Build List

-

Active Filters:

m

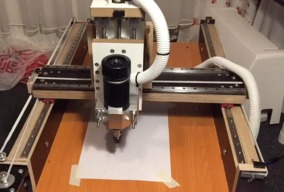

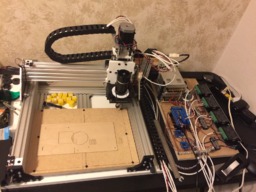

Small Slot Cutter

A build to cut .008 inch slots into JB Weld.

Build Author

joetemus

Views

6861

Build Author

joetemus

Views

6861

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

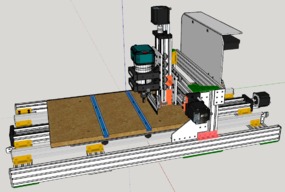

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Build Author

Craig Hollabaugh

Views

4910

Build Author

Craig Hollabaugh

Views

4910

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Vin1027

Views

7362

Build Author

Vin1027

Views

7362

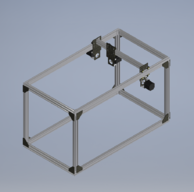

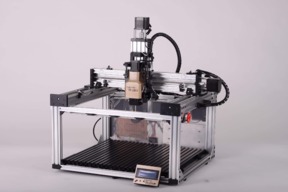

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Vegard Humlen

Views

5034

Build Author

Vegard Humlen

Views

5034

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

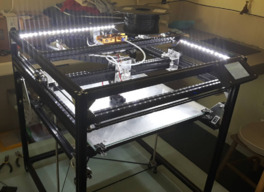

SMD Pick and place machine - Smoothieboard/OpenPnp

A dual head PNP machine that uses Openbuilds hardware, a Smoothieboard controller, dual camera vision, automatic/drag feeders, and OpenPnp.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Troy Proffitt

Views

29067

Build Author

Troy Proffitt

Views

29067

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

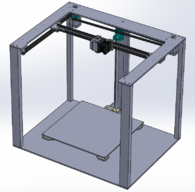

Build Author

CoreCube3D

Views

22078

Build Author

CoreCube3D

Views

22078

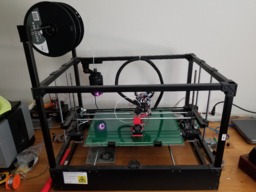

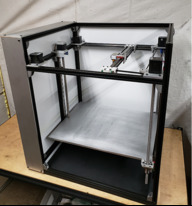

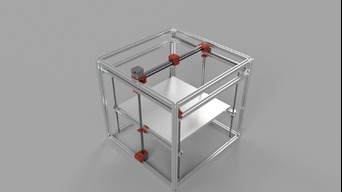

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

Build Author

Christian James

Views

10018

Build Author

Christian James

Views

10018

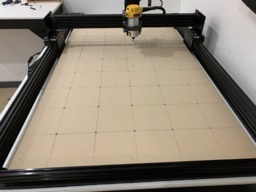

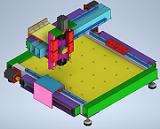

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Jay Almers

Views

8058

Build Author

Jay Almers

Views

8058

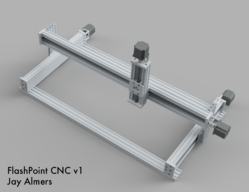

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Cortellini

Views

5609

Build Author

Cortellini

Views

5609

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Build Author

Doug Rowley

Views

4352

Build Author

Doug Rowley

Views

4352

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

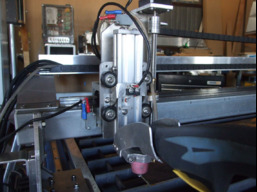

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Build Author

patnap71

Views

6922

Build Author

patnap71

Views

6922

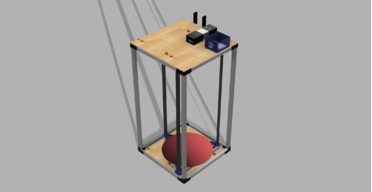

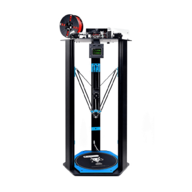

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

Stan Howe

Views

3360

Build Author

Stan Howe

Views

3360

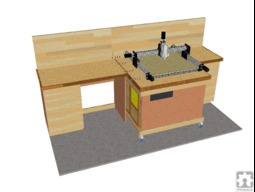

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

holographic

Views

7944

Build Author

holographic

Views

7944

Laser DIY

How i construct and create my DIY Co2 Laser cutter and engraving mashine. details will follow

Build Author

Hidro669

Views

3786

Build Author

Hidro669

Views

3786

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Indoor Drumline Props

Triangular Towers

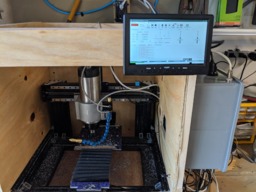

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Build Author

HuguesP

Views

7559

Build Author

HuguesP

Views

7559

Peristaltic pumps, Automatic Cocktail mixer

This is an automatic cocktail mixer made with 8 small peristaltic pumps. this is driven with the touch screen or over wifi. the controller used is a raspberry pi with a Apache webserver

My build

I am satisfied with my build and next one will be even better.

Build Author

Cortellini

Views

4539

Build Author

Cortellini

Views

4539

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

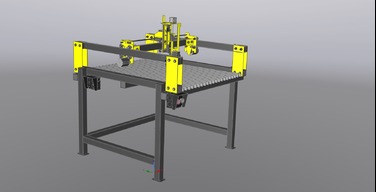

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

KronBjorn

Views

4480

Build Author

KronBjorn

Views

4480

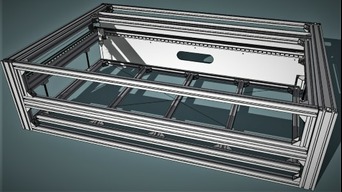

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Vacuum laser table

Large 10’x6’ vacuum table made from steel tubing and 1/4 inch steel plate

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Build Author

James Evanko

Views

7323

Build Author

James Evanko

Views

7323

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

75x75

Simple cnc with 5mm steel plates.

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

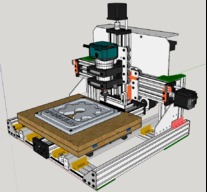

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

Build Author

Sir Bagels

Views

3129

Build Author

Sir Bagels

Views

3129

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Build Author

mjenkins5720

Views

2958

Build Author

mjenkins5720

Views

2958

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

x_y_module laser engraver

low cost 2 axis cnc laser, really portable and easily expandable

Build Author

Marco964

Views

9039

Build Author

Marco964

Views

9039

Lead CNC 1510 modified

This is an Openbuilds LEAD 1510, modified to supports a liquid cooled 1.5Kw spindle. The movements are made with lead screw on all three axes.

Add more V-Slot to my Makerfarm 10" Prusa i3v

Upgrade my 5 year old Makerfarm printer to use more V-Slot

Build Author

Mark Carew

Views

66594

Build Author

Mark Carew

Views

66594

High Z Mod for Lead CNC

The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router.

Filament winder ( carbon fiber )

Carbon fiber filament winder

Sim Racing rig

Made with OpenBuilds 2020 and 2060 material/brackets/hardware. Simlabs wheel deck. Fanatec DD wheel base/wheel/pedals NRG seat Sim racing studio wind simulators Few 3D printed brackets/caps/cable holds

Build Author

tmadrms

Views

7746

Build Author

tmadrms

Views

7746

C-Beam Mods

C-beam machine mods.

Build Author

Bruce Walker

Views

7132

Build Author

Bruce Walker

Views

7132

BD's Burn Box - ACRO Laser Engraver System

Two plus years in the making, I finally have a working ACRO 510 laser engraver system complete with enclosure and air filtration.

Build Author

Joe F

Views

8529

Build Author

Joe F

Views

8529

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

Sonny Lowe

Views

6957

Build Author

Sonny Lowe

Views

6957

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

Build Author

Darren Dickson

Views

4481

Build Author

Darren Dickson

Views

4481

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

David Florian

Views

11657

Build Author

David Florian

Views

11657

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Build Author

DaleShaw

Views

4489

Build Author

DaleShaw

Views

4489

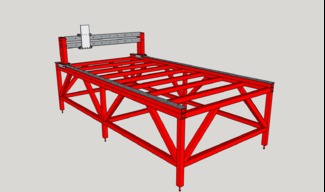

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

1250x1000 Build

A new design of my based on a couple different machines I have seen both on openbuilds and youtube. In the end will have a and X/Y workspace of 1250mm x 1000mm and a Z axis range of about 200mm.

Core XY Beast

Super solid core xy build inspired by the e3d tool changer

Build Author

mathom713

Views

9638

Build Author

mathom713

Views

9638

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Build Author

jeff johnson

Views

5774

Build Author

jeff johnson

Views

5774

workbee 1510

Getting more height out of the !510

Build Author

Forestbird Originals

Views

5502

Build Author

Forestbird Originals

Views

5502

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Build Author

Corey Corbin

Views

5110

Build Author

Corey Corbin

Views

5110

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

Build Author

txcomp

Views

6875

Build Author

txcomp

Views

6875

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

Daniel Stewart

Views

2049

Build Author

Daniel Stewart

Views

2049

Ultra sun cutter

A sun cutter only using mirror and glass balls with x and y table movement

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

Massive Hotwire Foam Cutter

CNC Hot Wire Foam Cutter. Lathe, Turntable and 4 axis Cutter. Can cut XPS and EPS.

Bored in the garage enclosure build

2 days to build Up and running some EMI issues but I think I have them resolved Big shoutout to the community

Build Author

Braden Masse

Views

3663

Build Author

Braden Masse

Views

3663

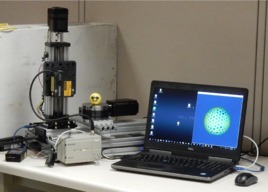

Microwave Filter Tuner

The Microwave Filter Tuner (MFT) combined with the University of Regina’s tuning algorithm automatically tunes microwave filters by using a custom CNC machine with a computer vision system for identifying, mapping, and tuning each filter element, providing improved consistency, flexibility, and accuracy compared to traditional methods. The MFT is low cost and is capable of tuning multiple filter configurations with minimal preparation.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Build Author

Tristen Poliseno

Views

4311

Build Author

Tristen Poliseno

Views

4311

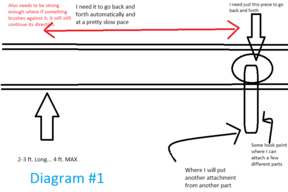

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

Build Author

shanehooper

Views

15924

Build Author

shanehooper

Views

15924

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Quinnthouzand

Views

4078

Build Author

Quinnthouzand

Views

4078

Mustardo - The Mustard Bot

The goal for this bot is to lay down mustard on sausages and burger patties in a smooth and sexy way that looks good for the camera.

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Build Author

Leboeuf

Views

5031

Build Author

Leboeuf

Views

5031

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Build Author

Yosmany325

Views

2440

Build Author

Yosmany325

Views

2440

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Build Author

Damian V-SLOT Poland

Views

16159

Build Author

Damian V-SLOT Poland

Views

16159

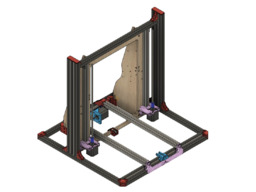

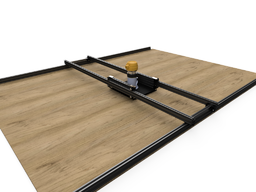

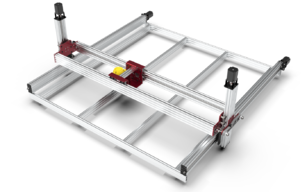

DIY Slab Flattening Mill

V-SLOT profiles and OpenBuilds accessories give us many possibilities. We decided to build a manual ROUTER SLED using only components of the OpenBuilds system. The design is simple to build, construction takes little time, and the frame is easy to transport.

Build Author

Srđan Marković

Views

4039

Build Author

Srđan Marković

Views

4039

Second machine

Machine with 12,5Nm closed loop steppers or servo steppers

Build Author

OpenBuilds

Views

17307

Build Author

OpenBuilds

Views

17307

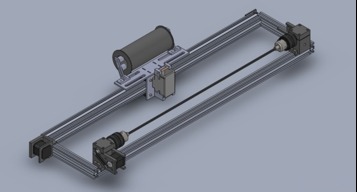

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

Crazzy French Dude

Views

5423

Build Author

Crazzy French Dude

Views

5423

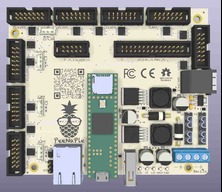

PeeNaPle_V1.4b

PeeNaPle_V1.4b is a BoB controller board for 3D Printers, CnC and cartesian machine, using the latest Teensy_4.1

Build Author

Yanou Fishel

Views

11412

Build Author

Yanou Fishel

Views

11412

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

CNC Plasma Table 006

Inexpensive plasma table. Accurate, fast, and low maintenance.

Build Author

OpenBuilds

Views

27064

Build Author

OpenBuilds

Views

27064

OpenBuilds Table Series

The OpenBuilds Table Series offers a modular table structure that grows with your needs.

Build Author

Colin Russon

Views

3943

Build Author

Colin Russon

Views

3943

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

Jose Alezandre

Views

2217

Build Author

Jose Alezandre

Views

2217

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

Phlat Printer 3 meets Open Builds

I will go over the attachments for the PP3 Z axis. soon. Before any thing else .You need to know the first PP3 ,used SKP 7 and Mach 3. Later on they used CNC USB.

Build Author

OpenBuilds

Views

11908

Build Author

OpenBuilds

Views

11908

Swing Arm

Simple Swing Arm Build for the Modular Table Series. Create a simple vacuum swing arm that swings over your machine keeping your vacuum hose and router cord, etc. up and out of the way

Build Author

OpenBuilds

Views

4736

Build Author

OpenBuilds

Views

4736

Interface magnetic mount

A simple build that helps you to mount the OpenBuilds Interface to the front of your machine.

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Build Author

Frank Gore

Views

9876

Build Author

Frank Gore

Views

9876

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

MOVABLE ART TO SCREEN WALL-MOUNTED TV

This project produced a movable framed canvas to cover a wall-mounted flat-screen TV when not being viewed, which at the touch of of a switch moves down below the TV and sound bar. The same switch is used afterwards to return the artwork up to cover the TV again. Photo shows mechanism without the canvas frame. See other photos.

Build Author

Sergei Starovoitov

Views

5497

Build Author

Sergei Starovoitov

Views

5497

Motorized mic stand

This system allows you to adjust the position of the microphone remotely

Build Author

2SIsurf

Views

6604

Build Author

2SIsurf

Views

6604

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

GIGAWATT 2.1 LASER CUTTER

Progetto di un laser CO2 da 50w Autocostruito, con scheda di controllo MKS Sbase v.1.3 Firmware Smoothieware versione CNC Struttura realizzata con profili T-slot 20x20 e 20x40

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

DRO

Belt drive linear scale for Mill and Lathe

HYDRA multi tool CNC , based on ACRO

modifying ACRO