuilds MiniMill -> MiniPrint/Laser Conversion Demo @ MRRF2019

Transformation of an OpenBuilds Mini Mill into a convertible 3D printer / CNC mill with interchangeable tooling. Maybe a bonus conversion TBD.

Build Author

Martin Bogomolni

Views

12255

Build Author

Martin Bogomolni

Views

12255

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

3D PrintBot 500x500x500

Large scale True 500x500x500 build volume 3D printer.

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

Build Author

Scott Martinez

Views

12148

Build Author

Scott Martinez

Views

12148

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Vulcan Pro V1

A posi-drive leveling printer in 300x300x380mm format that easily breaks down for suitcase size shipping.

My 1st Build - Delta Printer with 3 filament hot end

The build area will be fully enclosed. I anticipate using primarily ABS, and have interest in the soluble support materials as well. The main components to date include: OPENBUILDS - 3 x C-Beam™ Linear Actuator Bundle, 1000 mm, w/ Included NEMA23 Motor) Extruders (3) - [Sintron] 1.75mm Mini All Metal MK8 Extruder Hot End - reprap diamond Control board - RUMBA Stepper drivers - DRV8825 StepStick Power supply - eTopxizu 12v 30a

Build Author

Anthony Bolgar

Views

12017

Build Author

Anthony Bolgar

Views

12017

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

mirage335

Views

11976

Build Author

mirage335

Views

11976

FlexReplicator

Multi-tool 3D printer, laser cutter, and CNC mill.

Build Author

OpenBuilds

Views

11815

Build Author

OpenBuilds

Views

11815

Swing Arm

Simple Swing Arm Build for the Modular Table Series. Create a simple vacuum swing arm that swings over your machine keeping your vacuum hose and router cord, etc. up and out of the way

Build Author

sw3Dp

Views

11796

Build Author

sw3Dp

Views

11796

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Build Author

Joe Garritano

Views

11636

Build Author

Joe Garritano

Views

11636

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Build Author

Scotty Orr

Views

11621

Build Author

Scotty Orr

Views

11621

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

David Florian

Views

11578

Build Author

David Florian

Views

11578

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Build Author

Beam

Views

11566

Build Author

Beam

Views

11566

DIY Flywheel Camera Slider

My take on a non affordable slider.

Build Author

Glenn Weston

Views

11407

Build Author

Glenn Weston

Views

11407

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Ez3D - Phoenix 3D Printer Build

This is my 1st submission to openbuilds.com and my 1st venture into building a 3D Printer. The Phoenix 3d Printer is a kit from Ez3D, a company based out of Colorado, started and backed by successful Kick-starter and IndieGogo campaigns. The Phoenix 3d Printer kit is currently backlogged 10 to 12 weeks which means quite a wait. I will be chronicling my experience with this kit as I get it done.

Build Author

jjcolletta

Views

11192

Build Author

jjcolletta

Views

11192

First 3d build

I am building a simple home brewed printer. I have a background in industrial automation so I figured how hard could this be. The mechanical build was pretty smooth as was the electrical side. Now just getting plastic out the hotend is my stopping point.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Build Author

Sonny Lowe

Views

10854

Build Author

Sonny Lowe

Views

10854

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

Build Author

Naomi Wu

Views

10787

Build Author

Naomi Wu

Views

10787

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Darren Ditto

Views

10673

Build Author

Darren Ditto

Views

10673

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Build Author

UltiBots

Views

10551

Build Author

UltiBots

Views

10551

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

Build Author

Kaarbble

Views

10393

Build Author

Kaarbble

Views

10393

Kaarbble Nylon Bot

We plan experiment on nylon 3 D printing;

TABLE OX Router/3D-Printer

OX MultiMachine

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

BinaryConstruct

Views

10203

Build Author

BinaryConstruct

Views

10203

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

ALUMNO v1

It is a first draw of my future Printer/CNC cutter.PCB mill Still need to work more on it

Build Author

Philippe Bergeron

Views

10094

Build Author

Philippe Bergeron

Views

10094

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

Build Author

Bob Darrow

Views

10073

Build Author

Bob Darrow

Views

10073

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

crypt-tek

Views

10025

Build Author

crypt-tek

Views

10025

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.