Build List

-

Active Filters:

l

Build Author

Anthony Bolgar

Views

11968

Build Author

Anthony Bolgar

Views

11968

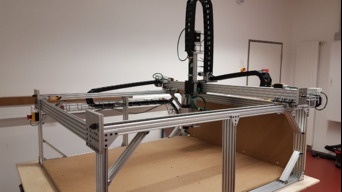

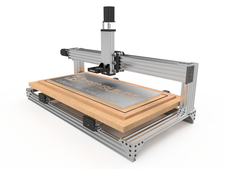

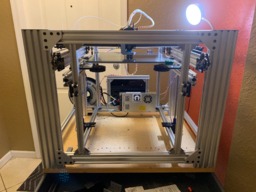

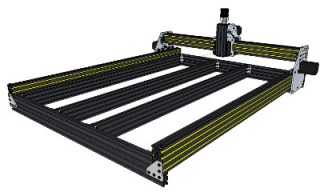

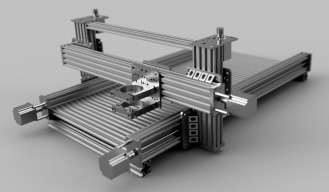

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

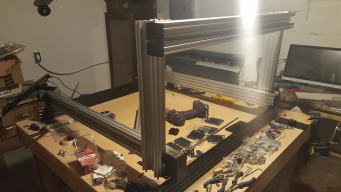

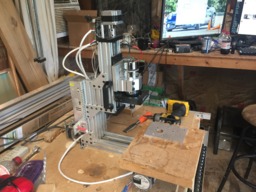

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Laser cutter

In the expo projects during the second year of engineering students. the project group who made this rapport made a laser cutter for the students of Fontys Hogeschool Engineering to use this machine for creating parts for their projects. The goal of Project Laser Cutter is to build a laser cutter, which is safe and can be used within the school. Also it has to be able to cut through 10 millimetres thick acrylic material or 10 millimetres thick plywood. This project will follow the V-model. This

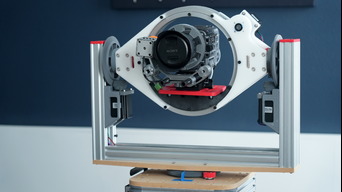

Archivist Quill Book Scanner

This is a book scanner built out of aluminum extrusion. It is designed to get high quality scans without harming the book. It is not automated. You still have to turn the pages yourself.

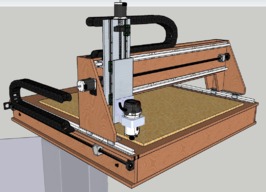

MiniMill

Building a small mill to match my 7x12 lathe.

Build Author

griso

Views

9206

Build Author

griso

Views

9206

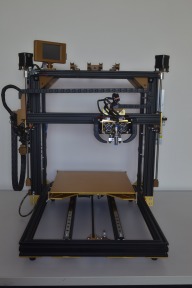

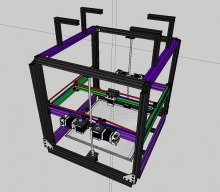

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Update for my 3D Printer - Big Size

I like combo machines, so I upgrade my 3D Printer with a Laser. It is a double head combination. The Laser is easy removable.

Build Author

mytechno3d

Views

6446

Build Author

mytechno3d

Views

6446

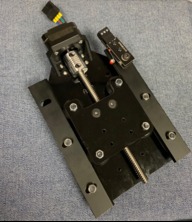

DSLR ( video ) motorized slider

In order to make some nice traveling video you need a slider .

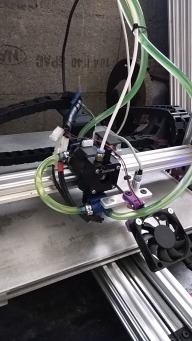

blackcat3d printer

in construction ! chassis vslot 80x20 & 20x20 & 60x80 (Z) home made plates with whells polycarbonate build volume environ, 750x300x200 2 ed3d v6 volcano nozzles 0.8mm & 0.6 + titan extrudeurs rumba bord + auto levelling ip camera home made heat bed aluminium 5mm + glass + heat air chamber 6 doors plexiglass......

Build Author

Krishnakumar

Views

8631

Build Author

Krishnakumar

Views

8631

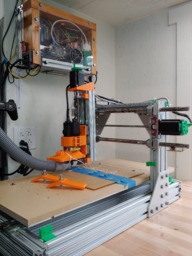

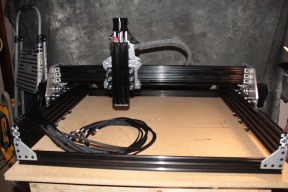

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

Jose A. Molina

Views

6913

Build Author

Jose A. Molina

Views

6913

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

Build Author

Savvas

Views

18614

Build Author

Savvas

Views

18614

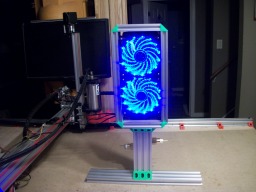

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Andrew Helsel

Views

12086

Build Author

Andrew Helsel

Views

12086

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

Tucstrlly

Views

9012

Build Author

Tucstrlly

Views

9012

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

Kyo

Views

10010

Build Author

Kyo

Views

10010

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

patdee

Views

5057

Build Author

patdee

Views

5057

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Build Author

MattR

Views

19938

Build Author

MattR

Views

19938

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

Build Author

ChrisViral

Views

7103

Build Author

ChrisViral

Views

7103

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Build Author

thinman

Views

8730

Build Author

thinman

Views

8730

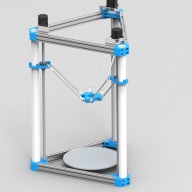

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

Build Author

Ariel Yahni

Views

6525

Build Author

Ariel Yahni

Views

6525

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

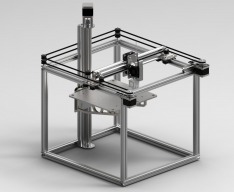

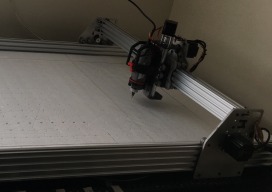

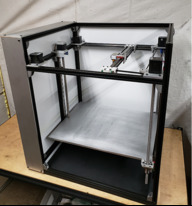

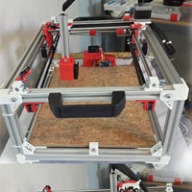

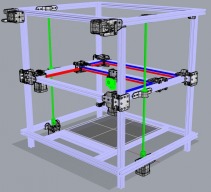

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

Build Author

Cortellini

Views

4462

Build Author

Cortellini

Views

4462

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

Build Author

rcKeith

Views

8459

Build Author

rcKeith

Views

8459

USB Hot Wire CNC Foam Cutter

Build a Hot Wire CNC Foam Cutter with inexpensive 3d printer electronics.

Rotary Axis for Laser Engraver/Cutter

This is a fully adjustable, low profile rotary axis for your Laser Cutter. Many OpenBuilds components are used, plus a handful of 3D printed parts.

Build Author

Joe F

Views

8406

Build Author

Joe F

Views

8406

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

David Florian

Views

11473

Build Author

David Florian

Views

11473

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

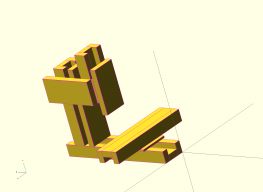

Z Axis for ACRO

Created a small Z axis for the ACRO motion system. I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. Also wanted to be able to vary the height for multiple cutting passes on some materials. Try to stick to a similar aesthetic as the original ACRO system and plates.

Massive Hotwire Foam Cutter

CNC Hot Wire Foam Cutter. Lathe, Turntable and 4 axis Cutter. Can cut XPS and EPS.

Build Author

Alexander Leiser

Views

21228

Build Author

Alexander Leiser

Views

21228

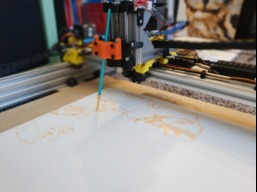

Paintbot painting cnc

Custom painting machine in designed and wrote the software for. Paintings are with acrylic color on canvas

Bored in the garage enclosure build

2 days to build Up and running some EMI issues but I think I have them resolved Big shoutout to the community

Build Author

OpenBuilds

Views

6657

Build Author

OpenBuilds

Views

6657

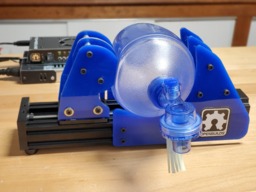

V-Slot Ventilator

The idea is to make a simple effective ventilator, studying the concept of using a simple push process with and actuator.

Build Author

shanehooper

Views

15683

Build Author

shanehooper

Views

15683

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Damian V-SLOT Poland

Views

16005

Build Author

Damian V-SLOT Poland

Views

16005

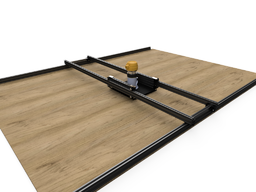

DIY Slab Flattening Mill

V-SLOT profiles and OpenBuilds accessories give us many possibilities. We decided to build a manual ROUTER SLED using only components of the OpenBuilds system. The design is simple to build, construction takes little time, and the frame is easy to transport.

(Smaug) 100w 1500x1000mm CNC Laser

Laser CNC made with mostly Openbuilds and amazon sourced components. Lots of 3d printed components as well. The main purpose is to cut EVA foam.

6 Axis Motion Control Camera Rig (PAN, TILT, ROLL, SLIDE, FOCUS, ZOOM)

6 axis rig based on OpenBuild C-Beam and ESP32 MCU, WiFi controlled with custom app.

LEAD 710 with High Z mod

Overview of a 700mm x 1000mm machine based on the LEAD design and with the High Z mod from the start. Will have a parts list you can use to build yourself if you like the formfactor

Build Author

OpenBuilds

Views

5769

Build Author

OpenBuilds

Views

5769

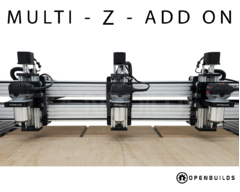

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Needle cutter for foamplates

Cutting Depron foam panels by an oscillating needle

Build Author

Keith Davis

Views

19068

Build Author

Keith Davis

Views

19068

BldrBot S2

A Prusa i3 design running on Open Build's mini V wheels

Vslot Kossel

Base is a Delta Kossel Printer modified to be build with openbuild parts like vslot 20x40 , pulley .... It inclued the latest modification for auto level : FSR

Long Ox with drop in table

This build is a modified Ox build. The long rails are 1000mm. My build includes a solid clamping table.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

Build Author

Rural

Views

25932

Build Author

Rural

Views

25932

OS OX

Mechanically, a scaled up OX build (1500x1500). Electronically, GRBL on an Arduino and a gShield. From a software perspective, the focus is on useable open source software tool chains.

Nebraska 1246 x 1184

This is my first attempt at a CNC anything build

OX Build

Standard OX Build

Build Author

Nugz

Views

13466

Build Author

Nugz

Views

13466

Angus : A Slightly "Beefier" OX

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.

Build Author

winand

Views

16984

Build Author

winand

Views

16984

YAOP (Yet Another Openbuilds Printer)

Yet Another Openbuilds Printer, my version :-P

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12483

Build Author

AndersFaust

Views

12483

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

andrew Adsit

Views

13958

Build Author

andrew Adsit

Views

13958

OX Cable Management, Electronics Case, E-Stops

750mm x 750mm OX build, xPro V2 controller, 400W Spindle with PWM controller.

Delta 3d Printer

I am going to use this as a build log for my delta 3d printer build. I have access to a MakerBOT to print some of the parts. I am still finishing up a few of the design elements but the idea is to have a rigid unit to eliminate deflection in components and maintain accuracy.

Build Author

TomH

Views

16292

Build Author

TomH

Views

16292

H-Bot CoreXY Cube with Fixed Build Plate

Use of V-Slot for frame and rails with option to use identical 500mm uncut lengths: 8 * 20x60 x 500mm 8 * 20x40 x 500mm 7 * 20x20 x 500mm (2 cut into four identical 125mm pieces for filament holders) Use of uncut 500mm rails obtained through use of 12 joining plates for use as spacers. Alternate approach is to trim two 20x40 and 1 20x20 rail by 6-8mm each. Build volume ~400mm cubed (with dual extruders). Use of only openbuilds components! Currently in design phase...

Build Author

Kyo

Views

12494

Build Author

Kyo

Views

12494

V-Slot Cutting System

A System of 3d printed parts to use along with your projects aluminum extrusion to cut your pieces of v-slot to length manually.

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

Build Author

Robert Bailey

Views

29336

Build Author

Robert Bailey

Views

29336

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

zelos

Views

19179

Build Author

zelos

Views

19179

ZelosLaser Engraver/Cutter 2.0 : Sturdy & Versatile

Zelos Laser Cutter Version 2.0 GRBL Shield with Nema 17 motors. 2 Watt laser for cutting and fine grayscale pictures built very sturdy and modular

Build Author

Steven Sampson

Views

10884

Build Author

Steven Sampson

Views

10884

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

JCPhlux

Views

26422

Build Author

JCPhlux

Views

26422

Tesseract

Large Core XY 3d Printer W/fixed build plate

Build Author

Dave420

Views

14586

Build Author

Dave420

Views

14586

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

Build Author

Rwetzler

Views

9303

Build Author

Rwetzler

Views

9303

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

TesseractXY (MendelMax 1.5 version)

History about making 3d printer.

Spindle cooling setup

Cooling system for water cooled spindle.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Build Author

Venturebit

Views

13638

Build Author

Venturebit

Views

13638

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

Build Author

JP Warnke

Views

12755

Build Author

JP Warnke

Views

12755

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Huub65

Views

9190

Build Author

Huub65

Views

9190

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Build Author

Beam

Views

11477

Build Author

Beam

Views

11477

DIY Flywheel Camera Slider

My take on a non affordable slider.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Build Author

Nicademus

Views

9483

Build Author

Nicademus

Views

9483

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

TurfnSurf

Views

7076

Build Author

TurfnSurf

Views

7076

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Big CNC plasma cutter

more later

Build Author

Kevr102

Views

5763

Build Author

Kevr102

Views

5763

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

JerwanDavis

Views

6037

Build Author

JerwanDavis

Views

6037

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

James Evanko

Views

4051

Build Author

James Evanko

Views

4051

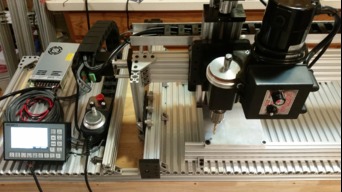

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Build Author

Bikes and Beer

Views

4801

Build Author

Bikes and Beer

Views

4801

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Jacob Lotter

Views

5917

Build Author

Jacob Lotter

Views

5917

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

Build Author

Project Hopeless

Views

14367

Build Author

Project Hopeless

Views

14367

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

Build Author

mathom713

Views

9583

Build Author

mathom713

Views

9583

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

Build Author

Martin.Barfoed

Views

6976

Build Author

Martin.Barfoed

Views

6976

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

txcomp

Views

6785

Build Author

txcomp

Views

6785

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)