Build List

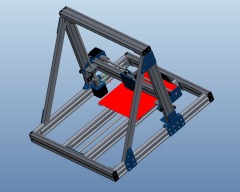

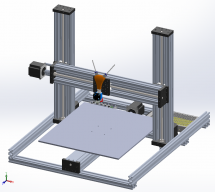

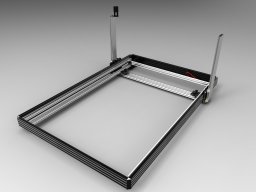

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

Build Author

Project Hopeless

Views

14484

Build Author

Project Hopeless

Views

14484

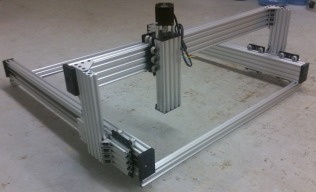

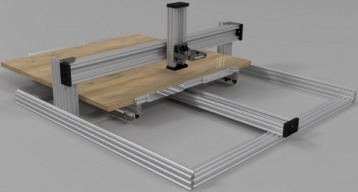

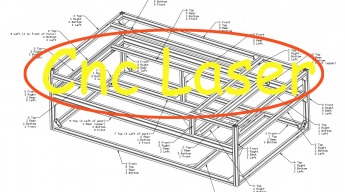

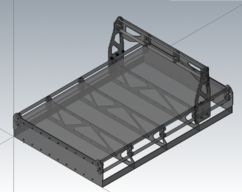

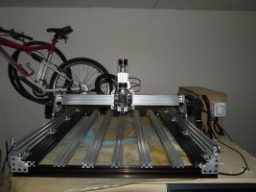

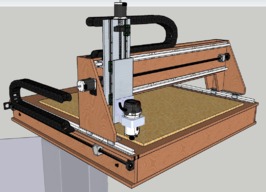

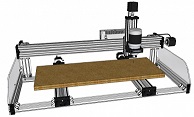

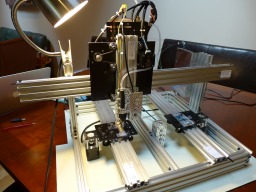

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

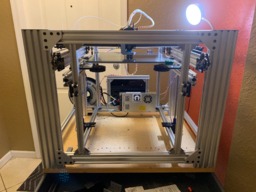

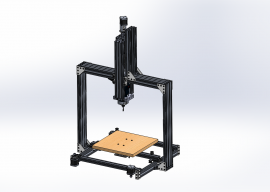

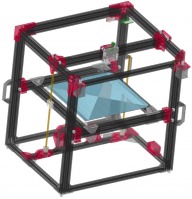

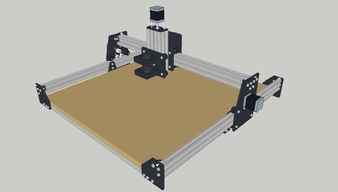

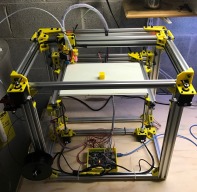

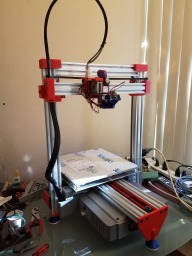

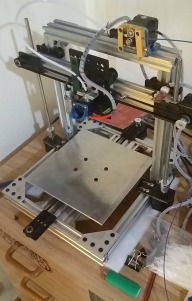

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

Build Author

Martin.Barfoed

Views

7106

Build Author

Martin.Barfoed

Views

7106

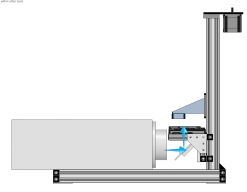

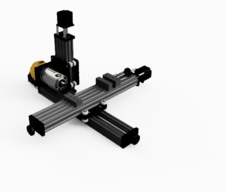

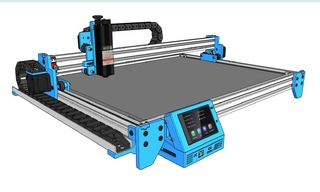

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

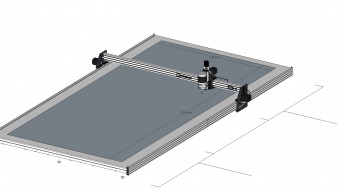

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

Build Author

Troy Joachim

Views

18485

Build Author

Troy Joachim

Views

18485

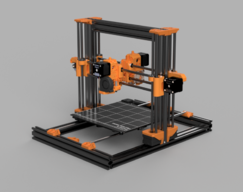

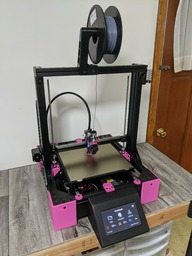

Prusa i3 Bear IDEX

Remix of the Prusa i3 Bear with added IDEX

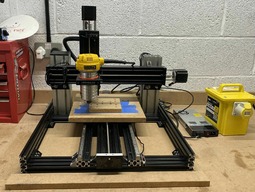

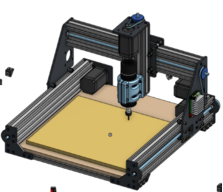

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Build Author

Yanou Fishel

Views

11398

Build Author

Yanou Fishel

Views

11398

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

Build Author

Quentin Karmark

Views

9462

Build Author

Quentin Karmark

Views

9462

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Custom 40W Laser Cutter

So this is my custom 40W build. I wanted to make another laser similar to the one I built but a lot smaller and an all in one system so that if I ever decide to do a farmers market or something similar, I wanted to be able to put the laser on the back of the car and drive to whatever location. I think it's going to work. It will be see-through with lights and screens eveywhere. The lights alone should attract people like flies. That's the plan anyway.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

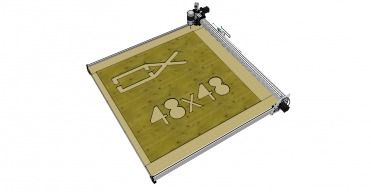

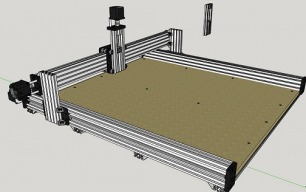

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

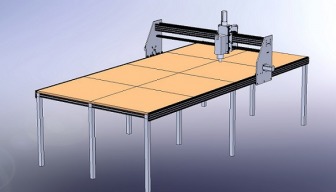

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

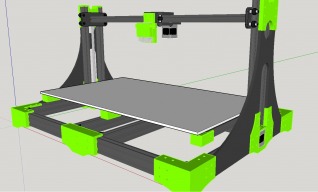

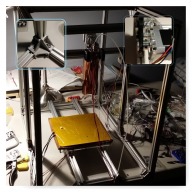

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

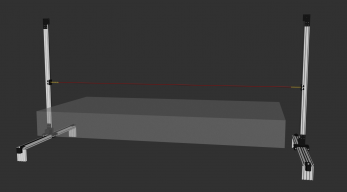

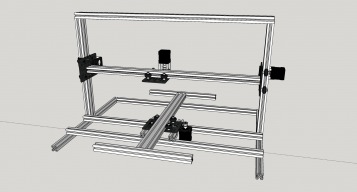

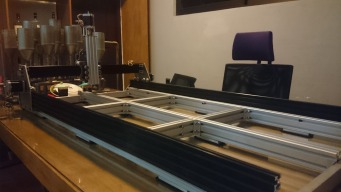

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

Build Author

rusirius

Views

16925

Build Author

rusirius

Views

16925

MultiBOT LRP

A CNC platform designed with swapable heads to do laser engraving/etching/cutting, routing and milling, as well as 3D printing.

Build Author

Kermareg

Views

17368

Build Author

Kermareg

Views

17368

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

Steve hope

Views

19226

Build Author

Steve hope

Views

19226

8x4 CNC build

Routy cnc upgrade.

Build Author

brw_racing

Views

16273

Build Author

brw_racing

Views

16273

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

motopreserve

Views

9102

Build Author

motopreserve

Views

9102

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

OX TWO in ONE

What I'm doing is pretty self explanatory. I've put a few pictures up

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

Build Author

Laurence Carroll

Views

10972

Build Author

Laurence Carroll

Views

10972

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Sam Dobbie

Views

7817

Build Author

Sam Dobbie

Views

7817

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

Build Author

Neptunes Guitars

Views

8531

Build Author

Neptunes Guitars

Views

8531

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

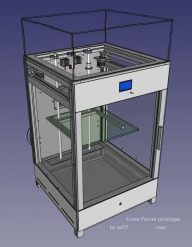

Tower Printer

Tower Printer H-Belt type printer Prototype

Build Author

UltiBots

Views

13662

Build Author

UltiBots

Views

13662

Metal MagBall Carriage

UltiBots LLC designs and packages DeltaBot 3D printers using quality components. Our kits are V-Slot based. Print results are impressive. The Metal MagBall Carriage was designed to be ridged, compact, and simple.

MakerSL MSL-6 DLP 3D Printer

This will be a DLP 3D Printer designed around an Openbuilds Frame and rail system. It will be a collaborated effort between myself and Ben Smith. We will be building two prototypes.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

C-Beam based modular Resin Printer

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Mini D-Bot

A smaller version of a standard D-bot. Smaller to fit better in my workable area and to fit my vision for the printer.

V-Slot Linear Actuator Bundle

v-slot linear actuator build.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

CNC Planning

Reusing parts to build a CNC - planning stage

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Build Author

spark2

Views

5700

Build Author

spark2

Views

5700

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Something a Tad different

Future CNC router kit design

Build Author

Axnfell

Views

3107

Build Author

Axnfell

Views

3107

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

jpjoshua

Views

13445

Build Author

jpjoshua

Views

13445

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Pick and place

Openbuilds Pick and Place using ideas from OpenPNP Frame work is from the Openbuilds Part store using 1000mm C beams and vslot 40x40 for support Surface is 3/4 " Particle board

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

C-CNC

Views

16254

Build Author

C-CNC

Views

16254

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

SMD Pick and place machine - Smoothieboard/OpenPnp

A dual head PNP machine that uses Openbuilds hardware, a Smoothieboard controller, dual camera vision, automatic/drag feeders, and OpenPnp.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

Build Author

John Pollman

Views

7399

Build Author

John Pollman

Views

7399

Wanhao Duplicator i3 Plus - Major rebuild.

Major rebuild of my Wanhao Duplicator i3 Plus.

Build Author

RV6APilot

Views

4243

Build Author

RV6APilot

Views

4243

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Build Author

Bruce Walker

Views

7122

Build Author

Bruce Walker

Views

7122

BD's Burn Box - ACRO Laser Engraver System

Two plus years in the making, I finally have a working ACRO 510 laser engraver system complete with enclosure and air filtration.

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Build Author

Stokrotka74

Views

6953

Build Author

Stokrotka74

Views

6953

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

Build Author

M1dn1ghtN1nj4

Views

10075

Build Author

M1dn1ghtN1nj4

Views

10075

The Beast

This is a heavily modified system based on the RatRig V-Cast. Lots of personal touches, and a LOT more to come!

Workbee with less irritations

My workbee build with some add ons

Black gear 1500X3000

My cnc update and rebuild.

ME - Laser CNC

Build of a small laser engraver using V-slot profiles and 3d printed parts

KillerBee 1515 customized

Killerbee 1515 with modifications.

7 Axis Camera Slider with Telescoping Vertical Lift

A six axis camera slider with a 7th LIFT axis added!

Y-1200 co2 laser

Y-1200 Build The Y-1200 has a cutting area of 1200 x 600mm and the main chassis has a external size of 1620 x 955 x 450mm. The recommended power output is 60-90W, this can also be increased with the use of an extension box. designed by furtherfabrication ROB CHESNEY FREELANCE INDUSTRIAL DESIGNER.

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

Build Author

EvanH

Views

4899

Build Author

EvanH

Views

4899

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

Build Author

Colin Russon

Views

8711

Build Author

Colin Russon

Views

8711

RoboFoamCutter

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

spunks.cam

Design of a multifunctional CNC machine.

Build Author

richthorn

Views

8267

Build Author

richthorn

Views

8267

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Build Author

DiggerJ

Views

8786

Build Author

DiggerJ

Views

8786

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

d0rk1e

Views

7783

Build Author

d0rk1e

Views

7783

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

Large Volume 3D Printer

. .

Build Author

Joey Selzler

Views

13560

Build Author

Joey Selzler

Views

13560

My JGro CNC becomes an OpenBuild Project

This is the story of my progression from the JGRO cnc router design to using the OpenBuild system. In the process I think I have learned some things about cnc routers and the accuracy required to make a good build.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Build Author

Darren Ditto

Views

10697

Build Author

Darren Ditto

Views

10697

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Custom OX Build

Inspired by the original OX by Mark Carew, this is my Custom OX. Many small changes, additions, and upgrades. Build is in progress and this post will be updated regularly with photos. Enjoy!

Build Author

JoeH

Views

7665

Build Author

JoeH

Views

7665

COTSPnP

The COTSPnP pick-and-place machine (PnP) is used to place surface-mount devices (SMDs) onto a printed circuit board and was designed and built exclusively from off-the-shelf (COTS) components, predominantly sourced from OpenBuilds and Actobotics. Its intended use is prototyping and not high rate, high volume production and is capable of precisely placing parts as small as 0402 capacitors and resistors but more importantly, can precisely place components with lead spacing as small a 0.4mm.

Build Author

ymilord

Views

19456

Build Author

ymilord

Views

19456

Small Portable PCB CNC Machine (CoreXY)

This is a small CNC mill/router specifically for manufacture PCBs. This is based on the corexy gantry setup. The plan is to have a small, light self-contained machine that can be used and easily but away when it's job is done.

Viking OX

My OX cnc upgrade.

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

Build Author

Keteland

Views

10714

Build Author

Keteland

Views

10714

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

francesco pollina

Views

7147

Build Author

francesco pollina

Views

7147

FFF 3D printer 2x2x2m

The 3D printer will be able to print 2x2x2m components and not just in PLA or ABS. It's not just a DIY printer but I'm trying to apply engineering formulas to make it. I'm going to apply the state of art for 3D printing and scannering existing.