Build List

-

Active Filters:

od

Build Author

Mark Carew

Views

220318

Build Author

Mark Carew

Views

220318

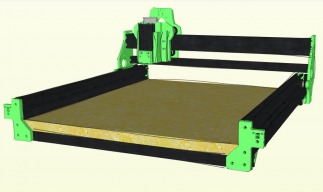

LEAD CNC 1010 (40" x 40")

The OpenBuilds Lead Machine takes us back to the roots of the OpenBuilds modular building system, and has proven itself as an adaptable design that can compete with any machine in its class!

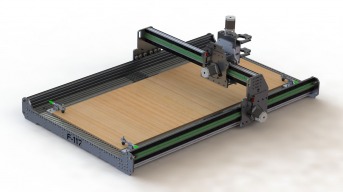

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Build Author

Mark Carew

Views

85984

Build Author

Mark Carew

Views

85984

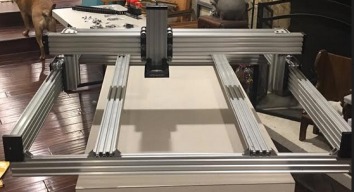

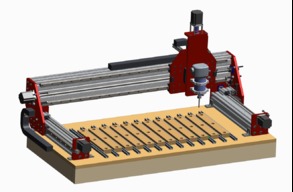

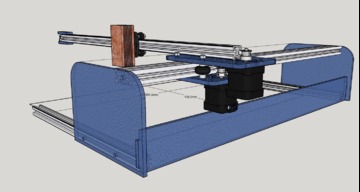

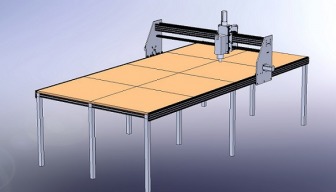

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Build Author

pek

Views

84996

Build Author

pek

Views

84996

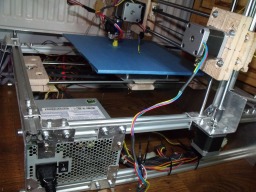

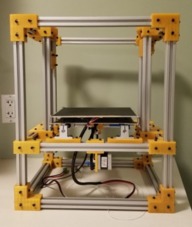

Prusa i3 Bear Upgrade V2

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Build Author

Mark Carew

Views

78504

Build Author

Mark Carew

Views

78504

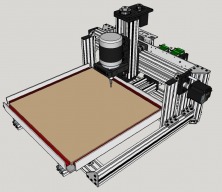

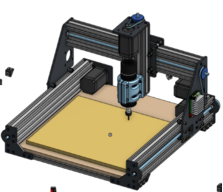

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

68993

Build Author

Mark Carew

Views

68993

High Z Mod for Lead CNC

The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router.

Build Author

Mark Carew

Views

55407

Build Author

Mark Carew

Views

55407

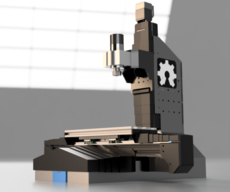

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Build Author

jtaggard

Views

37716

Build Author

jtaggard

Views

37716

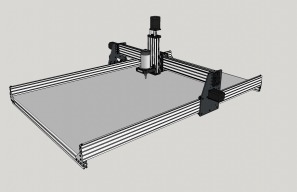

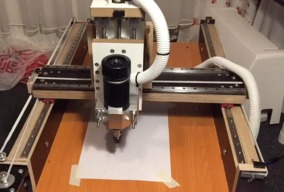

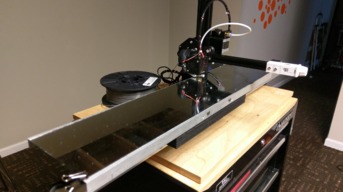

Modular DIY CNC Machine

This modular CNC machine is based on the OpenBuilds ACRO System, however I wanted something that did more than just laser engrave. So I designed my machine using the same style as the ACRO but with some upgrades such as an actual Z-axis and the ability for multiple tool attachments.

Build Author

Mark Carew

Views

34227

Build Author

Mark Carew

Views

34227

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

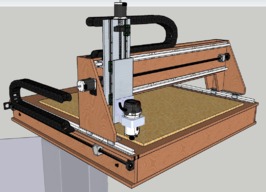

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

Build Author

Mark Carew

Views

28562

Build Author

Mark Carew

Views

28562

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Build Author

OpenBuilds

Views

27391

Build Author

OpenBuilds

Views

27391

OpenBuilds Table Series

The OpenBuilds Table Series offers a modular table structure that grows with your needs.

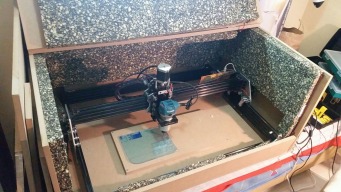

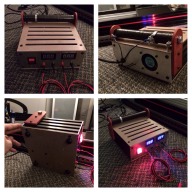

The Laserbox

A low cost and easy to build laser cutter based on 2.8w laser diode .

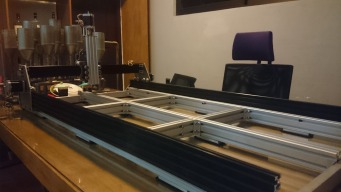

Large 1500x1000 Laser V

I am building a Laser cutter based off Robert Hummel's Laser V design.

Build Author

SecretSpy711

Views

22847

Build Author

SecretSpy711

Views

22847

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

ymilord

Views

22382

Build Author

ymilord

Views

22382

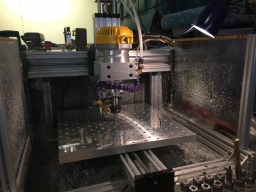

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

Rob Taylor

Views

20694

Build Author

Rob Taylor

Views

20694

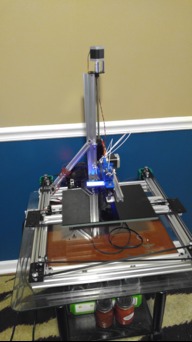

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

CubeSpawn

Views

19899

Build Author

CubeSpawn

Views

19899

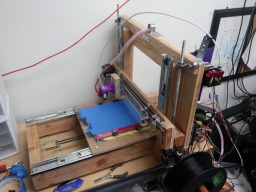

CubeSpawn Ultimaker 3D Printer Module

This 3D printer is an implementation of the Ultimaker 3D printer Using the Modular approach, many of the parts from the CubeSpawn 3 axis mill translate straight across into this design, so adding new concepts should go quicker

Build Author

William Niedermeyer

Views

19843

Build Author

William Niedermeyer

Views

19843

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Build Author

Mark Carew

Views

19765

Build Author

Mark Carew

Views

19765

V-Slot Modular Sit/Stand Desk

In this build we put together an awesome modular stand-up or sit down desk that is perfect of any home or office.

Build Author

viktop

Views

18965

Build Author

viktop

Views

18965

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Build Author

Kims3DIY

Views

18432

Build Author

Kims3DIY

Views

18432

Beamlazer Laser cutter CO2 100W

Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Then i decided to build my own laser, with some easier workflow and support for Windows 10. Since im still a student i have limited resources, so i will try too use scrap parts as much as possible. I will publish photos and updates during my build continously. Gladly taking advices from others.

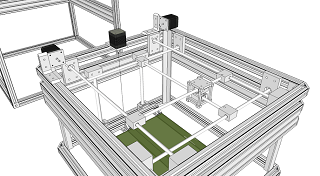

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

DIY anodizing power supply

How to make your own anodizing power supply on a budget

Build Author

Ronald van Arkel

Views

16759

Build Author

Ronald van Arkel

Views

16759

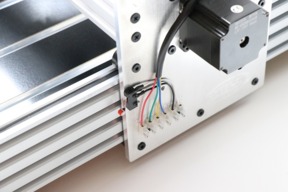

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

C-CNC

Views

16654

Build Author

C-CNC

Views

16654

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Build Author

Kyo

Views

16384

Build Author

Kyo

Views

16384

Stinger Laser

3-Axis CNC Laser Engraver running grbl 1.1 in laser mode and Laserweb4.

Build Author

CubeSpawn

Views

16213

Build Author

CubeSpawn

Views

16213

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Build Author

Eric Jacobsson

Views

15654

Build Author

Eric Jacobsson

Views

15654

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

Metalguru

Views

14918

Build Author

Metalguru

Views

14918

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Project Hopeless

Views

14664

Build Author

Project Hopeless

Views

14664

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Build Author

Rob Mahan

Views

14106

Build Author

Rob Mahan

Views

14106

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

dddman

Views

13743

Build Author

dddman

Views

13743

Prusa i3 (Acrylic frame with OB rods)

The Prusa i3 (iteration 3) is the newest and most current 3D Printer design by RepRap Core Developer Prusajr (source: http://reprap.org/wiki/Prusa_i3)

Adjustable Router Guide Template

This project is an adjustable router guide template made with 20x60 V-slot. It was meant as a less expensive and more user friendly alternative to commercially available units.

Build Author

JP Warnke

Views

12938

Build Author

JP Warnke

Views

12938

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

lekey

Views

12484

Build Author

lekey

Views

12484

Modular Desktop Vacuum Former

This is a small desktop vacuum former that can be connected to a shop-vac and an electric heat source (like a grill for instance). You can control the time each appliance stays turned on, and the vacuum is automatically turned on when the tray is placed on top of the model. The vacuum table is 20x20cm wide, and I've tested it mostly with 1mm thick PET sheets.

Build Author

BNMaker

Views

12236

Build Author

BNMaker

Views

12236

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

Build Author

reef

Views

12229

Build Author

reef

Views

12229

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

Joe Garritano

Views

11852

Build Author

Joe Garritano

Views

11852

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Build Author

dreys

Views

11523

Build Author

dreys

Views

11523

Was once a mini mill

Working progress.

Build Author

Naomi Wu

Views

10992

Build Author

Naomi Wu

Views

10992

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

Kyo

Views

10308

Build Author

Kyo

Views

10308

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

COMsulting

Views

10190

Build Author

COMsulting

Views

10190

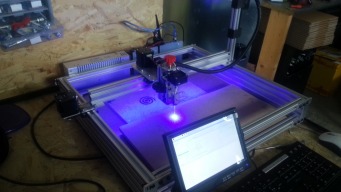

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

recoush

Views

9496

Build Author

recoush

Views

9496

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

openhardwarecoza

Views

9352

Build Author

openhardwarecoza

Views

9352

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Build Author

CWidt

Views

8817

Build Author

CWidt

Views

8817

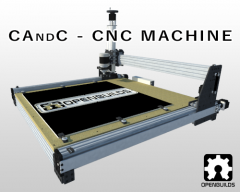

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Build Author

rcKeith

Views

8795

Build Author

rcKeith

Views

8795

USB Hot Wire CNC Foam Cutter

Build a Hot Wire CNC Foam Cutter with inexpensive 3d printer electronics.

Build Author

Mohsen Abbasi

Views

8449

Build Author

Mohsen Abbasi

Views

8449

Portable Foam Cutter

A portable foam cutter to make your forms everyware using a LiPo Battery.

Build Author

Julius

Views

8293

Build Author

Julius

Views

8293

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

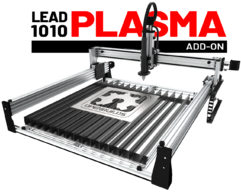

LEAD 1010 PLASMA Add-On

LEAD 1010 PLASMA Add-On is a great modification you can do for your LEAD 1010 to convert it into a metal cutting monster machine!

Build Author

OffAxis

Views

7903

Build Author

OffAxis

Views

7903

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

d0rk1e

Views

7884

Build Author

d0rk1e

Views

7884

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

Build Author

Brandon Satterfield

Views

7822

Build Author

Brandon Satterfield

Views

7822

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Build Author

Martin.Barfoed

Views

7330

Build Author

Martin.Barfoed

Views

7330

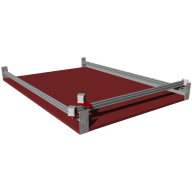

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Build Author

Stokrotka74

Views

7088

Build Author

Stokrotka74

Views

7088

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Fabio Orsi

Views

7027

Build Author

Fabio Orsi

Views

7027

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Build Author

patnap71

Views

7001

Build Author

patnap71

Views

7001

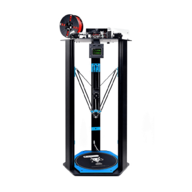

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

Bruno Rivard

Views

6964

Build Author

Bruno Rivard

Views

6964

OB Heavy duty Prusa i3 "Lunar Injection"

Hell Yeah

Build Author

Liam Dahler

Views

6633

Build Author

Liam Dahler

Views

6633

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Build Author

Terone Burgenheim

Views

6579

Build Author

Terone Burgenheim

Views

6579

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Build Author

TurfnSurf

Views

6299

Build Author

TurfnSurf

Views

6299

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

Luke Cunningham

Views

5980

Build Author

Luke Cunningham

Views

5980

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Kevr102

Views

5978

Build Author

Kevr102

Views

5978

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Build Author

Donald D. Parker

Views

5723

Build Author

Donald D. Parker

Views

5723

BABE - CanUSA Blue OX, bigger than the average OX

This is a basic description of my OX-like build of Babe, Paul Bunyan's Blue Ox. It is a work in progress. The idea has been germinating for about 4 years, with several twists and turns and false starts along the way.

Build Author

Ted Moyer

Views

5659

Build Author

Ted Moyer

Views

5659

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Build Author

3D Meister

Views

5658

Build Author

3D Meister

Views

5658

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Build Author

Sergei Starovoitov

Views

5647

Build Author

Sergei Starovoitov

Views

5647

Motorized mic stand

This system allows you to adjust the position of the microphone remotely

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

Craig Hollabaugh

Views

5039

Build Author

Craig Hollabaugh

Views

5039

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

RSch

Views

5025

Build Author

RSch

Views

5025

Scroll-saw Spiral Cutter

Attached to a scroll saw you can cut nested wooden spirals with this jig. Make two, three, four ... interlocking spirals that unwind/unscrew. Fascinating toys or art objects!

Build Author

James Evanko

Views

4997

Build Author

James Evanko

Views

4997

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Limine3D

Views

4731

Build Author

Limine3D

Views

4731

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

islahcnc

Views

4517

Build Author

islahcnc

Views

4517

islahcnc&design

I will post soon some more details.

Build Author

Quinnthouzand

Views

4181

Build Author

Quinnthouzand

Views

4181

Mustardo - The Mustard Bot

The goal for this bot is to lay down mustard on sausages and burger patties in a smooth and sexy way that looks good for the camera.

Build Author

Edgar Robles

Views

4159

Build Author

Edgar Robles

Views

4159

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Jones

Views

4089

Build Author

Jones

Views

4089

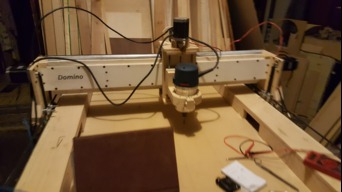

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

Build Author

hbtousa

Views

3384

Build Author

hbtousa

Views

3384

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

Neil Scott

Views

3383

Build Author

Neil Scott

Views

3383

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Router Box

This box is made from tough aluminum with plastic boards, helps hold WiFi Routers, Modems, or/ Ethernet Switches! The aluminum can resist the heat produced by these electronics, and the weight of the electronics, also being light itself. This box is the thing you need to hold your electronic devices!

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)