Build List

-

Active Filters:

k

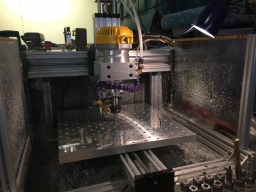

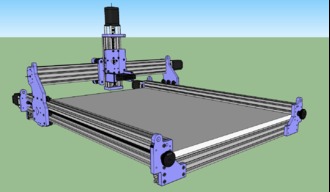

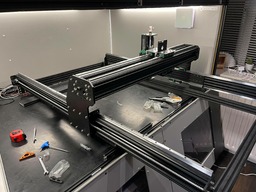

Workbee with Duet controller

Workbee 1010 with Duet controller from Ooznest

Build Author

James Evanko

Views

7355

Build Author

James Evanko

Views

7355

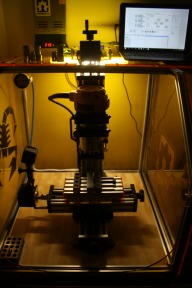

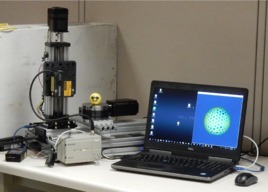

Laser Displacement Golf Ball Scanner

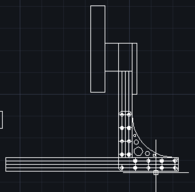

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

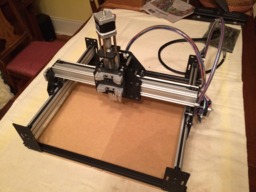

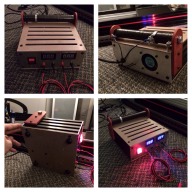

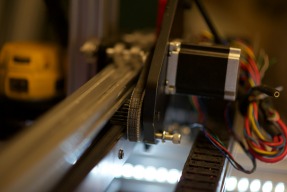

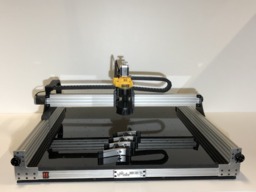

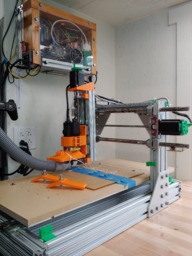

Minimalist Laser Platform

Minimalist laser platform built with Makerlink connectors and modified Nema 17 stepper mounts used as gantry plates.

Build Author

ajdubs

Views

5635

Build Author

ajdubs

Views

5635

A custom arcade

This is an arcade "cabinet" of sorts built almost entirely from OpenBuilds extrusions. Save for a few 3d printed parts, the electrical components, the acrylic panels, and the monitor mount, every component was purchased from the OpenBuilds part store.

Build Author

SlyClockWerkz

Views

16955

Build Author

SlyClockWerkz

Views

16955

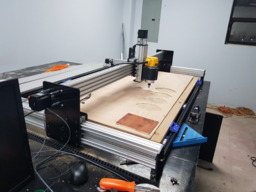

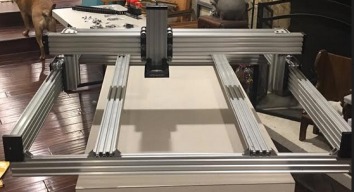

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

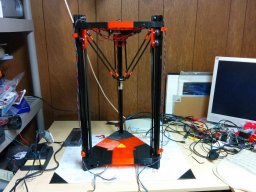

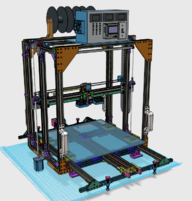

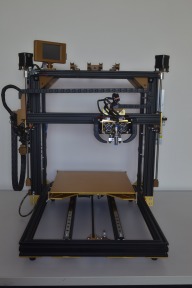

OKMI 3d Printer

OKMI 3d Printer based on CoreXY

Build Author

ymilord

Views

22327

Build Author

ymilord

Views

22327

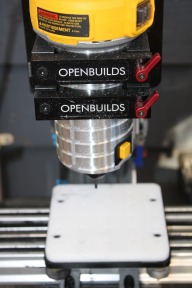

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

Rob Taylor

Views

20461

Build Author

Rob Taylor

Views

20461

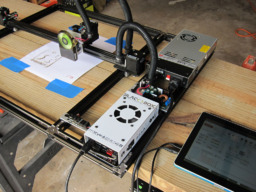

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

ymilord

Views

12761

Build Author

ymilord

Views

12761

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Build Author

Apothus

Views

22550

Build Author

Apothus

Views

22550

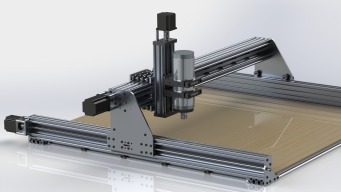

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

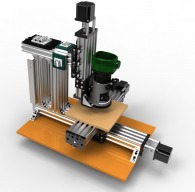

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Build Author

Superslinky

Views

10346

Build Author

Superslinky

Views

10346

K40 Laser Build (Major Changes)

Major K40 Laser Mod

Build Author

CharlieShimota

Views

16274

Build Author

CharlieShimota

Views

16274

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

C_Beam Hammerhead 5x

setup for learning 5x

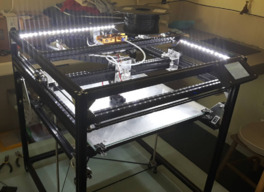

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

crypt-tek

Views

10086

Build Author

crypt-tek

Views

10086

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Build Author

2SIsurf

Views

6647

Build Author

2SIsurf

Views

6647

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

Small Red OX

A small router for thin plate stock

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

Build Author

Yoshiya Arii

Views

42146

Build Author

Yoshiya Arii

Views

42146

V-Slot Laser cutter and engraver

The Smart Laser Mini is an open source such as use Raspberry pi. Easy to assemble type of desktop laser cutter and engraver. Also we used V-slot

Build Author

Sonny Lowe

Views

7036

Build Author

Sonny Lowe

Views

7036

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

pek

Views

6530

Build Author

pek

Views

6530

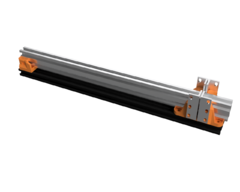

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

Build Author

Rob Mahan

Views

13893

Build Author

Rob Mahan

Views

13893

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

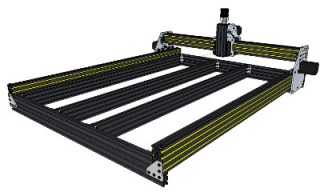

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Glenn Weston

Views

11518

Build Author

Glenn Weston

Views

11518

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Build Author

CoreCube3D

Views

22187

Build Author

CoreCube3D

Views

22187

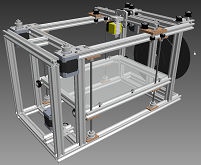

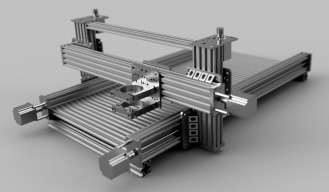

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

x_y_module laser engraver

low cost 2 axis cnc laser, really portable and easily expandable

Build Author

Jason Moore

Views

13194

Build Author

Jason Moore

Views

13194

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

The Almost Perfect 3 Way Mitre (with MakerLinks)

A quick and easy way to make a 3-way mitered corner using MakerLinks

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

GDanger117

Views

12435

Build Author

GDanger117

Views

12435

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Keith Davis

Views

5482

Build Author

Keith Davis

Views

5482

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

Black Box/ Power supply brackets

This items are so cool that they need to be together, so I decided to create brackets that connect both pieces together

Build Author

OpenBuilds

Views

29830

Build Author

OpenBuilds

Views

29830

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

CNCGear

Views

10737

Build Author

CNCGear

Views

10737

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Build Author

Mark Carew

Views

132814

Build Author

Mark Carew

Views

132814

V-Slot® NEMA 17 Linear Actuator (Belt Driven)

Quick and Simple V-Slot Gantry System. This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts. You can mount this system an many ways so be sure to download the example models.

Camera slider for stacking focus

This is just a small project to get use to the OpenBuild products.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

John J Talavera

Views

18751

Build Author

John J Talavera

Views

18751

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

DIY anodizing power supply

How to make your own anodizing power supply on a budget

Build Author

Teflon4

Views

15981

Build Author

Teflon4

Views

15981

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

Build Author

UltiBots

Views

10599

Build Author

UltiBots

Views

10599

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

Build Author

crystaldragon141

Views

6604

Build Author

crystaldragon141

Views

6604

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Build Author

megashub

Views

24396

Build Author

megashub

Views

24396

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Carl Siren

Views

7696

Build Author

Carl Siren

Views

7696

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Calotype

Views

3628

Build Author

Calotype

Views

3628

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

Bob Darrow

Views

10214

Build Author

Bob Darrow

Views

10214

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Build Author

pedrofernandez

Views

10071

Build Author

pedrofernandez

Views

10071

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

Build Author

Vunnie

Views

6832

Build Author

Vunnie

Views

6832

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Build Author

Kenneth Witthuhn

Views

8549

Build Author

Kenneth Witthuhn

Views

8549

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Build Author

boutrous

Views

9164

Build Author

boutrous

Views

9164

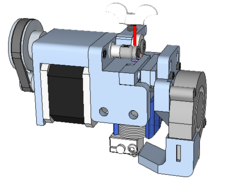

Laser Rotary Attachment

Build Summary updated after parts list completed

Richrap 3DR Mashup

A work in progress. working to refine the print head/carriage to integrate a bed level probe directly into the print head.

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Build Author

Limine3D

Views

21866

Build Author

Limine3D

Views

21866

M3Delta

Delta printer designed in sketchup and includes an adjustable bed.

Build Author

evildean

Views

8937

Build Author

evildean

Views

8937

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Build Author

Gerrald

Views

6415

Build Author

Gerrald

Views

6415

Pong CNC

This build is to show what's possible as well with openBuilds! I use a single ArduinoMega and 5 separate stepper drivers (A4988). The LEDs are all NeoPixels. Collision 'detection' is all done within the code, so the endstops are only sensors I use in this build. I'm a self-employed video-artist and this is my first installation which just needs power and it runs (where I'm quite proud of). Normally my interactive installations take a long setup time, so this installation is a relief :)

Archivist Quill Book Scanner

This is a book scanner built out of aluminum extrusion. It is designed to get high quality scans without harming the book. It is not automated. You still have to turn the pages yourself.

Build Author

griso

Views

9313

Build Author

griso

Views

9313

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

Build Author

Tucstrlly

Views

9121

Build Author

Tucstrlly

Views

9121

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

Kyo

Views

10165

Build Author

Kyo

Views

10165

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

Dave Pyatt

Views

4553

Build Author

Dave Pyatt

Views

4553

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

MattR

Views

20634

Build Author

MattR

Views

20634

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

ChrisViral

Views

7197

Build Author

ChrisViral

Views

7197

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Build Author

Ariel Yahni

Views

6688

Build Author

Ariel Yahni

Views

6688

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

Build Author

Cortellini

Views

4567

Build Author

Cortellini

Views

4567

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

Build Author

Joe F

Views

8571

Build Author

Joe F

Views

8571

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Vslot Kossel

Base is a Delta Kossel Printer modified to be build with openbuild parts like vslot 20x40 , pulley .... It inclued the latest modification for auto level : FSR

Build Author

Nugz

Views

13552

Build Author

Nugz

Views

13552

Angus : A Slightly "Beefier" OX

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12606

Build Author

AndersFaust

Views

12606

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

Kyo

Views

12603

Build Author

Kyo

Views

12603

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

k nest

This Build Is Is Inspired By OOZ Nest CNC, But With Some Changes,

Build Author

JP Warnke

Views

12874

Build Author

JP Warnke

Views

12874

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Nicademus

Views

9629

Build Author

Nicademus

Views

9629

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

TurfnSurf

Views

7177

Build Author

TurfnSurf

Views

7177

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Build Author

Bikes and Beer

Views

4913

Build Author

Bikes and Beer

Views

4913

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Martin.Barfoed

Views

7188

Build Author

Martin.Barfoed

Views

7188

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

txcomp

Views

6907

Build Author

txcomp

Views

6907

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.