Build List

Build Author

Matt Barile

Views

7539

Build Author

Matt Barile

Views

7539

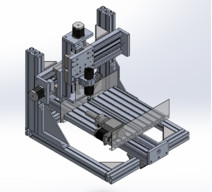

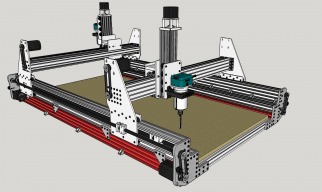

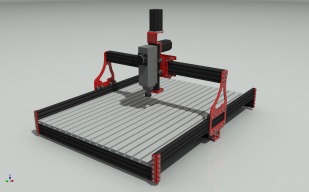

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

OBlathe

A simple wood turning lathe.

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

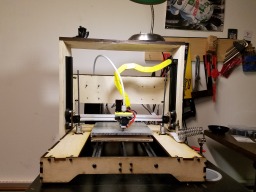

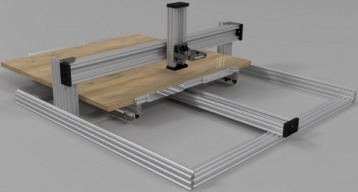

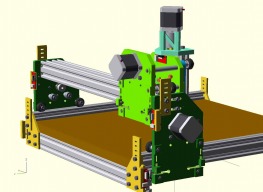

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

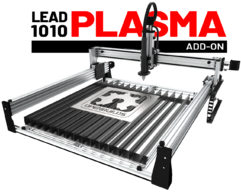

LEAD 1010 PLASMA Add-On

LEAD 1010 PLASMA Add-On is a great modification you can do for your LEAD 1010 to convert it into a metal cutting monster machine!

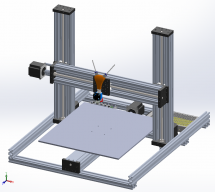

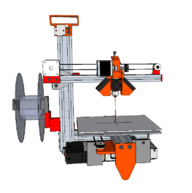

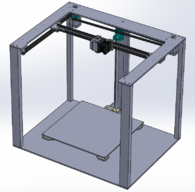

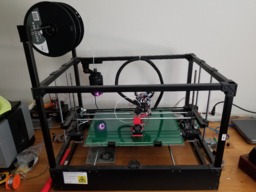

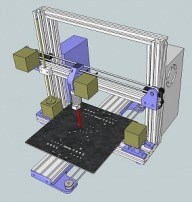

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

Build Author

Shaun Weitzel

Views

7522

Build Author

Shaun Weitzel

Views

7522

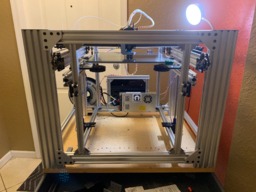

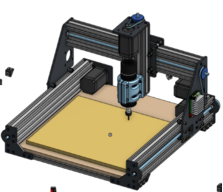

OpenBuilds Lead 1515

First build of a Lead 1515!

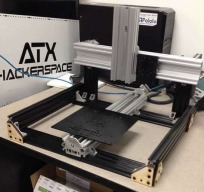

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

My Little OX

This build has been an educational experience. Software and hardware alike.

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

Build Author

Peter Van Der Walt

Views

7470

Build Author

Peter Van Der Walt

Views

7470

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

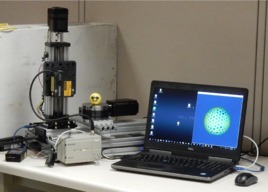

Touchsensor assembly machine

This is a handy machine to assemble touch sensors into display frame.

Core XY Beast

Super solid core xy build inspired by the e3d tool changer

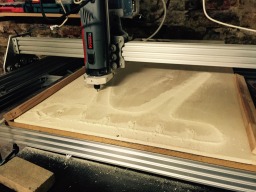

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

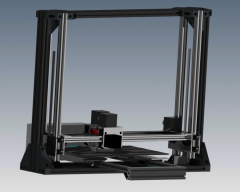

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

Josh Mascote

Views

7431

Build Author

Josh Mascote

Views

7431

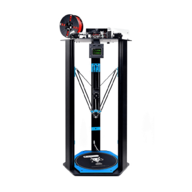

Z3D Delta Printer

Berrybot inspired delta 3d printer with a few other tweaks and modifications.

Brokkr CNC 2.0

1M C-beam xy variant

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Build Author

John Pollman

Views

7406

Build Author

John Pollman

Views

7406

Wanhao Duplicator i3 Plus - Major rebuild.

Major rebuild of my Wanhao Duplicator i3 Plus.

Rigidbot Big with glass bed

Started with a Rigidbot Big Added a single flat glass bed Used a Smoothieboard clone driving DRV8825

Build Author

mirage335

Views

7387

Build Author

mirage335

Views

7387

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Build Author

Tom Dirriwachter

Views

7382

Build Author

Tom Dirriwachter

Views

7382

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Parthenon

Custom build, after building the prusa i3 and upgrading to i3v, I wanted to build something more sturdy that can print fast and more accurate. Model is built in Fusion 360

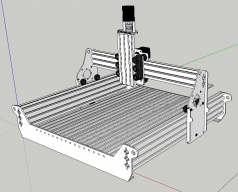

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Build Author

Vin1027

Views

7363

Build Author

Vin1027

Views

7363

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

evgeny156

Views

7350

Build Author

evgeny156

Views

7350

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

James Evanko

Views

7324

Build Author

James Evanko

Views

7324

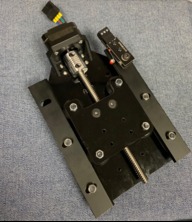

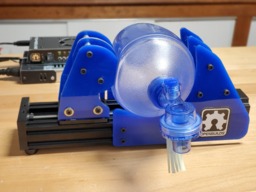

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

Jacob Christiansen

Views

7302

Build Author

Jacob Christiansen

Views

7302

ACRO 1010 with custom Z axis

This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting.

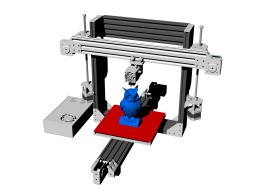

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

k nest

This Build Is Is Inspired By OOZ Nest CNC, But With Some Changes,

Tweakie's De-Mag.

A little project for a rainy day which some, like me, may find useful.

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

OneUpSolid

This is the adult version of the QU-BD juvenile known as their OneUp. It not only uses extrusion framing instead of press board MDF, it is a full sized 8x8 build area w/ABS-Nylon capability. Only the OneUp's single Z axis driver concept is similar. I'm tempted to call it OneUpAdult for marketing.

5'x10' CNC Plasma/Mill Table

Plasma Mill CNC

Build Author

Jonathon Duerig

Views

7222

Build Author

Jonathon Duerig

Views

7222

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

ChrisViral

Views

7182

Build Author

ChrisViral

Views

7182

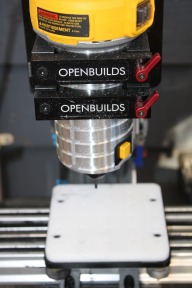

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

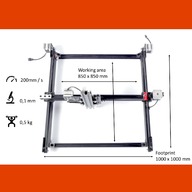

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

TurfnSurf

Views

7159

Build Author

TurfnSurf

Views

7159

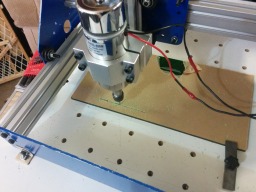

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

francesco pollina

Views

7157

Build Author

francesco pollina

Views

7157

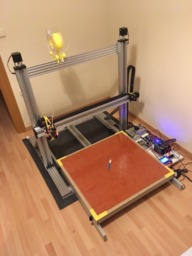

FFF 3D printer 2x2x2m

The 3D printer will be able to print 2x2x2m components and not just in PLA or ABS. It's not just a DIY printer but I'm trying to apply engineering formulas to make it. I'm going to apply the state of art for 3D printing and scannering existing.

CNC MILLING ROUTER

CNC MILLING ROUTER

Build Author

openhardwarecoza

Views

7141

Build Author

openhardwarecoza

Views

7141

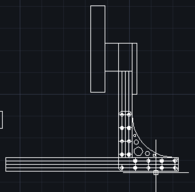

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

Small drill press fence

A small build using some small vslot scrap piece which shows the versatlity of the v-slot system

Build Author

Bruce Walker

Views

7132

Build Author

Bruce Walker

Views

7132

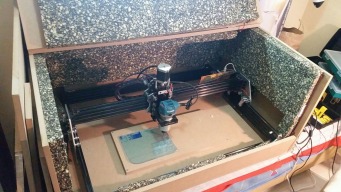

BD's Burn Box - ACRO Laser Engraver System

Two plus years in the making, I finally have a working ACRO 510 laser engraver system complete with enclosure and air filtration.

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

Build Author

Martin.Barfoed

Views

7118

Build Author

Martin.Barfoed

Views

7118

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

Home made CNC Plasma Cutter

Not completed yet but it does work, I will be changing small things as I finish the build and I have learned a lot from this build I am looking forward to finishing this one and Building another maybe larger table.

Easy to build and robust 3D printer framework

Lord willing I will be showing you how build a robust and easy to build 3D printer framework using V-Slot rails and rollers. It's a little bulky, but it has all spring tensioned rollers on all axes, and can be built entirely without custom machining on any parts. You will need digital calipers, a drill press, a carbide toothed miter saw for cutting aluminum extrusions, and lots of little screws!

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Birdie CNC

OpenBuilds CNC 500x500

Build Author

Fábio Pires

Views

7068

Build Author

Fábio Pires

Views

7068

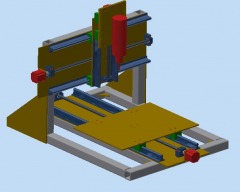

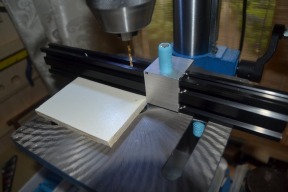

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Meister-CNC

This is a cnc router with 3 axis and a kress 1050 motor. Its 140x120cm and a homebuild with your help!

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Tommy Williamson

Views

7032

Build Author

Tommy Williamson

Views

7032

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Jose A. Molina

Views

7030

Build Author

Jose A. Molina

Views

7030

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

80watt Lasercutter, workingarea 105x52[cm], steel frame

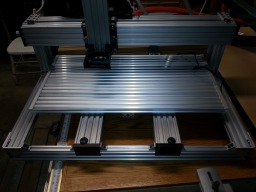

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Build Author

andrizzle

Views

7015

Build Author

andrizzle

Views

7015

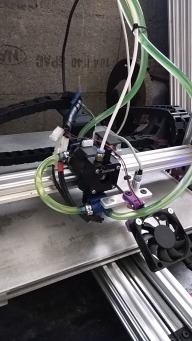

Printer1

Open source 3D printer with very powerful heated bed and light weight x axis design. Full source repository can be found here: https://github.com/a-drizzle/Printer1

Build Author

Sonny Lowe

Views

7015

Build Author

Sonny Lowe

Views

7015

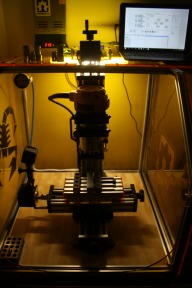

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

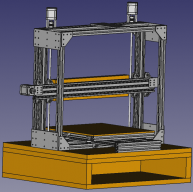

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

Build Author

Hytech2k

Views

6963

Build Author

Hytech2k

Views

6963

Micro Ox 2 x 2

Micro Ox Build

Build Author

Jose A. Molina

Views

6962

Build Author

Jose A. Molina

Views

6962

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Build Author

Stokrotka74

Views

6962

Build Author

Stokrotka74

Views

6962

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Build Author

Sonny Lowe

Views

6960

Build Author

Sonny Lowe

Views

6960

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

Build Author

Fabio Orsi

Views

6953

Build Author

Fabio Orsi

Views

6953

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Small Red OX

A small router for thin plate stock

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

Build Author

patnap71

Views

6922

Build Author

patnap71

Views

6922

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

Bruno Rivard

Views

6917

Build Author

Bruno Rivard

Views

6917

OB Heavy duty Prusa i3 "Lunar Injection"

Hell Yeah

Gauthali V2.0 DIY 3D printer

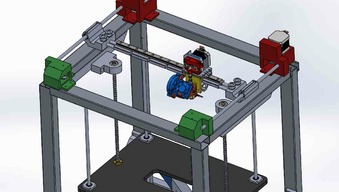

This is based on core XY kinematics. First of all, we designed a CAD model. Most of the required parts are designed by us in solidworks software, and some parts are downloaded from a web platform ‘grabcad’. After that we assembled those parts and inspected them in solidworks. The designed CAD models are frame of 470mmX392mmX545mm SBR linear guide rod, linear guide holder, lead screw, motor mounts, pulley, bed mount, idler block, timing belt clamper.

Build Author

rkugler

Views

6897

Build Author

rkugler

Views

6897

Miter Saw Stop Block

Just starting a miter saw stop system. Any suggestions appreciated.

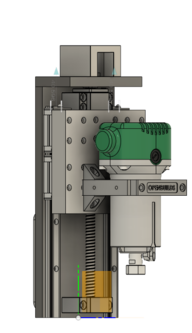

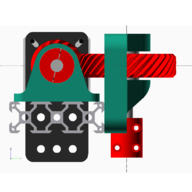

Z Axis for ACRO

Created a small Z axis for the ACRO motion system. I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. Also wanted to be able to vary the height for multiple cutting passes on some materials. Try to stick to a similar aesthetic as the original ACRO system and plates.

Build Author

txcomp

Views

6880

Build Author

txcomp

Views

6880

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

joetemus

Views

6864

Build Author

joetemus

Views

6864

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Simpl3rBot

A framing design for cantilever style printers

Build Author

CONUCON

Views

6854

Build Author

CONUCON

Views

6854

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

Large Manual 3d Printer

This is the largest printer I have found. It is also the cheapest. The reason is that it is run by hand, without computer or motors or electronics. Put an object on one side and move the 3d pen while tracing the object. Move the z dimension by turning the crank on the lab jack to move the printed copy down a notch. Be creative!

Build Author

Vunnie

Views

6812

Build Author

Vunnie

Views

6812

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

HardKnot OX 4x4

I've been working on commercial woodworking CNC's for year's under shop owner's that didn't want me to progress any further at a certain point. This is a project I've wanting to build for about 10 years now. I can't wait for the freedom to build what I know is possible without any negative input.

750x750 Plasma cutter table

It startet in May with some leftovers from a cnc router build. Now in the middle of December its 99% finish. Everything is lowcost, spend about 1600$ so far.

Build Author

OpenBuilds

Views

6747

Build Author

OpenBuilds

Views

6747

V-Slot Ventilator

The idea is to make a simple effective ventilator, studying the concept of using a simple push process with and actuator.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

Yamm (Yet another MiniMill)

First time CNC user having a good time with a MiniMill

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

Build Author

thehans

Views

6681

Build Author

thehans

Views

6681

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

Ariel Yahni

Views

6652

Build Author

Ariel Yahni

Views

6652

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

My Shapeoko Router build

I built this as it is a small portable design.

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

V-Slot Linear Actuator Bundle

v-slot linear actuator build.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)